Constant clogging

Hello -

I have had an MK3 printer for just over a month now, and have had several successful prints with the .4 nozzle. Recently, I picked up the E3D "Fun Pack", and tried the .3 nozzle out.

Things were going just fine with the new nozzle, and I had several successful prints. The other day, however, the nozzle clogged during an 8-hour print for some reason, and I have not been able to get a successful print since then. The nozzle just keeps clogging at different points during each print I try, and there doesn't seem to be any sort of consistency as to when it happens (even on the same print).

I've been using 1.75mm PLA, and I have tried adjusting the tension screws, playing with different nozzle temperatures (200-220 C), adjusting the Z height through the first layer calibration wizard, cleaning the nozzle, removing the nozzle and clearing out the heater block, but to no avail.

Just prior to the clog, I had successfully done an 11-hour print, immediately followed by a 2-hour print without any issues. I let the printer sit for a bit, and then kicked off an 8-hour overnight print, which is the one that failed.

After letting the printer sit for a couple of days, I tried again today, but still no luck.

In an attempt to rule out different components, I tried swapping out the nozzle with the .8 mm nozzle from the pack, and was going to try a larger, less-detailed print.

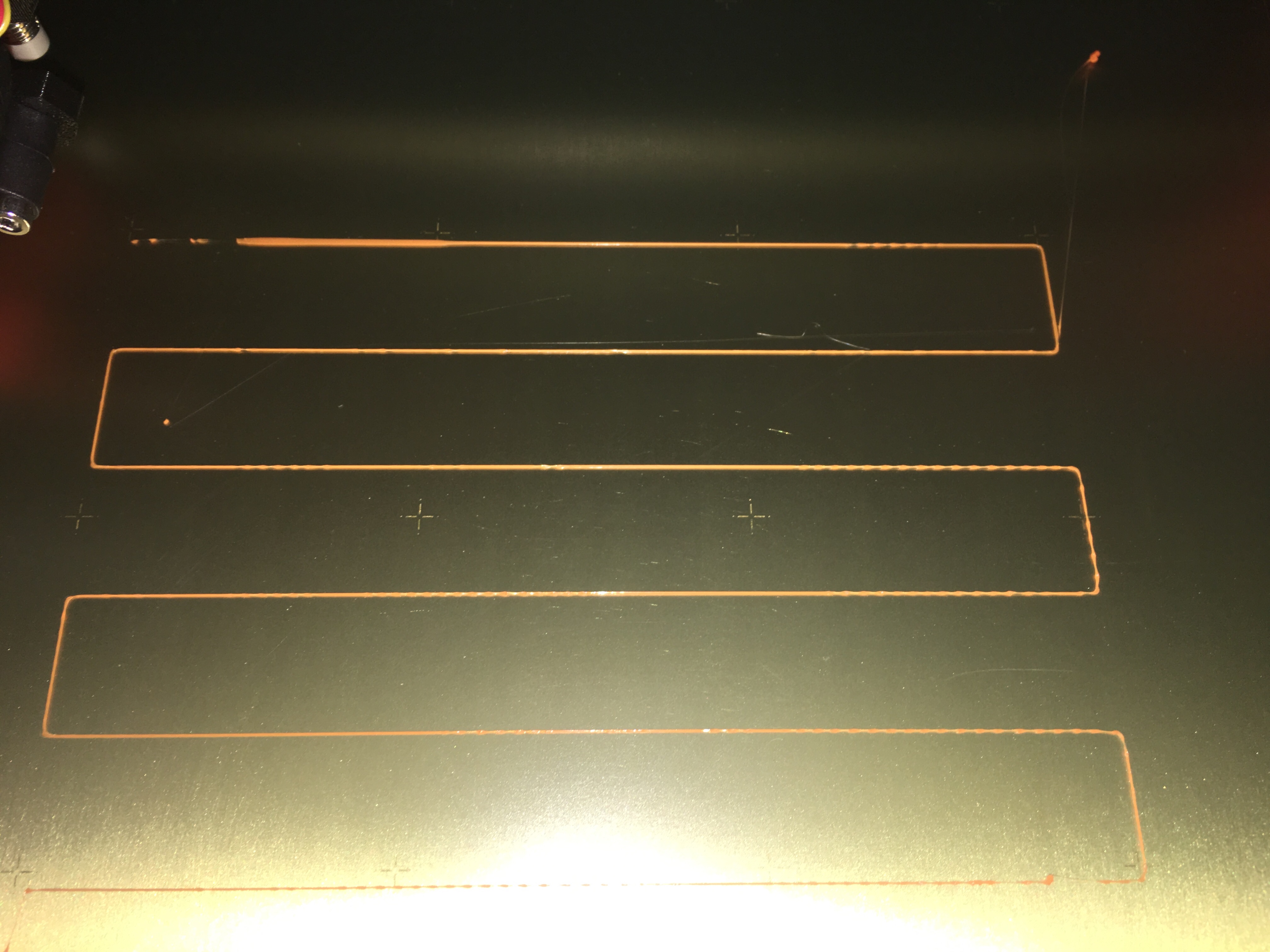

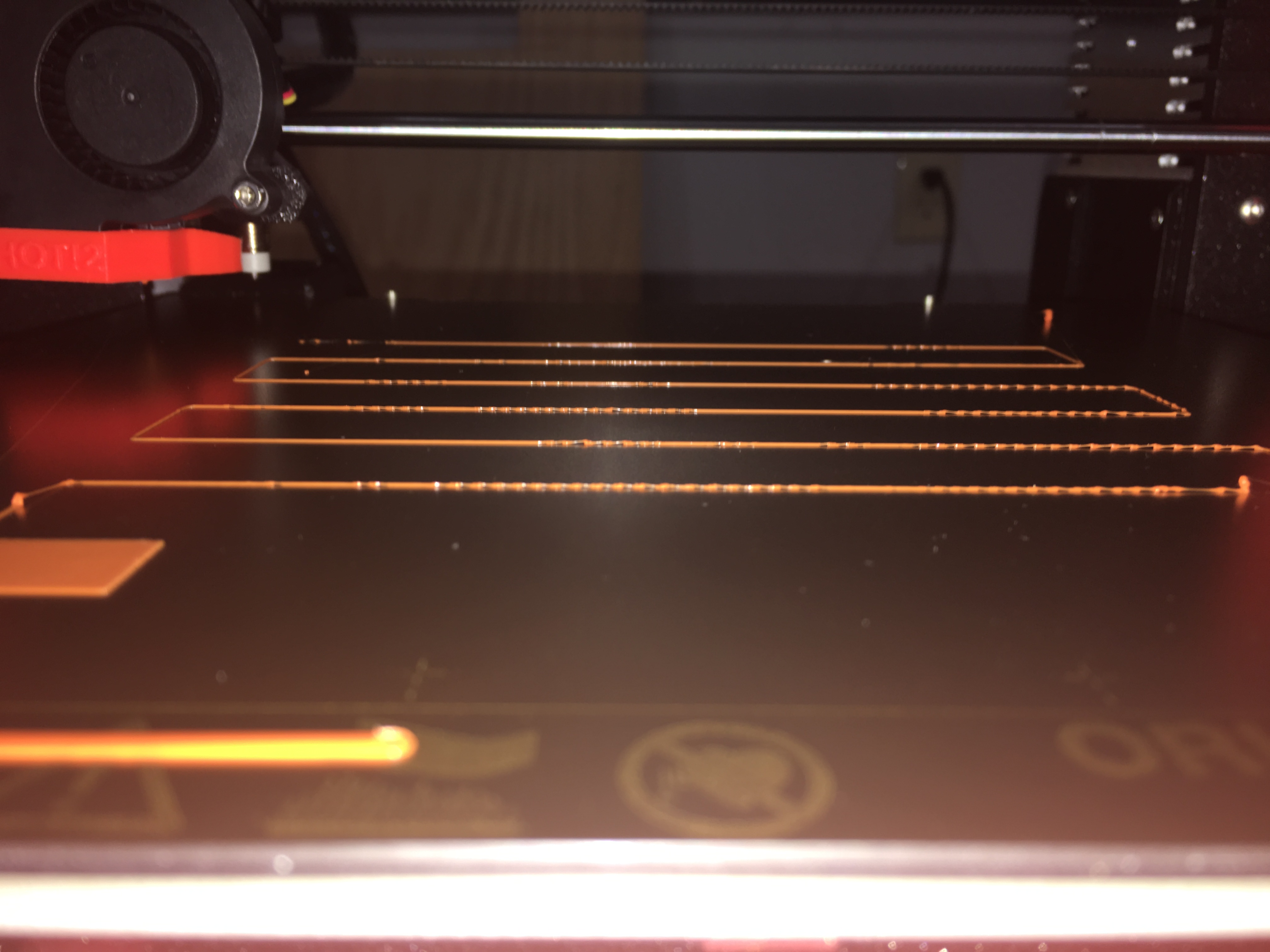

I couldn't even make it through the first layer calibration without running into any issues, though, so I never even got to try the print:

It almost seems like there is some sort of temperature/heating issue, because as the printer was doing the 9-point calibration, the filament seemed to get clogged, as the quick priming line that's always printed at the base of the sheet was only half-printed. Being new to the 3D printing world, however, I'm not sure what it would be, and would hate to just start randomly replacing parts in a "guess and check" fashion.

