RE: Complete frustration with MK3 - first layer/print problems and it's about to become a boat anchor

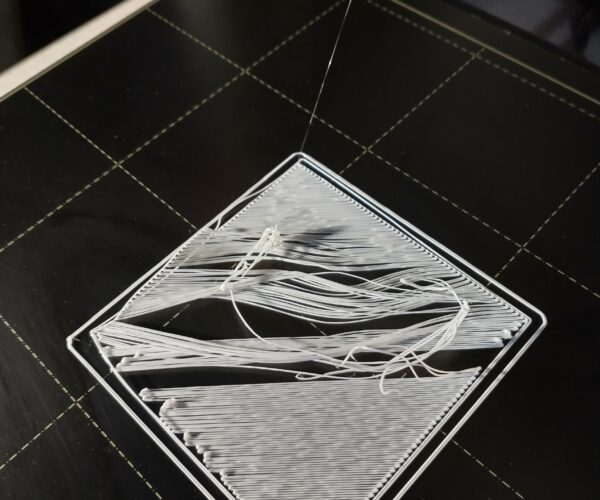

Looking at the support base pictured the live z is still no where near low enough.

RE: Complete frustration with MK3 - first layer/print problems and it's about to become a boat anchor

I don't get how youres is so good the best I could ever get was smooth but not like that

Please help me out by downloading a model it's free and easy but really helps me out https://www.printables.com/@Hello_474427/models

RE: Complete frustration with MK3 - first layer/print problems and it's about to become a boat anchor

I'm currently running another first layer calibration print and brought it down to -0.545 and it's looking near solid. We'll call my last picture there a flesh wound. 😉

RE: Complete frustration with MK3 - first layer/print problems and it's about to become a boat anchor

It’s just practice 😊and knowing what my printer is capable of.

RE: Complete frustration with MK3 - first layer/print problems and it's about to become a boat anchor

@Joantabb that is the same file that I use for my first layer calibration, but I am curious as to why the gcode file is set higher temp for PLA than we normally print at and the heat bed is lower. PLA as you know is 215/60 default. The gcode on that file is 225/55. If we are supposed to compare apples to apples here, why is it a different heat setting? Doesn't this skew our results a little bit here?

At any rate, posting my first layer cal. here. I am at -0.170 with this entire first layer, and appears it needs to be dropped some more. Forgot to mention that I have a digital caliper and this layer measures at .3mm.

the temperatures for various filaments are not set in stone. and your printer doesn't actually know what temperature the extruder or heat bed are actually achieving, the sensors (thermistors) send back a value that the einsy board interprets with the help of a table of values, to approximate a particular value.

I recently had a situation where

There are no obvious 'Apples' to compare to 'apples' this is why we have temperature towers and similar things...

even different colours or batches of the same manufacturers filament can have different characteristics.

I often use 70C for the bed temperature for PLA.

One roll of white PLA, Was perpetually stringing, and I ended up having to lower the 'low temperature extrusion' limit from 170C to 140C, so that I could then lower the extrusion temperature to 170C.

also, speed of printing, can cause a need for different printing temperatures. faster printing may need higher extruder temperatures.

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Complete frustration with MK3 - first layer/print problems and it's about to become a boat anchor

More often than not, I've found that the default temperature for almost all true PLA filaments is the best to use, unless the manufacturer of the filament recommends something else.

One exception is the Mika3d metallic filaments, and for those, I've found that sometimes they will jam in the extruder unless the temperature is goosed 5-10 degrees or so.

Now if there are any adjectives surrounding 'PLA' in the descriptions, sometimes it's a whole different situation. 'Tough PLA', 'PLA Pro', etc. may require something higher or lower.

Even the slicer defaults can be different. PS is usually 215 or so, but Cura (at least with the profiles I have loaded) is usually 205 for PLA.

RE: Complete frustration with MK3 - first layer/print problems and it's about to become a boat anchor

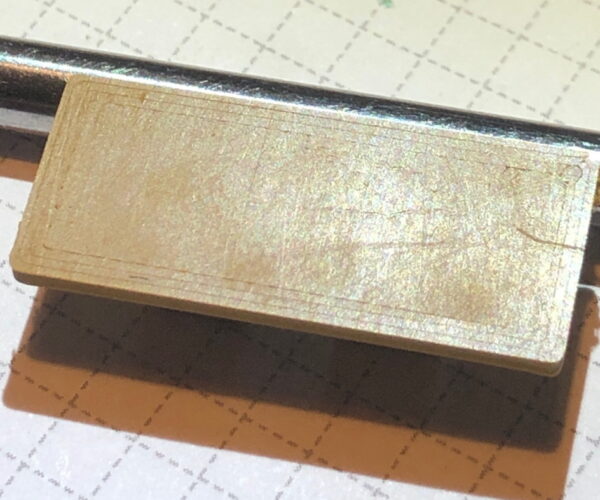

Thanks for the clarification. So it appears that I am down to just the fine tuning of the layer. I am at -0.630 and it is a big difference than from earlier today. I printed the same figurine, but I did slow down the printing a bit (.STL file from HeroForge) because of it also being a small print. The bottom of it has significantly improved from the first print.

