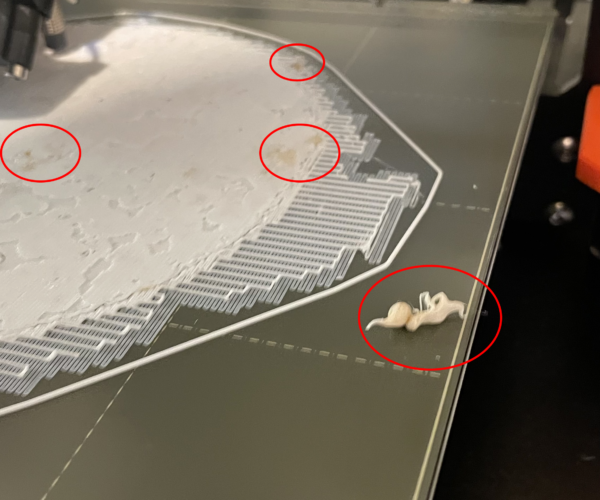

Do y'all know why I am getting these blobs in my print?

Hey y'all,

I have a Prusa Mk3S+ and I am printing PLA @ 215 C nozzle and 60 C bed temperature. I recently had to replace the nozzle because it was too much to clean and unclog it.

The good news is the printer is working again. The not so good news is that I am getting these weird blobs in the print and I have no idea why.

Would love to hear your thoughts!

Please show us a picture of your nozzle installation.

Cheerio,

@thedsk

based on your image and description of events there is a High likelihood that your nozzles isn't installed properly and is leaking around the heater block.

Regards

Swiss_Cheese

The Filament Whisperer

You may be right

I changed the nozzle out with a different one which had a different shape and it was a pain to calibrate the z offset again. I have been researching as well and you may be right, it could be the leakage.

I have ordered these and will install them as soon as they deliver https://www.amazon.com/gp/product/B086W25579/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1

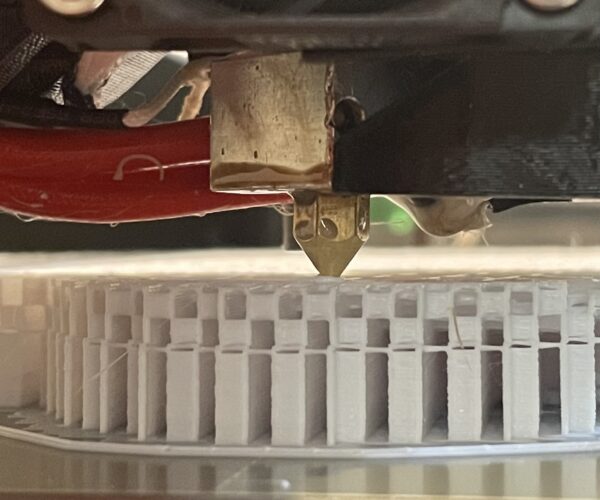

the hotend was a bit loose

Here you go. I realized the heating block came undone when I was installing the new nozzle. I have tightened it now and started the print again. Will report back.

Please show us a picture of your nozzle installation.

Cheerio,

Figured it out.

Apparently the nozzle I installed is not compatible with the hotend and hence the filament is oozing out of it. Waiting for the compatible nozzles to be delivered.

