Defects when using 0.8mm nozzle

Hello there!

I am just learning about 3D printing and I am doing my first printings.

With the 0.4mm nozzle (0.2mm layer height) everything works great.

I bought the E3D Nozzle Pro Pack and I am having problems with the 0.8mm Brass nozzle.

Hardware/software:

Original Prusa i3 MK3 (bought the assembled one)

Firmware: 3.3.1

Bundled Prusa PLA gray filament

Ubuntu 18.04

Slic3r PE 1.40.1+linux64

Changes done in Slic3r:

Print Settings - Layers and perimeters - Layer height

Set Layer height and First layer height to 0.4mm.

Print Settings - Layers and perimeters - Vertical shells

Spiral vase checked.

Print Settings - Advanced - Extrusion width

Set Top solid infill to 0.8mm.

Set the rest of parameters to 0.88mm.

Filament Settings - Filament - Temperature - Extruder

Set both parameters to the same value. Tried different values.

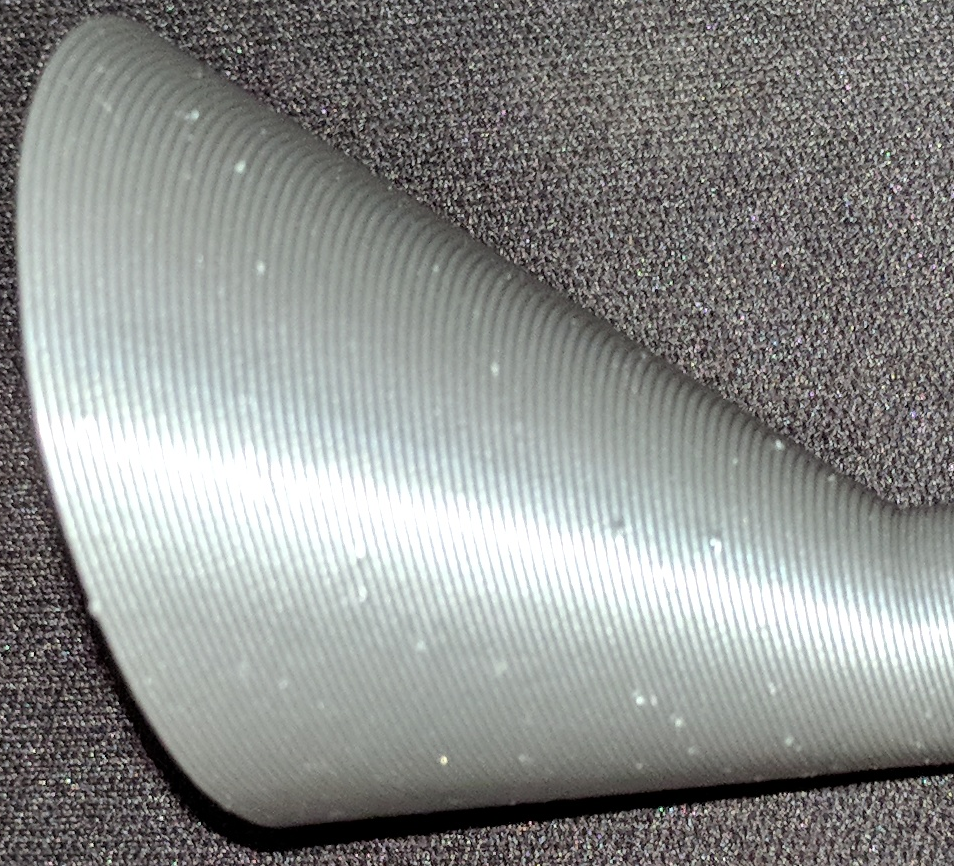

With the default temperatures, there are defects like the following on several sections of an object:

When increasing the temperature to 220, I see the same kind of defects but on fewer sections.

When increasing the temperature to 225, I don't see such kind of defects, but other kind appears:

(this is not related to seams because Spiral vase is checked)

If I see the object with a light behind it, I see that those bumps are small holes.

I have searched for recommended values or Slic3r PE presets for a 0.8mm nozzle with 0.4mm layer height, but I haven't been able to find such info.

