Extruder leaking during heating

Hi,

Just put my Mk3 together, it passes all tests and seems great. If I go to print any job from the supplied SD card using the PRUSA drivers and software, as the extruder heats up some filament starts to come out, not huge amounts but enough to cause a bed levelling error sometimes, or if not that it dislodges filament from the job when it starts to print.

I keep hoping that the intro line will dislodge it (if the print job gets that far) but it doesn't, it sort of moves what has come out to the tip sides but then lifts off the PLA as it lays it down.

Any ideas? I am using standard GCODE, as I said, any print job on the PRUSA supplied SD card where we are told the prints are tested.

So what is my problem? And why did this not happen during the first layer calibration??

Regards,

David

Re: Extruder leaking during heating

Unfortunately, this is a common/known issue. Different people solve it in different ways (e.g. add some retraction at the end of the print or heat nozzle below melting point, do mesh bed leveling and then warm up nozzle to desired temp). In my case, I use tweezers to clean up any leaking during mesh bed leveling.

I think that PR is working on a workaround that will be added to Slic3r to do this automatically.

Re: Extruder leaking during heating

Thanks for the reply ... That would be good, so in the meantime I shall play around with the gcode and see if I can do something ... . That may be a good starting place .. Anyway, thanks for your help ... If there is anybody else reading this who has had same problem and came up with a solution I'd love to hear them - the more ideas the better.

Re: Extruder leaking during heating

It's working "as designed". This is something that happens on every printer. You have filament in the hot zone. For pla the extruder temp is 215. Most PLA becomes soft and a bit runny at about 190.

I usually trigger the pre-heat and let it sit for at least 5 minutes to make sure the bed is pretty evenly heated. During that time it does run a bit, I use pliers, some waste pla from a failed print, or if the x-axis is high enough my fingers and just pull it away. I just grab the lower end which is cool (enough) and not hear the extruder.

Another option as was stated was to increase the retraction at the end of a print, but you'll probably want to add 2 lines around the print to make sure it is extruding by the time the print is starting.

Re: Extruder leaking during heating

Thanks for more food for thought. It's a shame that a fairly simple thing could not have been solved by PRUSA when you consider all of the harder problems solved to mass produce 3D printers. I know it's sort of the nature of the beast thing, but not all printers do it. Frustrating.

But thanks for your help anyway. It's great to know I am part of an active community who try and help each other.

Dave

Re: Extruder leaking during heating

Here's a weird thing in relation to the problem I mentioned in my first post.

If I run a first time calibration, when the printer gets to the part where it does a print to adjust Z height, I don't get the leaking PLA problem.

So even though it's running through a normal print cycle (for all intents and purposes) and heating up just like a normal print yet no leakage.

So I'd love to get my hands on the gcode used for that print, as it obviously contains something that stops the leak.

Just something interesting for myself and others who have the leakage during normal prints.

Re: Extruder leaking during heating

I have been having the same issue of leaking filament while the bed and nozzle are heating up. I use very long tweezers to pull away the filament but it usually gets smushed around the nozzle during the level calibration.

I have always thought it would be nice to have the option to load the filament once the calibration is complete because it only runs the calibration once the nozzle and bed are heated to operating temp. This way you would load the filament and then just start printing.