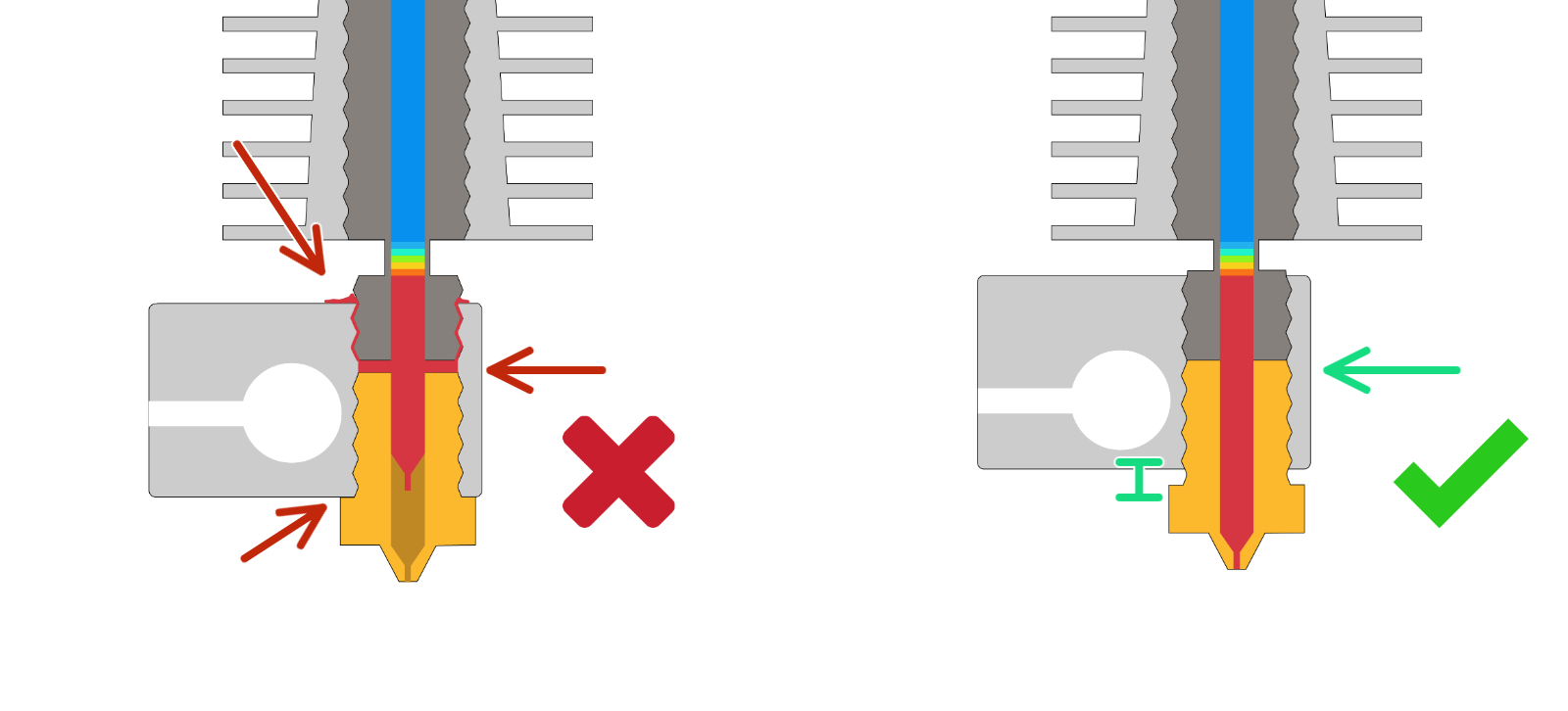

E3D hotend assembly guide is good

Raise Z so you can get a good look and remove the part cooling fan and inspect the top of your heater block. Look for a puddle of filament at the top of the block and likely dripping down the sides. If you see that, you definitely have a filament leak due to improper nozzle tightening. The E3D hotend assembly guide is very good. Pay careful to the bit about screwing in the nozzle flush, backing it out to the desired < 1mm gap, THEN hand-tightening the heatbreak up against the nozzle. The important bit is that, when properly tightened, it should be impossible to tighten the nozzle flush up against the block.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: One of two things:

One of two things:

- Nozzle is not tightened against you heatbreak.

- Your heatbreak is not inserted far enough in the heat block to allow the nozzle to close the gap.

--------------------

Chuck H

3D Printer Review Blog

@thedsk

I'm glad we were able to help, this should be a fairly easy fix, I have found it best just to stick with the Genuine E3D nozzles they are reasonably priced and no quality or compatibility issues in my experience, on amazon you will sometimes find counterfeit products, so watch for that.

Looks like Bob, and Charles have provided you with some good info for the new nozzle install, you should be all set when the new nozzles arrive.

Good Luck,

Swiss_Cheese

The Filament Whisperer

—

You are right about both. At first, I noticed the heat lock being loose so I cranked it down and I am still having those blobs so I am thinking it has to do with the incompatible nozzle.

The compatible ones will be delivered tomorrow. Will report back soon!

One of two things:

- Nozzle is not tightened against you heatbreak.

- Your heatbreak is not inserted far enough in the heat block to allow the nozzle to close the gap.

Realizing the difference in the nozzle types the hard way

The nozzle on the right is from the Prusa

the hotend was a bit loose

Here you go. I realized the heating block came undone when I was installing the new nozzle. I have tightened it now and started the print again. Will report back.

the nozzle in your picture looks like a Mk8 nozzle, which has a shorter screw thread and a longer nozzle... they can be made to work, at a pinch, but it's not really worth the effort.

there are many nozzles manufactures specifically for the e3Dv6 hot end

I have successfully used e3D, OEM nozzles,

Cheap as Chips chinese bulk Brass nozzles

Chinese stainless nozzles, and I am currently using Nozzle Z, which is a cost effective hardened nozzle https://zaribo.com/nozzles/471-5006-top-quality-hardened-175-nozzle-for-e3d-v6-by-zaribo.html#/87-nozzle_width-04mm.

If you are considering trying different size nozzles I suggest you stick to 0.25mm, 0.4mm, 0.6mm and 0.8mm, because Prusa Slicer has preset profiles for these values.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK