Dat1darkrai's printer

Heyyo everyone!

My printer has been assmebled and so i'd figured i would make a thread to keep track of the progress from being built to printing, as well as to contain all my issues to one thread so i dont clog up the forum with multiple threads.

SOLVED: First issue i would like to address is my printer is failing the self test as it says there is an error with axis length X.

I checked the actual axis and the print head reaches both sides with out any problem. I noticed that the printer was skipping a bit when the print head was heading to the right side of the printer and not the left. Could that be it?

SOLVED: My extruder motor is not urnning, i had no problem reaching the live z calibration step but i noticed no filament was coming out and that the motor was not running

ISSUE: Im having trouble with the Z calibration. The value has to go beyond -1.2 to reach a optimal filament "squish"

Semi-newbie into 3d printing to make my prop making life easier as well as to use 3d printing for engineering.

Re: Dat1darkrai's printer

Probably not the reason but eventually you will need to check this. what's your belt tension? You can check this on the lcd -> support

Re: Dat1darkrai's printer

Probably not the reason but eventually you will need to check this. what's your belt tension? You can check this on the lcd -> support

X belt says 253 and Y belt says -1. Im assuming that is not where it should be? I saw some numbers like 290 on the forum somewhere

Semi-newbie into 3d printing to make my prop making life easier as well as to use 3d printing for engineering.

Re: Dat1darkrai's printer

That's normal in this case. The self-test is failing before it gets to the Y-axis so it's just using a default/placeholder value.

And yes, the X-axis carriage shouldn't be skipping. It should move smoothly from one side to the other. My first guess would be that you have a bad bearing. With the steppers disabled (or the printer off) try moving it from side to side by hand. Does the movement feel rough?

Also, take a careful look at the smooth rods. Do you see any pits or gouges in them?

Re: Dat1darkrai's printer

That's normal in this case. The self-test is failing before it gets to the Y-axis so it's just using a default/placeholder value.

And yes, the X-axis carriage shouldn't be skipping. It should move smoothly from one side to the other. My first guess would be that you have a bad bearing. With the steppers disabled (or the printer off) try moving it from side to side by hand. Does the movement feel rough?

Also, take a careful look at the smooth rods. Do you see any pits or gouges in them?

The smooth rods dont have any thing on them. they are smooth. The print head moving side to side doesnt fell rough, it just skips when i move it

BIG EDIT: Welp i figured out the problem. I didnt tighten down the locking screws on the bearings and so it was causing some some slipping

Semi-newbie into 3d printing to make my prop making life easier as well as to use 3d printing for engineering.

Re: Dat1darkrai's printer

Awesome! Everything's running smoothly, then?

Re: Dat1darkrai's printer

Awesome! Everything's running smoothly, then?

Up until now, yes lololol

My extruder motor is not turning at all. I got to the part on the live z adjustment in the setup and noticed the gears were not moving what so ever and i looked to see if the extruder was connected to the board and it was. not sure what else. Is the gear that is attached to the motor supposed to spin freely? if so, mine is very sturdy and does not want to move

Semi-newbie into 3d printing to make my prop making life easier as well as to use 3d printing for engineering.

Re: Dat1darkrai's printer

Oof. 🙁

I'm not 100% on this, but I'm fairly certain this is how it should be: the idler gear should spin freely when the cover is open (that much I do know for sure :)). I believe that as long as the printer is on the fixed gear will be held in place to prevent the loaded filament from slipping. You should be able to move it with some force with the printer off, though.

Re: Dat1darkrai's printer

Oof. 🙁

I'm not 100% on this, but I'm fairly certain this is how it should be: the idler gear should spin freely when the cover is open (that much I do know for sure :)). I believe that as long as the printer is on the fixed gear will be held in place to prevent the loaded filament from slipping. You should be able to move it with some force with the printer off, though.

Ok i have it how you mentioned. Idler gear runs free and the gear on the motor spins with a little bit of force when the printer is off When i had removed the idler gear, i put a piece of filament in and realized in needs to go pretty deep, deeper than i originally thought. could this be a reason for it not working? Maybe because it doesnt detect any filament so it wont run?

Semi-newbie into 3d printing to make my prop making life easier as well as to use 3d printing for engineering.

Re: Dat1darkrai's printer

The motor will still spin regardless of whether there's filament loaded or not. The filament sensor just pauses the print if it trips, it doesn't affect motor operation.

Does the motor run if you go into Menu > Settings > Move Axis > Extruder? If not, try plugging another motor into the extruder motor plug and see if that one will move. As long as everything's plugged in securely I'm thinking there might be an issue with the E-axis motor or the EINSY. >_<

Re: Dat1darkrai's printer

The motor will still spin regardless of whether there's filament loaded or not. The filament sensor just pauses the print if it trips, it doesn't affect motor operation.

Does the motor run if you go into Menu > Settings > Move Axis > Extruder? If not, try plugging another motor into the extruder motor plug and see if that one will move. As long as everything's plugged in securely I'm thinking there might be an issue with the E-axis motor or the EINSY. >_<

I got it working. I had to push the filament all the way in and it ended up working

The next problem im facing is getting the z value correct. Im not sure what to do as with my current prinda probe height, i have to set the z offset to somewhere around -1.1 for a a proper first layer. I read in the manual that it shouldnt exceed -1.