Looks like the most common recommendation is to increase the temperature little by little. So, I could try 224, 223, etc., but I don't think that is the right path to follow because:

1. I don't feel such small changes would give me a permanent solution. Is this that sensitive?

2. I will use other filament brands and colors and I read that event different colors from the same brand produce different results.

I can see that Slic3r PE doesn't include presets for 0.8mm nozzles and the highest layer height is 0.2mm even for a 0.6mm nozzle.

If someone is using a 0.8mm nozzle with higher layer heights successfully and could give some recommendations, that would be great.

If my printer is not intended for such dimensions (Is that the reason for not including presets in Slic3r PE?), it will be OK for me.

However, I think my lack of experience is the real issue here. 🙂

TIA

Re: Defects when using 0.8mm nozzle

good morning Craftsman,

the standard E3d heaterblock has a limited capacity for melting plastic, 0.8mm nozzle with 0.4mm layer height may be exceeding this limit. (depends on travel speed, extrusion width etc.)

is there a particular reason that you want the big nozzel ?

you may be better changing to the E3d Volcano hot end, it screws on to the heeatsink in place of the standard v6 heatblock, and uses longer nozzles.

this mod creates a larger melt zone, which can handle larger nozzles and larger layer heights than the standard V6 heatblock.

the volcano hot end uses the same heater element and thermistor as the standard hot end, but you should expect slower initial heating time,

you will need to re run the PID settings,

you will need to change the part cooling nozzle to match the extra length of the volcano hot end, and

you should revise the firmware to address the reduced Z height available (there is a revised extruder assembly that adresses this extra length of the volcano, and I understand that the Skelestruder also has a set of parts for the volcano hot end...)

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Defects when using 0.8mm nozzle

[...] If I see the object with a light behind it, I see that those bumps are small holes.

I have searched for recommended values or Slic3r PE presets for a 0.8mm nozzle with 0.4mm layer height, but I haven't been able to find such info.It can be hard to find good information. Part of that has to do with what people are printing. Settings that work well for detailed miniatures might not work for large functional parts and vice-versa.

I'm happy to share my experience. I'm no expert, but I've had good luck with materials and nozzle sizes for my limited testing.

The key to success for me has been the max. volumetric speed settings in Slic3r. The E3D V6 extruder can handle up ~11.5mm^3/s of material. The amount being processed will depend on a complex combination of nozzle bore, layer height, extrusion width, speed, acceleration, jerk and no doubt other factors. Nozzle size plays into this in a major way. When I loaded Slic3rPE 1.40.1+, the setting for Print Settings->Speed->Autospeed (advanced)->Max volumetric speed was 0. I've set it to 11.5 to match the E3D V6 spec. This sets a maximum amount of filament to be processed independent of speed settings, essentially a limiter on the other speed settings. There are also limiters set on a per-material basis under Filament settings->Advanced->Print speed override->Max volumetric speed. For PLA, the Prusa profiles have this set to 15mm^3/s. For smaller nozzle sizes, this may be less of an issue, but I suspect this setting might be over-running the extruder capabilities. That might explain your gaps.

As an experiment, you could tweak either of these settings. I do this whenever I'm printing a new material and encounter those extruder clicks and jams. In my admittedly limited experience, throttling via these settings has resolved all of my problems. This the the biggest reason I'm using Slic3rPE as my primary slicer. These settings also avoid the need to tweak individual speeds. You can print up to the speeds you set, but only so long as the maximum extrusion rate is not exceeded.

You might be able to see if this is an issue in Slic3r. Slice your print as normal, then select the Preview button at the bottom and set View at left to Volumetric flow rate. If you are seeing rates above 11.5mm^3/s -- something very likely with a 0.80mm nozzle -- then you may be "breaking the speed limit" of the extruder. By setting 11.5 printer-wide, I often see the 0.80mm and 1.00mm nozzles pushing the maximum through. Change the View option to Speed and you'll see that speeds are being limited. In my experience, larger nozzles will be capped at 15-25mm/s speeds.

[...] I can see that Slic3r PE doesn't include presets for 0.8mm nozzles and the highest layer height is 0.2mm even for a 0.6mm nozzle.

I think this is why Prusa has pared back the number of supported layer heights and nozzle sizes. If they provide one, they have to support it. You can configure whatever you want, but they can't provide support.

If someone is using a 0.8mm nozzle with higher layer heights successfully and could give some recommendations, that would be great.

