Curling support first layer

I'm struggling to use support material as the corners peel up instantly when the first layer is going down. As soon as the head changes direction 1-2mm worth of material curls up making the first layer useless. Large flat shapes print ok but single lines curl curl instantly.

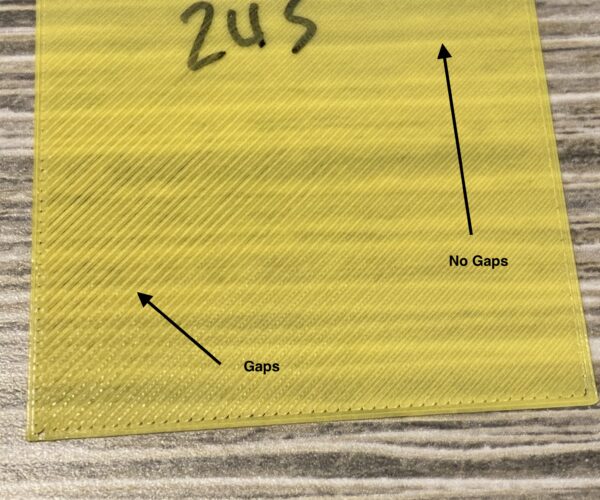

I've gone through a printed a bunch of test squares. I'm unsure if my z offset is correct as for one corner of the square I have good coverage but then in other sections I have gaps between appearing, however if I go any lower it starts to look too low, in fact looking at the image of the supports layer to my eyes it looks too low in some areas but fails to stick in others.

I suspect either a problem with the nozzle or me misunderstanding what I should be looking for when setting the layer height. Any assistance in troubleshooting this issue or explaining to me what I'm missing here would be greatly appreciated.

RE: Curling support first layer

Bed adhesion is a problem with PLA and the powder-coated / textured sheet. Sometimes, but not always, a soap and hot water wash can help.

Alcohol doesn't work as well as it can - you really need to use lots of alcohol and absolutely clean rags. Ounces, not grams. That's why dish detergent and a sink with hot water works better.

The textured sheet also needs to be baked dry after soap and water: heat on the bed at 80c for 15 minutes.

If this doesn't help, then contact support via chat and lodge a complaint. Ask for a smooth sheet as comp. It may or may not work. Most folk who have this issue use the textured for PET or TPU or ABS and avoid using it with PLA at all costs.

RE: Curling support first layer

@tim-m30

I have washed the sheet with soap but I'll give it another go based on your suggestion and report back. Thanks

RE: Curling support first layer

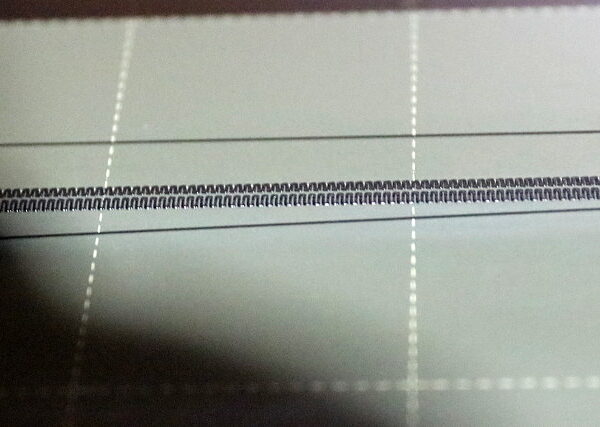

Good - with regard to the gap/no-gap issue. Are you using the 7x7 bed level? If not, know that the 3x3 sometimes misses low spots in the bed that the 7x7 finds. Just better coverage. I use 7x7 with 5 measurements per position:

G80 N7 R5; mesh bed leveling

RE: Curling support first layer

I'll make another shameless plug for what I use in this case.

It looks like you have issues getting the first layer on some PLA prints that need small footprint supports to stick, even though the plate is indeed clean.

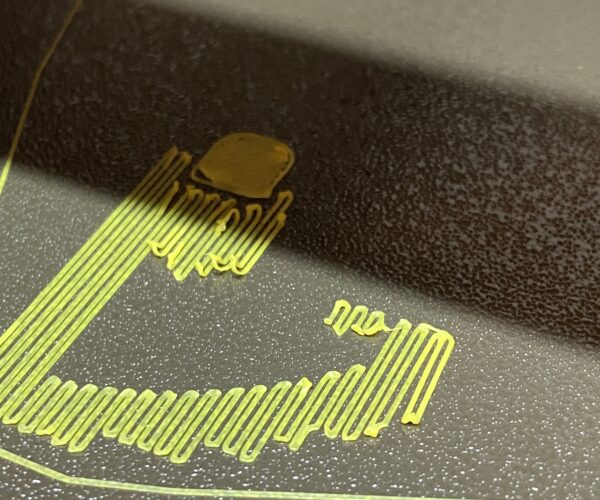

I've had this very issue, and the best solution I've found is the Layerneer Bed Weld, pictured below.

It really helps with PLA adhesion, particularly with the textured sheet.

I'm also attaching a photo of some very fine first-layer PLA supports using the product, although this time on the smooth sheet.

This product is not an alternative to cleaning the sheet, but REALLY helps with PLA adhesion, particularly on the textured sheet.

I will often times proactively use a dab of it where the corners of large flat PLA (and ABS) pieces will land, as it prevents the very frustrating warping and curl-up which can waste time and filament.

RE: Curling support first layer

@jsw

If the PEI sheet is clean (with the exception of the unique Prusa powder coated PEI sheet) PLA will stick quite well. No additives needed. In 99,9% of cases where folk have had adhesion issues with PEI & PLA, soap and water - done right - fixes it. Again, the textured sheet from Prusa is an exception: they have a process problem - some sheets are just bad - and that is why people are buying textured sheets from others and not reporting adhesion issues.

And, it's been my experience that people new to printing refuse to admit to themselves a fingerprint is a bad thing. So keeping the bed clean is a hard learned lesson that appears to take some longer to learn than others. Heck, some have even resorted to sanding the PEI sheet to help adhesion rather than maintain a clean sheet. Go figure.

ps: And here is a note from the manufacturer:

BED WELD was designed for applying directly to glass based printer beds.

RE: Curling support first layer

So I followed @tim-m30 's suggestion and re-cleaned the sheet with warm water and soap followed by baking for 15 mins on the bed....same result.

I've been 3d printing for about a year now so I'm not a complete noob so I have catered for the basics of fingerprints, oil etc. As per @jsw 's comments, the sheet has never really been a problem with printing PLA, the majority of my prints have been PLA based but I've only recently started having this problem with is making me second guess my height settings etc.

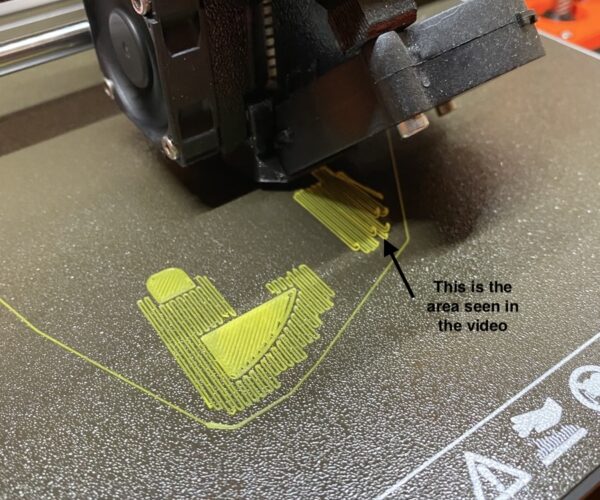

I've attached a video below of the printing in action. To my eyes, the filament seems to curl the second it comes out of the nozzle and the biggest lift points seem to be when the head changes direction. Adhesions looks reasonable until a change in direction happens (especially a 180 change in direction). In the attached photo you can see that I have (I think) a good squish of filament for the first part of the print but then it just goes off the rails.

(note: I'm not sure this forums Wordpress installation is setup for video so fingers crossed the player works - worst case the url of the video is here https://forum.prusa3d.com/wp-content/uploads/2020/10/IMG_0732.mp4

RE: Curling support first layer

We may have to agree to disagree on some things, Tim.

I'm an adult. I know when something is clean and when it is not. I've had clean-room experience in my career, working on things like hi-vac ion pumps for mass spectrometers and such. My experience is that even with a perfectly clean sheet, some PLA filaments may not properly adhere to the Prusa smooth or textured sheet without some help, particularly when small-footprint parts and thin support bases are involved.

It seems like the universal answer from some to those reporting adhesion problems is that the sheet is not clean. I would grant that in most cases that is probably true, and yes, a stray fingerprint can kill a print, but in some cases it is not. I think that it's a disservice to those who are having trouble climbing the learning curve to insist that the sheet is not clean, without considering other factors such as Z calibration, temperature issues, filament viscosity issues, and even bad filament.

Yes, Layerneer is stated to be intended for glass plates, but for me, and for others here, it works fine on the Prusa PEI plates. What works best for me may not work best for you, and if everyone always did everything the same way, this world would be an incredibly boring place. 😉 I will reiterate that Layerneer is to be used in addition to, not in place of thoroughly cleaning the plate.

I'm not trying to start a fight, Tim, but I'm just pointing out that the knee-jerk response of a plate being dirty is not the universal solution to every report from a newbee (and from a veteran) that filament will not stick.

Then there's the subject of what to clean it with, and some swear by water-based solvents and others swear by organic solvents. I think that the point needs to be made that the world will not end if you use one over the other, but that the idea is to have that plate Really Most Sincerely Clean, whatever agent is used. (As an aside, one of the ladies in a class I took a couple years ago at our local makerspace used drug-store witch-hazel solution to clean the glass plate and swore by it.)