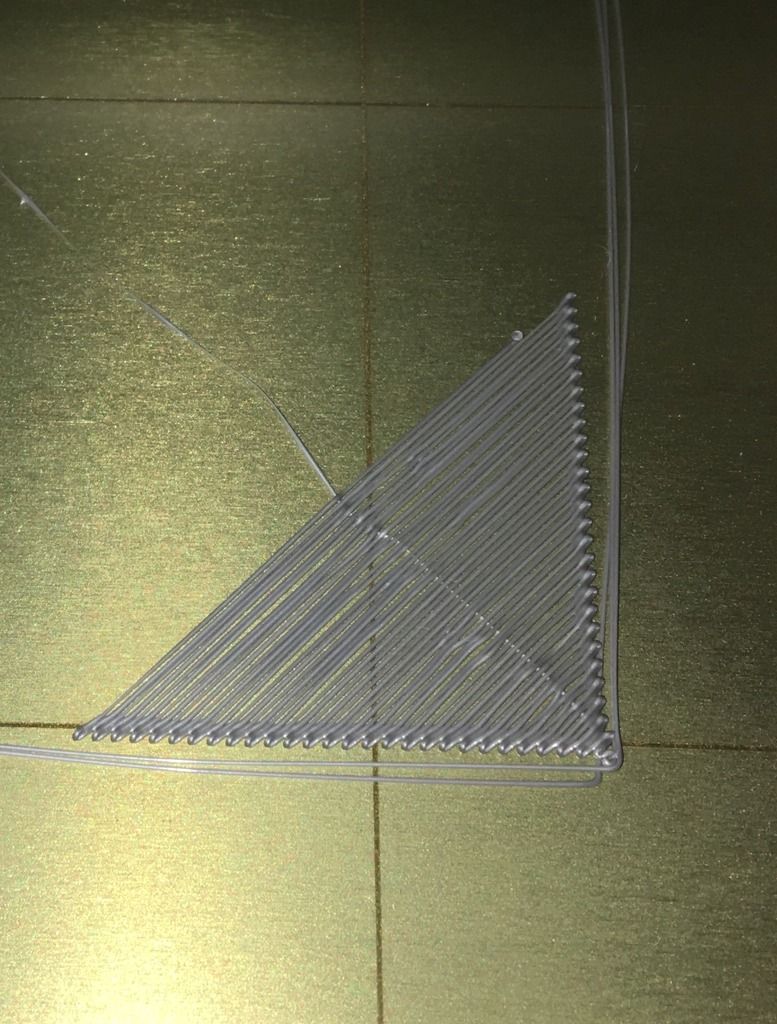

Here is a photo of the Z value at -500 with jeffjordan's first layer print .gcode.

Semi-newbie into 3d printing to make my prop making life easier as well as to use 3d printing for engineering.

Re: Dat1darkrai's printer

Glad you got the extruder working!

As for the Z height, you'll have to lower your PINDA probe slightly. The width of a zip tie (placed flat) with the nozzle just over the bed apparently works in most cases, but I've read a few accounts where the probe had to be lowered very slightly to get the Z offset up to acceptable levels.

Re: Dat1darkrai's printer

Glad you got the extruder working!

As for the Z height, you'll have to lower your PINDA probe slightly. The width of a zip tie (placed flat) with the nozzle just over the bed apparently works in most cases, but I've read a few accounts where the probe had to be lowered very slightly to get the Z offset up to acceptable levels.

I did just that and it read the first point fine but when it got to 2/4, it failed. Starting the process ( the wizard) from square 1 now to see if that fixes it.

EDIT: seems like it has fixed it. doing z calibration now with updated prinda probe height

Semi-newbie into 3d printing to make my prop making life easier as well as to use 3d printing for engineering.

Re: Dat1darkrai's printer

Glad you got the extruder working!

As for the Z height, you'll have to lower your PINDA probe slightly. The width of a zip tie (placed flat) with the nozzle just over the bed apparently works in most cases, but I've read a few accounts where the probe had to be lowered very slightly to get the Z offset up to acceptable levels.

I got a succesful first print. I printed the batarang that is on the SD card and it printed fine in my opinion. Theres 2 little areas with some weird surface issues and the print warped on the vary far edges. Since my printer is like this, is it good go then?

See photo from link below:

https://imgur.com/a/t0SeUYu

Semi-newbie into 3d printing to make my prop making life easier as well as to use 3d printing for engineering.

Re: Dat1darkrai's printer

Awesome! Yeah, I think you're good to go.

You should be able to solve the adherence issues with some isopropyl alcohol (at least 90%)* or a little bit of dish soap and water. PEI is really sensitive to skin oils and such. For larger prints, as well as ones with minimal build plate contact, you might need to use a thin layer of PVA-based glue stick (the MK3 should have included a stick. Elmer's vanishing purple also works well) to assist with adhesion.

Oh, very important random note: if you ever print any copolyesters (PETG, colorFabb nGen/XT/HT, etc), make sure to apply some glue stick. Those materials stick too well to PEI. Without using something as a separation layer it could pull a chunk of PEI off of the sheet.

Happy printing!