Re: Extruder leaking during heating

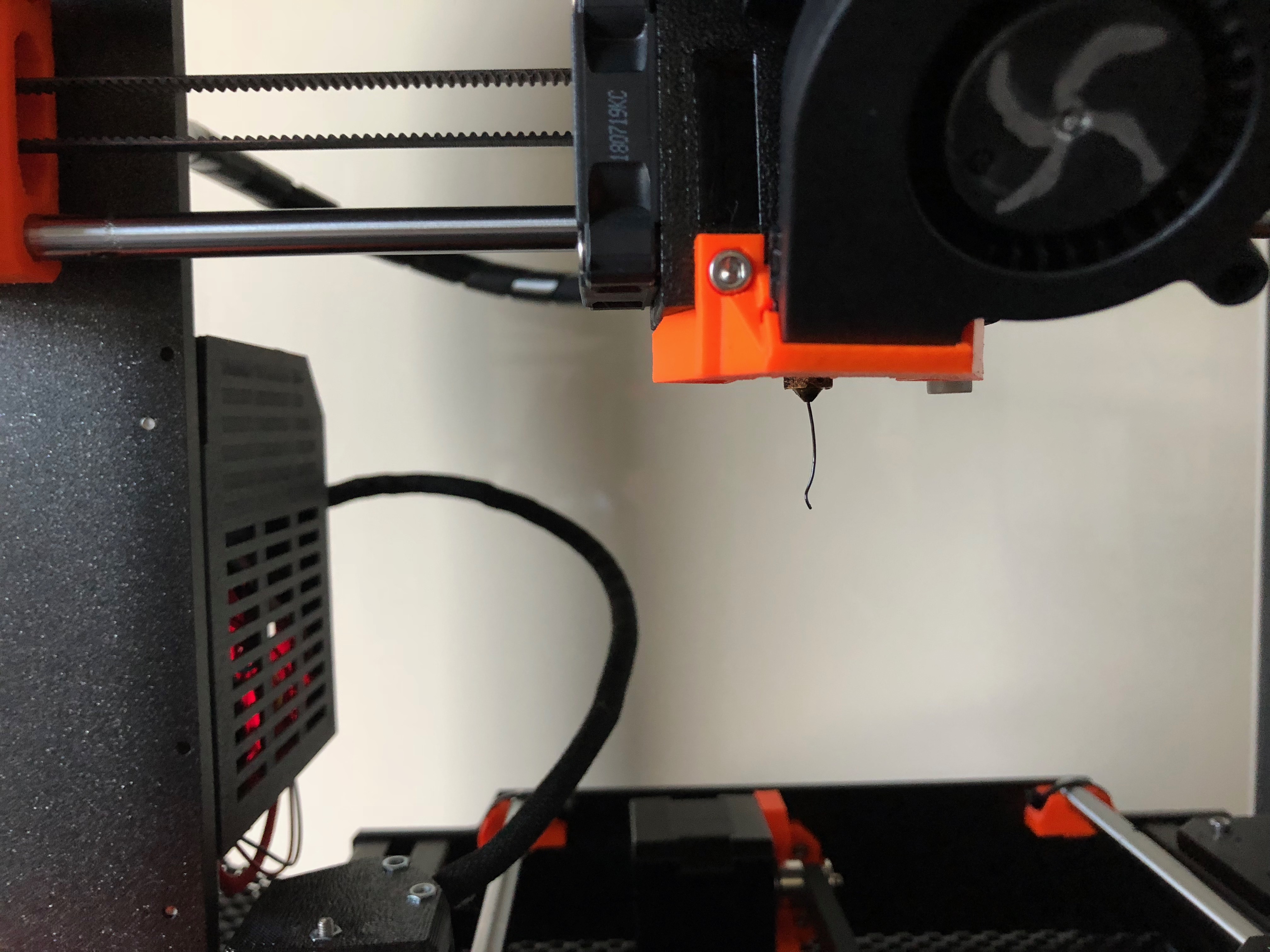

Is this a picture of what is happening?

I get these all the time. Just make sure to remove it right after I press the print button on a job. I use long tweezers and grab it right before the first movement to the mesh bed level of a print.

It helps if you set to have the extruder stop at about a z height of 100 in the end gcode of your prints so you can easily see it. If you use Slic3rPE, Put this command in the printer settings tab. custom G-code. end G-code box. G1 X100 Y200 Z100; Lift extruder for cleaning

otherwise, you have to manually move your extruder up about half way at the end of a print (which I do to have enough room to remove the build plate).

Strange women, laying in ponds, distributing swords, is hardly a basis for a system of governance!

Re: Extruder leaking during heating

It's posted elsewhere in various threads, with slight variations depending on who you get it from, but you can mostly address the problem with the following startup g-code (this is for Slic3r).

M83 ; extruder relative mode

M140 S[first_layer_bed_temperature] ; set bed temp

M104 S170; set extruder temp

M190 S[first_layer_bed_temperature] ; wait for bed temp

M109 S170 ; wait for extruder temp

G28 W ; home all without mesh bed level

G80 ; mesh bed leveling

G1 Y-3.0 Z30 F1000.0 ; go outside print area

M104 S[first_layer_temperature] ; set extruder temp

M109 S[first_layer_temperature] ; wait for extruder temp

G1 Y-3.0 Z0 F1000.0 ; go outside print area

G92 E0.0

G1 X60.0 E9.0 F1000.0 ; intro line

G1 X100.0 E12.5 F1000.0 ; intro line

G92 E0.0

It heat the bed to temp and the extruder to 170C, which is just below where PLA becomes printable. Once at temp, it levels the bed and moves to 3cm above the start point of the prime line and heats the extruder the rest of the way. The last bit of heating is quick enough that the ooze is minimal and what ooze there is gets taken care of with the prime line.

RE: Extruder leaking during heating

Here is (an even better?) solution which works for me for PET. Before this I always had the oozed PET from bed heating smeared into the noozle with ugly side effects.

M104 S190 ; set extruder temp just below melting too much

M140 S[first_layer_bed_temperature] ; set bed temp

M190 S[first_layer_bed_temperature] ; wait for bed temp

G28 W ; home all without mesh bed level

M104 S[first_layer_temperature] ; set extruder temp

G80 ; mesh bed leveling

M109 S[first_layer_temperature] ; wait for extruder temp

G1 Y-3.0 F1000.0 ; go outside print area

G92 E0.0

G1 X60.0 E9.0 F1000.0 ; intro line

G1 X100.0 E12.5 F1000.0 ; intro line

So this code initially heats the nozzle to an almost hot temperature. After the bed is heated the nozzle is set to target temperature and mesh bed leveling is started immediatly. While leveling completes the nozzle reaches target temperatue. Usually it finishes right at the time the intro lines starts. I like it this way.

RE: Extruder leaking during heating

So I'd love to get my hands on the gcode used for that print, as it obviously contains something that stops the leak.

Isn't the file you are printing exactly that "gcode" you want to get your hands on?

RE: Extruder leaking during heating

And, being pedantic:

M140 S[first_layer_bed_temperature] ; set bed temp

M190 S[first_layer_bed_temperature] ; wait for bed temp

is redundant. Like saying irregardless.

M190 S[first_layer_bed_temperature] ; wait for bed temp

Sets AND waits for the temperature.

Description

This command optionally sets a new target bed temperature and waits for the target temperature to be reached before proceeding. If the temperature is set with S then it waits only when heating.

Usage

M190 [R<temp>] [S<temp>]

Parameters

[R<temp>] |

Target temperature (wait for cooling or heating). |

[S<temp>] |

Target temperature (wait only when heating). Also |

RE: Extruder leaking during heating

yepp. very right. I was just modifying the original heat up sequence. In the end....

I also wonder, why the temperature check in the firmware is so accurate. A bed or extruder temp while heating up +-2°K off the target I would never be concerned about.

Happy printing

RE: Extruder leaking during heating

The reason for the accuracy is thermal over shoot. It's a common problem in thermal systems and it is generally accepted best practice to be patient when temp is concerned. PID calibration can actually help your system stabilize faster, and I'd suggest you run it at your most commonly used temp. It helps with under and over shoot and stabilization.

RE: Extruder leaking during heating

Ok, Here is another option to try, if desired, depending on what your situation is. I do not experience the nozzle dripping most times and I do not use the adjusted Gcode method...

Because I have very high humidity, I unload my filament after a print is done for the day. Most times, because once a print is done you have to reheat to unload the filament, I reheat the nozzle to the temperature I was last using. Unload the filament. I then usually run some Esun cleaning filament through the nozzle, using Bobstro's method, I load some E-Sun cleaning filament, and press no on the loading screen 2x times. This is done while I seal the used filament back into rubbermaid containers or load into the dehydrator. Then I unload the cleaning filament and put away.

When I am ready to print again, I preheat and load the new filament. I find that doing this, the nozzle will not drip during preheat or the mesh bed level (7X7) and I have minimized the issue. If I have multiple successive smaller prints, I do not encounter preheat dripping until after many prints ( like 5 or 6) and even then it is not that bad...

It could be something to try if desired.

Strange women, laying in ponds, distributing swords, is hardly a basis for a system of governance!

RE: Extruder leaking during heating

For those still finding this topic via search, here's a minimalist change along the lines of @jan-k123 and @william-m51, but more should work for any filament.

1. To heat the extruder only part-way until the bed is finished heating -- so you can clean the head while minimizing dribble, do the following: In PrusaSlicer Printer Setting tab, Custom G-Code

Replace (around the fifth line) in Start G-Code:

M104 S[first_layer_temperature]; set extruder temp

with

M104 S{(first_layer_temperature[0]-70)} ; set extruder temp below melting point

Note that the extruder will heat up to full temperature after the bed is at temperature but before starting the mesh leveling. This adds 30-45 seconds to the warm up, but may avoid any temperature-related issues with the PINDA sensor (i.e. if extruder is warming up as the PINDA is measuring it may affect the result).

2. (optional) - park extruder at least halfway up after finishing. (could also be done at the start, while heating)

Replace (third line from end)in End G-Code:

{if layer_z < max_print_height}G1 Z{z_offset+min(layer_z+30, max_print_height)}{endif} ; Move print head up

with

{if layer_z < max_print_height}G1 Z{z_offset+max(100, min(layer_z+30, max_print_height))}{endif} ; Move print head up AT LEAST HALF-HEIGHT

The trick here is that max(100, ....) will force the Z to rise at least 100 (10.0 cm) but won't go down if the print-head is already higher.