End of rant! Now we can get back to arguing whether the grease that comes with the bearings will work or not. 😉

RE: Curling support first layer

@mortocks

The video isn't working. Sound only at my end.

Unfortunately you seem to have one of the bad powder coated sheets. Though the fact it has worked well in the past and just started doing this, hints the sheet itself isn't the problem. Beyond cleaning, the smooth sheets benefit from an acetone scrub once in a while to remove PEI oxides that build up over time. I pour a 50 mm puddle in the middle of my sheet and scrub with a fresh paper towel; this usually churns up a whitish film that I then wash off with another soap and water session.

I use very hot water when cleaning my print sheets - hotter than my fingers really like. I scrub with only a fresh paper towel - no dish rags, no sponges, nothing that has touched anything else. I rinse in the hottest water my sink can provide, and I only handle the sheet by the edges until water sheets off the surface. Generally only a few drops need to be dabbed up with a new paper towel and the sheet placed back on the printer.

I also presume you've tried a different filament spool, not just the one. Over the past couple years I have had exactly one bad spool: and it was only bad through the top few layers of filament. My guess is the person wrapping it up at the factory hand used hand lotion and fouled those top layers when putting the spool into the vacuum bag.

That said - even Prusa says the sheets are disposable consumable parts of printing: they wear out, so flip sides, and if both sides are dead, buy a new sheet. Seems harsh, but that's what they say.

@jsw is hocking a dab on adhesive - a liquid glue stick or sorts - I can't speak for that stuff - it is sold for use on glass, not PEI; but he says he has used it with good effect. I'd probably use the money and buy a third party textured sheet that others had used and recommend for PLA.

RE: Curling support first layer

@jsw

I generally don't jump to dirty beds unless I see something make makes me leap that direction. Extrusion that looks well calibrated yet pulling off the sheet as in this case - roiling up at the extreme edges or being pulled off by the second layer - is a prime example of oils or other surfactants on the sheet. Most of the cases of the PC sheet failing with PLA seem to be the part falling off after several layers are down - not an obvious layer 1 fail as mortocs is seeing; and that the sheet has worked in the past... well, contaminants are still top of mind.

As for solvent versus surfactant: I'll pick a surfactant every day. Well, unless I have access to a Freon vapor degreaser. Why is soap and water best, in my opinion? I can use 10 gallons of hot water and not feel bad about it. If I am cleaning off 100 ug of oil based fingerprints, how much alcohol would I need to use to dilute the oil to what 5 gallons of soap and water dilute it to (a couple minutes under a sink tap)? Yep, gallons. Now who in their right mind would use a couple gallons of alcohol to clean a print sheet? Yet that is what it would take to get an equal clean.

And I am not here to fight - if sanding the bed works for you - okay. If a $25 bottle of glue works for you - okay. If soap and water works for you - okay. Or, as many have done, a $30 textured sheet from company XYZ works, too. I'm also not selling anything here.

RE: Curling support first layer

Thank you all for your input. I believe I've solved the issue with the problem coming out of left field.

I noticed that there was some twisting in the bed when it changed direction. I removed the bed and tightened all the screws including the u bolts under the plate. After a quick recalibration, the issue seems to be resoled. It seems that there was enough movement as the printer changed the Y direction that moved the plate just enough to cause the filament to come away from the bed.

@tim-m30, do you have any information about "the bad powder coated sheets"? I don't think that's the issue here but something I'd like to watch out for. Did some googling but didn't find any results.

RE: Curling support first layer

There are literally dozen of threads on this forum regarding the powder coated sheets not working well with PLA.

Search the forum for "pla doesn't stick to textured sheet" and you'll see a few. I got five pages worth.

RE: Curling support first layer

Mortocks, out of curiosity, what is the code in the upper right corner of your textured sheet?

Mine is WA-15 and I apparently got one of the 'good' ones.

When I need another I will probably go third party due to the reports here and elsewhere of the crap-shoot of getting good/bad ones directly from Prusa.

RE: Curling support first layer

@jsw BH-25 so ¯\_(ツ)_/¯

😀

RE: Curling support first layer

Thanks. Another question. When did you order that BH one? All of my sheets are WA, and all were purchased in 2020, and I would like to get one more but I'm leery of getting a bad one. If the BH was purchased after I got mine, I'll probably pass.

RE: Curling support first layer

@mortocks

I have the same BH-25 and have no problem with the powder coated sheet printing PLA, PETG (botbh Prusament) and NinjaFlex

Having problems with bed adhesion every morning...

RE: Curling support first layer

Been printing for a couple of weeks without issues (MK3S) but the first time I had to use support extensively I ended up with the exact same issue!

I've been using IPA 99% to clean my Prusa powder coated sheet all that time and it was working great until I tried to print with lots of supports on the first layer.

Never tried to clean the sheet with hot water and soap (using Dawn) and to my surprise it worked!!!

I'm now printing those supports perfectly and they all stick nicely to the sheet.

Thkx for the tips! 🙂