Everything is going wrong

I assembled my MK#S+, got to the First layer Calibration and may have over calibrated, as I was having problems getting the filament to stick. I started printing the tug boat, it was going well. I stepped out of the room for a while, and when I returned the boat was printed up to the deck. The nozzle was about two inches above the project and printing in the air, with no filament coming out.

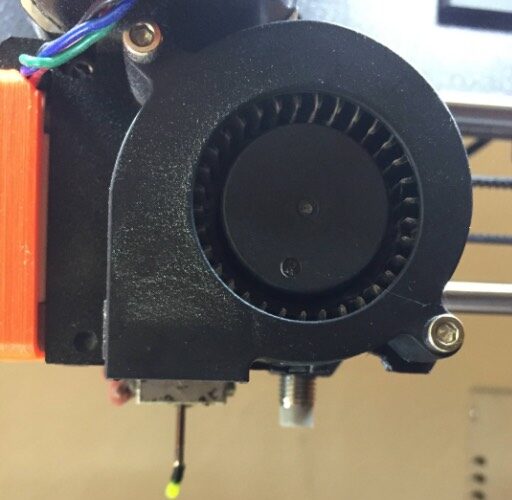

I wire brushed the nozzle and tried to do the First layer calibration and nothing came out and I got a clicking noise, I also noticed the front fan was not moving.

I tried to take the filament out and it broke. I assume the nozzle is not heating.

What do I do to fix my machine?

RE: Everything is going wrong

You had a jam. I suspect that your hotend might have been assembled wrong or your idler screw was too tight.

You are going to have to disassemble the hotend and remove the filament. Be careful with the wiring. Once disassembled, follow the directions carefully to reassemble.

--------------------

Chuck H

3D Printer Review Blog

RE: Everything is going wrong

https://help.prusa3d.com/en/article/clogged-nozzle-hotend-mk3s-mk2-5s_2008

If you're having problems with calibration post a picture of your first layer here and we'll try and diagnose it.

Cheerio,

RE: Everything is going wrong

@cwbullet

Just to let you know: Everything but the heat bed was working. I could print small objects, but larger projects would not stick to the bed. I kept reducing the size of the media extrusion, I think to where it was too thin.

I tried to allow more media to flow after I caught the printer painting the air with no media after successfully printing the tug boat up to the deck. I tried to unload the filament (still using what was sent in the kit), and it started coming out then broke. I have tried to unload and load the piece that is sticking out and nothing happens (I do hear clicking when unloading, but the filament does not come out.

Do you still think tearing the extruder apart may help?

RE: Everything is going wrong

[...] I tried to unload the filament (still using what was sent in the kit), and it started coming out then broke. I have tried to unload and load the piece that is sticking out and nothing happens (I do hear clicking when unloading, but the filament does not come out.

Before you go tearing the extruder apart, hat the nozzle up and try poking a rod (a 1.5X150mm length of brass rod from a hobby store works well) down through the filament feed, past the open extruder gears, and down into the PTFE tubing. Removing the nozzle may help, and poking upwards through the hotend might also help. I've got notes on the procedure here that might be helpful. This has saved me many teardowns.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Everything is going wrong

I opened up the extruder door and there was some melted filament. Thanks. I did a first layer calibration and increased the diameter of the filament laydown to 0.999. I started a file and it bunched up on the bed and the nozzle picked what was on the bed and dragged it around. Do I need to change the setting?

RE: Everything is going wrong

It looks like you cleared the clog, so congrats on that.

Sorry, but I'm not sure what you mean by "increased the diameter of the filament laydown to 0.999". Do you mean the Live-Z adjustment?

That Live-Z looks about right, but just to be certain, try using Jeff Jordan's "Life Adjust" procedure for calibrating your Live-Z setting. It is much easier to use and understand than the onboard routine and much easier to make mid-print adjustments accurately with. In general, start high (less negative) and work lower (more negative) in large increments (e.g. 0.1mm) until the filament starts to stick on its own. When you've got your Live-Z setting adjusted properly, you should be able to gently rub the extruded lines on the PEI surface without dislodging them. Then start lowering (more negative) the level until there are no gaps between layers. You should not be able to peel the lines apart after printing, but the top should be regular.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Everything is going wrong

@bobstro

Yes Live Z. I think I am getting close to things going well, thanks everyone. I hope I can get the adjustments correct this time.

RE: Everything is going wrong

OK, I have things working, except to get the filament to stick to the plate. I have gone from 0.100 - 1.000 on the Z adjustment. Should I go higher?