Any thoughts/help would be greatly appreciated.

Thanks,

Tony

Re: Constant clogging

there may be something inside the hotend above the block causing drag or a partial jam. I'd make sure the throat of the heatsink is clear and that the ptfe tube is seated properly. take a look at the top of the tube just below the extruder gears and see if its mangled or misaligned. clean out the extruder teeth and make sure the idler is aligned and lubed.

good opportunity to add a collet clip to the bowden coupler to keep the tube from moving around as well. https://e3d-online.com/collet-clips

Re: Constant clogging

Thanks for the response. I'll dig further into the hotend to see if there's anything else that needs cleaned out. I didn't take it that far last time.

I did clean out the extruder teeth a bit already, but will give that another look, and I'll also check out that collet clip you mentioned.

Thanks again for all the info! Hopefully, this will get me printing again.

Re: Constant clogging

Did you make all the necessary setting changes when you changed the nozzle size?

Are you using the same filament as the successful print? If not, you may need to change the temperature.

Check the grub gear - is it clean?

- 1st "printer" TIKO 3D

- 2nd PRUSA i3 MK2S with MMU v1

- 3rd PRUSA i3 MK2S

- 4th PRUSA i3 MK3 with MMU v2- 5th PRUSA i3 MK4 (upgraded from MK3) with MMU v3 (upgraded from…

Re: Constant clogging

[...] In an attempt to rule out different components, I tried swapping out the nozzle with the .8 mm nozzle from the pack, and was going to try a larger, less-detailed print.

I couldn't even make it through the first layer calibration without running into any issues, though, so I never even got to try the printOh wait... Did you try running the on-board 1st layer calibration with the 0.80mm nozzle? That's not going to work. Unless I'm gravely mistaken, that routine is set for a 0.40mm nozzle. What you want to do is create some 1st layer calibration pieces for each of your nozzle sizes.

I recommend the following:

If, and only if, you can rub a finger over a 1st layer bead and have it stay put, proceed. Otherwise, you're wasting your time.

As to why it clogged with 0.30mm, what slicer were you using? In general, if you get into clogging issues, slow down. Slow way down. Start printing one of the prints that won't complete, and dial speed down to 50% using the front knob. If that works, you know it's not a hardware issue and you can tune your slicer settings. If that still fails, try another filament or slightly higher temps.

Beware of excessive retractions, particularly as you get to the tips of pointy bits where the printer spends a lot of time on small parts. Excessive retractions generate heat, which can lead to all sorts of problems. Cranking retraction up is not a good idea in these circumstances. Better to print with a bit of string and use a heat gun for a quick clean-up.

If your 0.30mm nozzle is the culprit, I'd suggest doing some cold pulls using cleaning filament heated to 250C, extruded a bit, then allowed to cool. That should get any crud out of the nozzle.

I've had good luck printing with 0.25, 0.30, 0.40, 0.50, 0.60 and 0.80mm nozzles, using strictly PLA on the smaller sizes and a hardened steel 0.40mm+ nozzle for any filled materials.

Let me know if you need STL models to slice, or even pre-generated gcodes for a quick test. I can test them and share my slicer (Slic3rPE preferred) with you.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Constant clogging

Thank you all for the great info!

As far as I know, I changed all of the necessary print settings with the nozzle change, and I made sure to clean the grub gear, as well.

I've been using the same PLA (MatterHackers Build Series PLA), and I'm wondering if that's actually the culprit, so I'm going to try switching to the Prusa filament that came with my printer when I get a chance.

Thinking that there was something wrong with the .8 nozzle (didn't see the responses before evaluating this, of course), I switched to the .35mm nozzle in the same pack, as I have more prints with more detail that a smaller diameter would handle better.

The same thing happened, though, that I ran into with the .30mm nozzle - I was able to get about 5 or 6 successful prints (exact same print each time @ about 1.5 hours apiece), and then it just randomly started clogging again. I didn't change any settings at all between prints, as I didn't figure I needed to.

It's almost like the nozzles are just building up gunk over a handful of prints, and then the opening is maybe too narrow to cleanly pass the filament through, which then starts sticking to the sides of the nozzle and clogging up mid-print.

Being that I already had the .30mm nozzle removed before posting, I didn't do any cold pulls with that one, but did a few with the .35mm nozzle last night. I just haven't had a chance to see if it's made any difference, though.

Is this common for a nozzle to get gunked up so quickly? This is why I'm thinking it's the quality of the filament and not necessarily other factors, but I don't know. Only getting 5 or so small(ish) prints through successfully before constant clogging just seems way too frequent to me, but being new to this hobby, maybe my expectations are too high?

I've kept the retraction settings close to the default settings for the last couple of weeks, as I ran into major clogging early on when I jacked these settings up quite a bit. I realized quickly what sort of impact these settings had and have since left them alone (for the most part).

Thank you for the info on the 1st layer calibration, too, regarding how it was created with a .4mm nozzle in mind. That explains a lot 🙂 I guess I just assumed the wizard in the printer's calibration menu was more of a "one size fits all" approach.

Thank you, as well, for the info on using various models to do the calibration. I will be sure to snag the model you referenced and use that, along with the other ideas you listed, moving forward!

And to answer the Slicer question - I've been using Simplify3D as of late, but thought about running my models through the Slic3r PE software I started with to see if that makes any difference. I've just heard really good things about Simplify from so many people, so I thought it'd be worth jumping onto that ship early on, but I think I may have gotten in way over my head too early, as it's been a little overwhelming to learn what the many different settings do. 😐

Re: Constant clogging

Jams should be infrequent. Hot temps certainly contribute, but it shouldn't be a daily or even weekly thing once you learn the basics. You're in "rapid learning" (firehose) mode, so be sure to learn the individual steps one at a time. I got in trouble trying to jump in with too much at once.

[...] Is this common for a nozzle to get gunked up so quickly? This is why I'm thinking it's the quality of the filament and not necessarily other factors, but I don't know. Only getting 5 or so small(ish) prints through successfully before constant clogging just seems way too frequent to me, but being new to this hobby, maybe my expectations are too high?

I've kept the retraction settings close to the default settings for the last couple of weeks, as I ran into major clogging early on when I jacked these settings up quite a bit. I realized quickly what sort of impact these settings had and have since left them alone (for the most part).

Unfortunately, a lot of tricks can cause problems if you go overboard. You read up on using retraction to reduce stinging, and you wind up with things cranked up too far. Those retractions cause a lot of filament to be pushed and pulled by the extruder. That can pull up molten filament, or at least cause the extruder motor to heat up. I see a lot of posts by people having problems as prints near the finish with pointy or fine details. Those can have a lot of rapid retractions due to the small layers which can compound things. Add in an enclosure or a hot summer day, and you can definitely exceed a threshold.

Most things should work reasonably well with PrusaControl or Slic3r. Have a simple part saved off as gcode that you can print if everything seems to be falling apart. If it still works, you know you've got settings issues. When I get stuck, I print out a little 20mm cube I saved off.

Thank you for the info on the 1st layer calibration, too, regarding how it was created with a .4mm nozzle in mind. That explains a lot 🙂 I guess I just assumed the wizard in the printer's calibration menu was more of a "one size fits all" approach.

It took me a bit to realize that saving off calibration prints as gcode files for each nozzle size was a really good idea. I've got a 1st layer calibration, 1st layer torture test and a 20mm cube saved off for each nozzle size in several different filaments.

[...] And to answer the Slicer question - I've been using Simplify3D as of late, but thought about running my models through the Slic3r PE software I started with to see if that makes any difference. I've just heard really good things about Simplify from so many people, so I thought it'd be worth jumping onto that ship early on, but I think I may have gotten in way over my head too early, as it's been a little overwhelming to learn what the many different settings do. 😐

I started with Simplify 3D. The slicer is fast, and the flexible supports are fantastic. Unfortunately, it makes some things unnecessarily hard. Be aware that the Prusa settings for S3D are a bit too aggressive on speeds. There are a lot of "tweaks" done by various experts. They're very good, but a lot of the differences come down to the custom gcode they're using, not necessarily the obvious settings you can tweak in the interface. Speeds are a real PITA with S3D, and that's my biggest gripe. In general, keep speeds slow until it works, then speed things up.

I would recommend at least having Slic3rPE handy just to have a "known good" starting point as you learn. If you get in a jam, try the same part in Slic3rPE, even if it's not ideal. The maximum extrusion speed settings have been really important for me in eliminating extruder skips & jams. As I figure things out in Slic3r, I can reverse-engineer the settings into S3D and other slicers.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Constant clogging

The maximum extrusion speed settings have been really important for me in eliminating extruder skips & jams. As I figure things out in Slic3r, I can reverse-engineer the settings into S3D and other slicers.

What Retraction Settings in Slic3r PE are you using for PLA (still using inventory of Printrbot PLA), Normal Quality?

What specific extrusion speed setting in Slic3r PE are you using?

Thanks

Southridge High School has three MK3 and one MK2S.

Two of the MK3 are experiencing jams and we have not been able to isolate the issue.

Richard

Re: Constant clogging

Have you tried using a "Flossing" filament (like this: https://rigid.ink/products/floss-superior-cleaning-filament )? I use it and it does help.

Avoiding clogs seems to come down to using good quality filament and getting the 'sweet spot' temperature for that filament.