These are just my suggestions after a few months of tinkering. Hopefully someone smarter will come around. I can say that I've been able to deal with any extruder jams and clicks doing things this way, for what that's worth. In short, once you get above a 0.60mm nozzle, you're already pushing up against the E3D V6 extruder capacity. If you really need more, as Joan suggests, the Volcano can push something like 25-30mm^3/s.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Defects when using 0.8mm nozzle

Hi Joan,

I hope you are doing very well.

good morning Craftsman,

the standard E3d heaterblock has a limited capacity for melting plastic, 0.8mm nozzle with 0.4mm layer height may be exceeding this limit. (depends on travel speed, extrusion width etc.)

is there a particular reason that you want the big nozzel ?

Thanks for letting me know about the E3D heaterblock limitations, I wasn't aware of that.

But it is good to know that there are options. 🙂

To be honest, the main reason for printing with the big nozzle is speed. If I were printing stuff for me only, speed wouldn't be so important, but I pretend to sell what I print.

I know that this has an impact on quality. However, for some objects, like vases, I like how the higher layers look.

For other objects I will use smaller nozzles.

Also, for the moment I am creating decorative objects only but later, when I have more experience and knowledge, I want to create functional objects with PETG, and I want the higher layers in order to create stronger objects.

you may be better changing to the E3d Volcano hot end, it screws on to the heeatsink in place of the standard v6 heatblock, and uses longer nozzles.

this mod creates a larger melt zone, which can handle larger nozzles and larger layer heights than the standard V6 heatblock.

the volcano hot end uses the same heater element and thermistor as the standard hot end, but you should expect slower initial heating time,

you will need to re run the PID settings,

you will need to change the part cooling nozzle to match the extra length of the volcano hot end, and

you should revise the firmware to address the reduced Z height available (there is a revised extruder assembly that adresses this extra length of the volcano, and I understand that the Skelestruder also has a set of parts for the volcano hot end...)

I had read about the Volcano hot end but I was a little scary for calibrating the hardware because of the larger nozzles.

Thanks to your answer I discovered that I can modify the firmware and compile it. I feel more comfortable doing that.

I will consider buying it.

The Skelestruder looks awesome!, but I think I don't have the necessary skills yet.

I will investigate if somebody in my country has worked with it.

Thanks a lot for your help.

Re: Defects when using 0.8mm nozzle

I Bob,

I hope you are doing great.

The key to success for me has been the max. volumetric speed settings in Slic3r. The E3D V6 extruder can handle up ~11.5mm^3/s of material. The amount being processed will depend on a complex combination of nozzle bore, layer height, extrusion width, speed, acceleration, jerk and no doubt other factors. Nozzle size plays into this in a major way. When I loaded Slic3rPE 1.40.1+, the setting for Print Settings->Speed->Autospeed (advanced)->Max volumetric speed was 0. I've set it to 11.5 to match the E3D V6 spec. This sets a maximum amount of filament to be processed independent of speed settings, essentially a limiter on the other speed settings. There are also limiters set on a per-material basis under Filament settings->Advanced->Print speed override->Max volumetric speed. For PLA, the Prusa profiles have this set to 15mm^3/s. For smaller nozzle sizes, this may be less of an issue, but I suspect this setting might be over-running the extruder capabilities. That might explain your gaps.

Great info to know! I have been tweaking the nozzle temperature only.

As an experiment, you could tweak either of these settings. I do this whenever I'm printing a new material and encounter those extruder clicks and jams. In my admittedly limited experience, throttling via these settings has resolved all of my problems. This the the biggest reason I'm using Slic3rPE as my primary slicer. These settings also avoid the need to tweak individual speeds. You can print up to the speeds you set, but only so long as the maximum extrusion rate is not exceeded.

Tweaking the individual speeds is something I have been trying to avoid. I need to learn more before doing it.

Trying different Max volumetric speed values only will make things easier. 🙂

You might be able to see if this is an issue in Slic3r. Slice your print as normal, then select the Preview button at the bottom and set View at left to Volumetric flow rate. If you are seeing rates above 11.5mm^3/s -- something very likely with a 0.80mm nozzle -- then you may be "breaking the speed limit" of the extruder. By setting 11.5 printer-wide, I often see the 0.80mm and 1.00mm nozzles pushing the maximum through. Change the View option to Speed and you'll see that speeds are being limited. In my experience, larger nozzles will be capped at 15-25mm/s speeds.

This is very valuable for me. 😀

I will try it and come back with the results.

These are just my suggestions after a few months of tinkering. Hopefully someone smarter will come around. I can say that I've been able to deal with any extruder jams and clicks doing things this way, for what that's worth. In short, once you get above a 0.60mm nozzle, you're already pushing up against the E3D V6 extruder capacity. If you really need more, as Joan suggests, the Volcano can push something like 25-30mm^3/s.

I am really happy with your recommendations.

Thanks a lot for sharing your experience.

Re: Defects when using 0.8mm nozzle

You might be able to see if this is an issue in Slic3r. Slice your print as normal, then select the Preview button at the bottom and set View at left to Volumetric flow rate. If you are seeing rates above 11.5mm^3/s -- something very likely with a 0.80mm nozzle -- then you may be "breaking the speed limit" of the extruder. By setting 11.5 printer-wide, I often see the 0.80mm and 1.00mm nozzles pushing the maximum through. Change the View option to Speed and you'll see that speeds are being limited. In my experience, larger nozzles will be capped at 15-25mm/s speeds.

This is very valuable for me. 😀

I will try it and come back with the results.

Hi bob!

So, everything is working fine now. 🙂

It turned out that the first kind of defects were caused for a mistake I made:

I hadn't set Printer Settings->Extruder 1->Nozzle diameter to 0.8 in the 0.8 nozzle preset I had created.

After setting it to 0.8 and using the default Prusa PLA filament values (except for Max Volumetric speed), the object was printed OK.

I set the Max Volumetric speed (MVS) to 11.5mm^3/s in both Print Settings and Filament Settings, but I suspect this wouldn't have had an effect on the results because the highest MVS, after slicing, was 2.407 and the whole object was being displayed in dark blue which corresponds to MVS = 1.701 in my Slic3r settings.

I am not sure because I have not tested with the default MVS values yet.

It looks like Spiral vase mode is big nozzles friendly. Is this true in general?

I am tempted to increase the speed little by little and see what happens.

Now, I am creating a multi-part object and, for the parts I can't use Spiral vase mode, I saw that some sections were exceeding 11.5 up to 15 with the default values, as you mentioned. And yes, problems appeared on those sections.

I set MVS to 11.5 and things went better, but I had to decrease it to 10 to get and object without defects.

This has saved me a lot of time, and it will continue.

Thanks again!

Re: Defects when using 0.8mm nozzle

[...] So, everything is working fine now. 🙂

Glad to hear it!

It turned out that the first kind of defects were caused for a mistake I made:

Yes, that would definitely make a difference. Every slicer seems to require that information in different screens.

I hadn't set Printer Settings->Extruder 1->Nozzle diameter to 0.8 in the 0.8 nozzle preset I had created.

After setting it to 0.8 and using the default Prusa PLA filament values (except for Max Volumetric speed), the object was printed OK.

I set the Max Volumetric speed (MVS) to 11.5mm^3/s in both Print Settings and Filament Settings, but I suspect this wouldn't have had an effect on the results because the highest MVS, after slicing, was 2.407 and the whole object was being displayed in dark blue which corresponds to MVS = 1.701 in my Slic3r settings.

Very possibly. That's the beauty of the MVS approach: It only slows things down when it needs to. Otherwise, you can print at your desired speeds without concern.

[...] It looks like Spiral vase mode is big nozzles friendly. Is this true in general?

Yes, very true. A big nozzle combined with a tall layer height and extrusion width allows sprial mode prints to go very quickly and yet produce stable parts.

[...] Now, I am creating a multi-part object and, for the parts I can't use Spiral vase mode, I saw that some sections were exceeding 11.5 up to 15 with the default values, as you mentioned. And yes, problems appeared on those sections.

That was my experience as well. MVS is transparent until you hit the limits, then kicks in without a lot of tuning and configuration. It's really important when you use filled or exotic filaments. The MVS for PETG is 8, for Colorfabb XT-CF20 is 1. Others vary between 5-10. It's nice to make one change for the filament and not worry about it elsewhere.

I set MVS to 11.5 and things went better, but I had to decrease it to 10 to get and object without defects.

This has saved me a lot of time, and it will continue.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan