RE: Extruder clicking and PLA filament jammed

@peter-m26

Hi Peter, thanks for your reply. I am going to systematically try your suggestions (I feel like I tried a few of them a couple of months ago but I didn't document them properly) and get back to you!

Please consider the additional info I wrote on the post above as a reply to Joan.

Once again, thank you very much for your reply.

RE: Extruder clicking and PLA filament jammed

Hi Antonio,

how tight is your extruder tension screw?

no my Mk3S , My extruder tension screw is literally only just screwed into the nut in the Bondtech Idler trap door,

Having the screw too tight is another factor which can lead to filament jams.

Abstract thought, Have you measured your filament diameter? in these days of generally good filament we often overlook this simple check,

I got some filament recently that was really uneven in diameter, and this lead to intermittent jamming...

It was a sample from a company offering filament extruders for recycling your waste filament, and the diameter control was very poor...

I dumped the filament... and crossed that company off my list of possible suppliers!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Extruder clicking and PLA filament jammed

First of all, please bear with me on this long post. There are so many variable that I thought I’d be better of giving you guys too much information than too little.

Another info that I didn’t mention before was that yesterday I was able to print in PLA one 3D Verkstan faceshield (40min print) without a problem. When I tried printing a second one I got jams in the first 10 minutes and from then on I did cold pulls and tried different temperatures without luck, I got jams within the first 10 to 20 minutes of most attempts. The fact that the jams are occurring earlier on leads me to think that maybe I am running into an additional issue from the one I had before when PLA prints were jamming after an hour or two.

I spent most my day today doing some tests following @joantabb and @peter-m26 suggestions. Since I didn’t have any PETG left, I skipped the PETG removal step, did a cold pull of the jammed PLA I had in the extruder, heated the extruder to 260 C and extruded a few millimeters of PLA at that temperature before starting my print, as suggested by @ peter-m26. I also tightened the idle screw a notch.

Since yesterday I had some trouble printing the 3D Verkstan faceshield, I thought it might a good Idea to try it again with the setting you people recommended here. I decreased the retraction length from 0.8mm to 0.4mm and had a go. I sliced the file with 6 vertical shells and 20% infill, which, since this model is relatively thin, makes it almost 100% solid. Other than that I am using the standard Prussa Slicer “0.3 DRAFT” print profile, “Generic PLA” print profile (215/210 C), and “Original Prusa i3 MK3S” printer profile”

See image 1 for how the filament looked after the cold pull. Since I forgot to open the idler door before pulling, I think it might have come out slightly “stretched”.

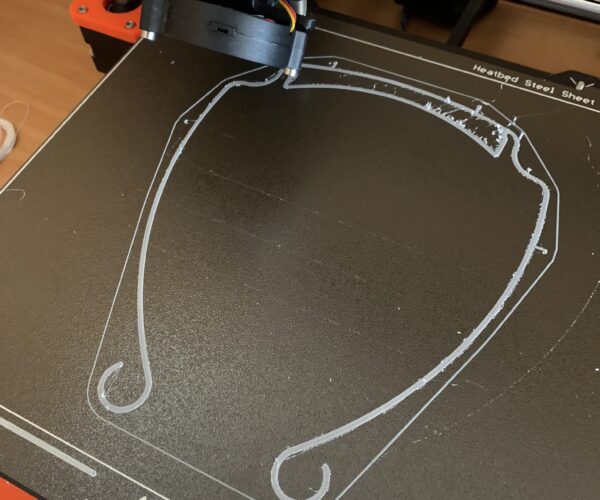

After about 10 when I came back to check the printer, it had jammed. see Image 2 for what it did print before jamming.

I did a cold pull (this time with the idle door open) after this jam, see image 3

When I screwed back the Idler door I made sure to only screw it to the point where the screw just engaged with the nut. I loaded the filament, it came out of the extruder fine. I unloaded the filament because I thought that pocking a guitar string up the nozzle could help. Reloaded the filament, it extruded as expected. I sliced the file again, this time with 0 retraction. Other than that all setting were the same.

In about 10 minutes when I came back to check on the printer, It had jammed again. So I did the cold pull routine once again, this time I felt less resistance when I poked the guitar string up the extruder.

I resliced the model, this time with retraction at 0.4mm and bumped the temperatures by 10 degrees (220/225 C). At a little more than 10 minutes in the print, I noticed the extruder had jammed again.

At this point a thought that having I thought that having the screw in the idler door so loose could as @Joan mentioned worked for her, could be causing me problems. So I tightened it up a notch and tried printing the same file again.

This time I was able to print the file and the result was pretty flawless, see image 4! When this print finished, I started another one straight away, same everything. Already In the skirt, I noticed some under extrusion and hear some clicking. So I paused the print and extruded a few millimeters of filament, it seemed to extrude a little thin at first but then it came out of the extruder normally. I resumed the print. I noticed less under extrusion but there was still some. A coup f minutes after the extruder was completely jammed.

I did a the cold pull routine, ran the guitar string up the extruder and loaded the filament before beginning to print again. Around 10 minutes in the print It jammed again. I cannot think of what might have lead to this jam. My best guess would be heat creap from the extruder but when I replaced my heater block I applied thermal paste to it and a couple of months ago I put applied some more just be sure that wasn’t causing me problems. I am going to let my printer cool down before attempting another print as a way of narrowing the problem to heat creap.

RE: Extruder clicking and PLA filament jammed

@joantabb

On the filament diameter point: I ran out of batteries for my digital caliper gauge. I ordered some new ones but it might be a couple of days until it arrives.

RE: Extruder clicking and PLA filament jammed

After letting the printer cool down, I did a cold pull and managed to print the model with no issues at all. When the print was done I started a second one right away (the nozzle didn't even reach lower than 200c) and the printer jammed already on the first layer once again. I can't think of what could be the reason for this abrupt jam... I will try printing at even higher and lower temperatures next. If there is any benchmark model (such as Benchy) that could help, I am happy to try and print it.

RE: Extruder clicking and PLA filament jammed

Without letting the printer cooldown I did cold pull and tried printing the same file at +10c extruder temperature (235/230 c) but the printer jammed on the first layer again. Here is a picture of what came out of the cold pull:

I wonder this that notch between the bulge from the nozzle and the point where the filament starts to get thinner is normal...

tomorrow I will attempt printing at temperature lower than 210 c

Any help or thoughts will we greatly appreciated.

Regards, Antonio.

RE: Extruder clicking and PLA filament jammed

Hi Antonio, those bulges in the filament seem to be occurring above the Cold end PTFE liner in the extruder.

Is your printing room very warm? are you using an enclosure?

your PLA Filament seems to be softening in the area of the Extruder bondtech gears

this could be due to excess heat... do you have a desk fan that you could blow cooling air at the extruder with?

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Extruder clicking and PLA filament jammed

Where did you apply thermal paste? Do not apply on the heater block!

E3D's own assembly instructions say "This improves heat-transfer from the heat-break threads to the heat-sink for slightly better thermal performance in marginal cases." which translates to me that its only a slightly marginal improvement and you'll be fine without it

RE: Extruder clicking and PLA filament jammed

Hi @Joan , I am not printing in a enclosure and the room i'm printing in isn't very warm. I live in Rio de Janeiro, Brazil, and the temperatures around in here at this time of year are around 25 C, give or take a couple of degrees. Having said that it does get very warm here around January/December and it's always very humid. Out of curiosity, how high could ambiente temperatures bee for printing in PLA?

As a means of testing out the ambiente temperature point, I'm attempting to print the same file having the AC of the room set to 20 C and a desktop fan pointed toward my extruder. As I said earlier, I also did the CG-Tech mod and have an additional fan mounted on the extruder stepper motor making sure it is also cool. I will get back to you later on with these results.

With the way the filament looks after a cold pull and the fact that printing PETG isn't a problem I have always suspected that the problems i'm having stems from heat traveling up my extruder and softening the filament around the Bondtech gears but I have never been able to get the root of the problem. There is thermal paste on my heatbreak and though my extruder stepper motor used to run very hot, the fan mod now keeps it cool to the touch. Would it be reasonable to think that thought the CG-Tech mod keeps the surface of the extruder motor cool, it's insides could still be running hot and causing the problem? What do you think could be causing me problems?

This picture shows what came out of the cold pull I did today, after yesterdays last jam:

@peter-m26 I I applied thermal paste only on the threaded section of the heatbreak, following the instructions in this link: https://manual.prusa3d.com/Guide/How+to+change+a+heatbreak-heatsink-heaterblock+-+MK3S-MK2.5S-MMU2S/1451

Thank you very much for you're help thus far. After having given up trying to print PLA a couple of months ago, I now feel that with your help I might me able fix this issue.

RE: Extruder clicking and PLA filament jammed

So, with the AC at 20C and a desktop fan blowing towards the extruder I attempted a first print, same settings and file as before, with the nozzle temp at 210/215. I was able to print two faceshield frames in a row. I was little late when I started the third print (extruder had cooled down) but the print turned out fine. The extruder jammed at the first layer of the 4th attempt. An interesting point is that yesterday, without the ac and the fan the desktop fan, I was not able to get past the first layers of this file at this nozzle temperature.

Since Yesterday I was having better luck with higher temperature I let the printer cool down, did a cold pull, and began printing the same file but this time with nozzle temperatures bumped up to 220/225 C. I was able to complete 2 prints in a row but the extruder jammed in the third attempt at this nozzle temperature.

I repeated the same procedure with nozzle temperatures at 230/235 C and had similar results, got to prints done and had the extruder jam on the first minutes of the third attempt.

Finally, I tried printing at 205/200 C and 195/190 C but I got jams with the first few minutes at both temperatures.

So in general I got better results than yesterday (without the ac at 20 C and a desktop fan blowing towards my extruder) but jams were still very frequent across multiple nozzle temperatures. From what I understand though, if my printer was running as it was designed to, I should be able to print in ambient temperatures over 30 C. I think it is somewhat clear I am having issues with heat creep but how is the heat going all the way up the filament in such short prints? At this point in time I feel like I have teste everything but since I haven’t figured it out yet I must have overlooked something. As I said before, I have changed my heatbreak according the official Prusa instructions, reapplied thermal paste later on just to be sure, have replaced the PTFE tube a couple of time and have done the CG-Tech mod to cool my extruder motor in case the heat was coming from there. Am I missing something?

All of cold pulls I did today looked very similar to the ones I sent pictures of before. Something I noticed which might be hard to see in the pictures is that sometimes the upper part of the filament that has been thinned by the heat (supposedly the part that is getting soft in the PTFE tube) feels even ‘flimsier’ than the lower part (which should be being molten in the heat break).

Once again, thanks for all the replies this far. I really want to figure this out to any help and suggestions will be greatly appreciated.

RE: Extruder clicking and PLA filament jammed

Hi Antonio

It's very easy to end up 'chasing your tail' in these situations as there are so many possibilities that can cause the same symptom. I recently fixed a stringing issue by tweaking my Z calibration for example when the advice was all around temperatures and retractions. If the initial recommendations don't fix a problem it's best to 'reset to defaults' and start again with hardware checks and running proven standard models. It's quite possible for example that the reason for your issue is the hothead fan having it's label facing out. I know this because I had the same issue with the filament jamming in the ptfe tube part way through prints. Start by using the Prusa instructions to change or check the PTFE tube. Clean the filament idler gears with a brush. Re-assemble the head but take care not to over tighten screws. Screw until parts meet flush without screw resistance, if resistance then re-align the part. Then screw to where you feel resistance then back off then forward to that resistance point again and then only 1/4 or 1/3 turn more. Run the full wizard after disassembling the head and the first layer calibration after your cold pulls. Filament that has absorbed humidity can also causes the filament to expand in the hothead and jam. A good check for this is to increase the temp to 170 and slowly extrude say 30cm of filament. If you see bubbles in the filament then it has absorbed moisture so needs to be dried out. The way to solve this problem is to buy a plastic sealed document storage container with the airtight lid (clip lids don't work) and put calcium chloride in the bottom in a bag or container. (Borrow a cup full from someone with a swimming pool as calcium hardness increaser is it's the same chemical). Leave it in the container for 3 days. You should never have to tweak slicer settings such as retract to fix a hardware issue like this. The final advice on this issue as regarding your process for un-loading filament. Always pre-heat the hothead and then extrude filment using >setup>Move Axis>extruder until it is running cleanly and then unload. Always unload at the end of the day and put the filament in a dry box rather than leaving it overnight. If the filament is a type that tends to drip from the head then always pre-heat and run until clear for a few CM before starting print job. If at the end of the day you cold pull your filament out and it has a wedge shape of the nozzle then you don't need to do cold pulls. With cold pulls always open the extruder door. Make sure that you let the entire head and heat exchange cool down to room temperature before you do cold pulls otherwise you will get an elongated pull. Before closing the idler door check that there is no filament dust on the extruder teeth.

RE: Extruder clicking and PLA filament jammed

I could stop the clicking doing these three actions:

1- thermal paste on the heat sink thread.

2- more pressure on the tension screw (the references for the position on the MK3, MK3+MMU2, and MK3S are differents).

3- changing the retraction parameters to:

Length: 0.4 mm

Lift: 0.2 mm

Retraction Speed: 20 mm/s

Minimum Travel After Retraction: 10 mm. After I tried to reduce and now is all right with 2.

There are now more than 10 days without problems with 10h of prints every day.

In the next days, I will try to return to the standard values.

RE: Extruder clicking and PLA filament jammed

I had this issue issue and narrowed it down to the nozzel temperature fluctuating +-6deg at times. I replaced the hot end heater cartridge and it has been running perfectly since then with temp fluctations of +- 1 deg and no jams.

RE: Extruder clicking and PLA filament jammed

In my MK2, extruder clicking while printing PLA was caused by insufficient cooling of the heat-brake.

Unfortunately, I have caused that problem by myself, by installing a centrifugal fan that I'v slowed down to reduce further the noise, but I haven't done any measurements and the cooling performance was to low.

After reinstalling normal 30mm fan, the problem with PLA printing, was gone, but the noise was back 🙁

I'm going now to redesign the adapter to attach a bigger axial fan and slow it down measuring with anemometer Testo 417.

30x10 mm fan from an extruder-clone lying around produced about 8 m3/h.

40x15 mm blowed at 20 m3/h, and required 8m3/h stream was delivered already at 6V. It was a fan identified as model 4015b 0.18A 0755-27936981.

But some other low profile 40x10mm lying around was defective, could not start on it's own and delivered only 8 m3/h.

So be aware, fans can wear out.

RE: Extruder clicking and PLA filament jammed

Hey guys, so I’ve been lurking on this thread because I’ve been having the same ‘hovering in the air’ issue recently. However, I have not been using PLA at all, it has been Filatech ABS. I was printing flawlessly and just recently in the last couple of days have I been facing this issue. I’ve tried everything including trying remixes of the Idler Door or the Fan Shroud to see if those were the issues.

But then I remebered that I changed the nozzle from a .4 hardened nozzle to the .25 brass. I had successful prints initially which is why I didn’t think about the nozzle size. I’ve switched back to the same hardened.4 nozzle and I am happy to say that my first 9 hour print (max I was hitting with this issue was the similar 2 hour mark) is still going very nicely. It is such a relief because I am relatively new to 3D printing and I thought that my MK3S was broken. Now I still think I should be able to print without any issues with a .25 nozzle but until I can figure out the issue I am content with being able to print!!!

RE: Extruder clicking and PLA filament jammed

[...] Now I still think I should be able to print without any issues with a .25 nozzle but until I can figure out the issue I am content with being able to print!!!

Next time you try the smaller nozzle, try reducing speeds considerably. A smaller nozzle produces more back pressure. This can lead to extruder skips and jams if too much filament is being fed through as the result of excessive speeds. Add in all the other problems associated with PLA and temperatures and that might explain your results.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Extruder clicking and PLA filament jammed

@bobstro

That makes complete sense. I will definitely give your recommended settings a try and hopefully all should be good. Thanks.

RE: Extruder clicking and PLA filament jammed

I haven't used my printer since July, and today (almost 3 months later) I needed to use it, and started experiencing jams. After 10 attempts and some cold pulls, it looks like the print underway now is coming out OK. Usually the first layer printed fine, sometimes several layers printed fine, but most of the time on the second or third layer, the extruder would make clicking noises and filament would stop coming out.

On my MK3S, the idler screw is about 1.5 threads beyond the nut. Before (3 months ago) it was just under 1 thread beyond the nut, about a turn of the screw after I felt it engage the spring.

Why it was working fine before, and not now, I don't know. So far the print is looking good. I've reduced the speed to 80% and raised the temperature from 205 to 210, but those things didn't help until I tightened that idler screw. All of my other settings (retraction etc.) are the PrusaSlicer defaults.

For me at least, the idler screw setting makes all the difference. It can't be too tight, but if you're experiencing unexplained jams, try tightening it just 1 turn.

The same can't be said for the idler screws on the MMU2S. Those need to be just barely tight, with the heads flush with the plastic surface. I learned that the hard way.

RE: Extruder clicking and PLA filament jammed

Well, I spoke too soon. 36 layers into the print, it jammed again. The filament just stopped moving and the extruder started clicking.

It got a lot further than before just by tightening the screw. I'll have to try the retraction adjustments next. There are a lot of retractions in this print (many small separate areas in each layer; I'm printing a bunch of pointy vertical teeth).

RE: Extruder clicking and PLA filament jammed

@anachronist

I had the same problem and I could only fix it by replacing the E3D extruder and heatbreak by a coppearhead extruder. https://www.sliceengineering.com/products/copperhead%E2%84%A2

You dont kneed the heatsink, just the headbreak and the head of the extruder.

I had three printers with problems and since the update, 0 jams, for some months