RE: Complete frustration with MK3 - first layer/print problems and it's about to become a boat anchor

Well, bummer. Here I was hoping to pick up a cheap "boat anchor" Mk3S+ for scrap price.

RE:

My MK3S+ was at z level -1.800 and I was happy with the first layer here.

You can still go a lot more with your printer - looking at your white print I'd still go further.

Basically when you look from underneath the print you shouldn't be able to see hardly any lines - mine used to be perfectly flat (I say 'used to' because I sold the unit while I want for the MK4 kit). With your white print the lines are still quite clearly visible. Don't be scared to lower further. I'd say you can still go another good -0.2 more then what you're currently on.

RE: Complete frustration with MK3 - first layer/print problems and it's about to become a boat anchor

That is pretty close. If the lines are not fully fused, you did not go low enough.

Thanks for the clarification. So it appears that I am down to just the fine tuning of the layer. I am at -0.630 and it is a big difference than from earlier today. I printed the same figurine, but I did slow down the printing a bit (.STL file from HeroForge) because of it also being a small print. The bottom of it has significantly improved from the first print.

--------------------

Chuck H

3D Printer Review Blog

RE: Complete frustration with MK3 - first layer/print problems and it's about to become a boat anchor

Shawn, as others have said, it is a process of adjustments until you get it right for the filament and from what I have found out, local environmental conditions. Today, after a month of trying, I feel I have my first successful PETG print. When I dreamed (4 months ago) about 3D printing, I thought it was going to be easy. Prusa was suggested to me by a work associate. After 2 months of using the printer, I still feel it was the best choice.

From work, I have seen so many failures in 3D printing, even after years of usage. There is so much more to learn. To make me feel more scared, I look at all the various setting in the slicer software, to understand that there is so much more to learn. As a technologist, that is part of the challenge. As a user, it is a headache. On the other hand, I find that I can now 3D print something that I need, much quicker than going out and trying to find it in a store, if I can find it.

People on this forum have made me feel normal, and have helped me, even before I purchased my printer. My situation is different than theirs, and yours, and their advice is related to their experiences and their environment. There have been links I have found over the months that are like text books on 3D printing. There are many things to try and configure.

I have stuck with Prusa filament to start with. It is a standard due to the printer, but I have found that doing the various calibration tests, found on the Prusa knowledge base and on this forum, I have issues. Doing one calibration, comes up with different numbers than other ones. Some calibrations affect other calibrations. An example, change extruder rate, that changes the z calibration. Change nozzle, even to the same size and brand, has a small effect on the extrusion rate. From what I have read, even different spools of the same filament may affect the print quality. I have not experienced that, yet. This doesn't even get into the situation of how dry the filament is.

As I have said before, in other posts, I have seen failures from expensive commercial printers that promise easy prints. Of course, unlike Prusa, and the forums, it costs money to get any support. A web search can find so many links on how to configure and set up your Prusa printer and there is no cost to do that. A web search will also show you that there are so many options to each and every print process, it can be overwhelming.

And keep working on the process to ensure that Netpackrat doesn't get a good deal on a 3D printer. 🙂

From the images, you age getting progress and that is the goal. I have a notebook, just for 3D printing notes, and there is something written in it, every time I run the printer or I read something that affects printing.

RE: Complete frustration with MK3 - first layer/print problems and it's about to become a boat anchor

Thanks to everyone (who was constructive) with helping out here, my printer is working fantastic. What I thought was flat enough was obviously not and I did have a slight bed level correction to do after firing up Octoprint.

I have a new issue, more hardware but curious which I will make a new post about re: ABS.

Thanks again.

RE: Complete frustration with MK3 - first layer/print problems and it's about to become a boat anchor

If you planning to print with ABS, I would not do that until you get good printing with PLA and PETG. ABS will definitely require more skill and an enclosure.

--------------------

Chuck H

3D Printer Review Blog

RE: Complete frustration with MK3 - first layer/print problems and it's about to become a boat anchor

I actually just finished printing three ABS items with no troubles, as I said my printer is working just fine now.

The only problem I have that I touched on is that after printing that ABS, it actually warped the hell out of my sheet. I have to get a new sheet because of it as it made humps on top of the sheet.

RE: Complete frustration with MK3 - first layer/print problems and it's about to become a boat anchor

What sheet do you have ideally you need textured one

Please help me out by downloading a model it's free and easy but really helps me out https://www.printables.com/@Hello_474427/models

RE:

The original sheet that came with the printer (smooth) and luckily, I had very little shrinkage with it. I also only used the ABS settings for temps on the printer.

RE: Complete frustration with MK3 - first layer/print problems and it's about to become a boat anchor

Contact prusa support though live chat let them know

Please help me out by downloading a model it's free and easy but really helps me out https://www.printables.com/@Hello_474427/models