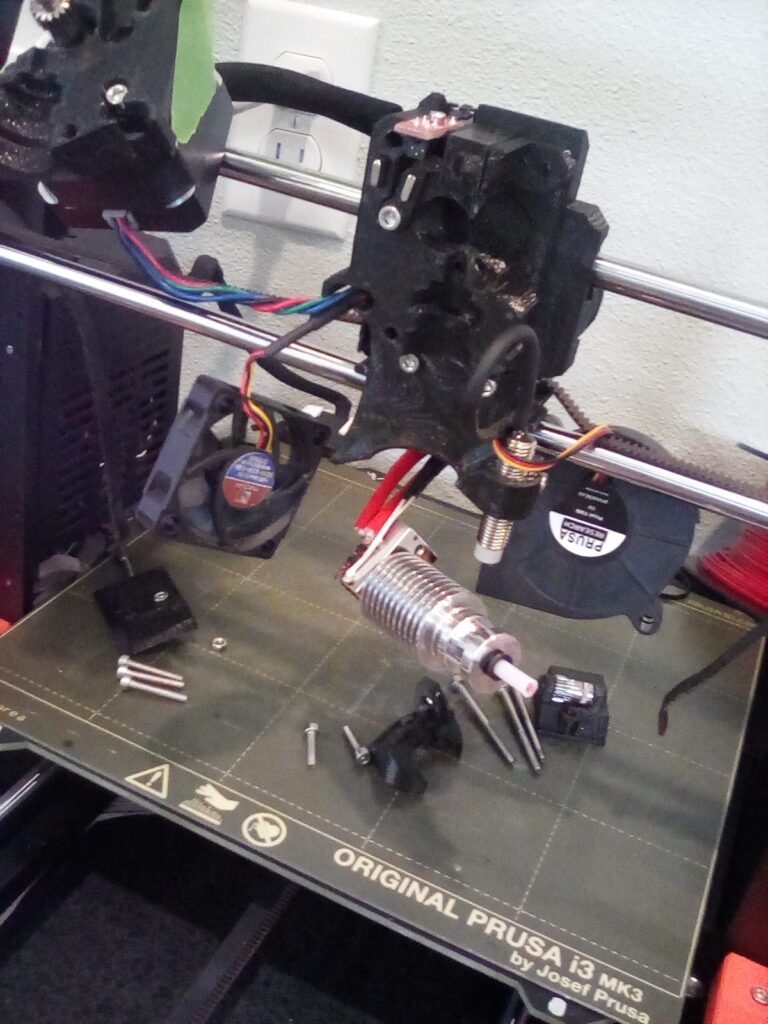

Clogged nozzle fix gone wrong; help needed

So I messed up big time. Long story short, I had an ABS print go overnight, where it clogged and kept trying to print for 3 more hours. I tried to heat it up to temperature, disengage tension, then pull. However, the filament snapped before it released (landing me in my current situation) . I disassembled the extruder to clean the drive gears (they were caked in ABS dust) and get better purchase on the filament but that was unsuccessful. I got out some tweezers and heated the extruder, but they broke the filament more, rather than extract it.

What would you recommend I do? Should

RE: Clogged nozzle fix gone wrong; help needed

Pull up the black locking collar about 1.5 mm to release PETF tubing.

Remove the PTFE. It will come straight out once locking collar is clicked up.

If filament is still stuck, set nozzle temp to about 250C. As nozzle heats up, pull with moderate tension up on filament. It will release once melt temp is achieved. Immediately turn off nozzle heating.

Reassemble hot end. Heat back up to ABS melt temp. Run at least 20 cm of cleaning filament through to clear out nozzle. If no cleaning filament is available use some other filament. Idea is to run a fair amount of filament through hot end and nozzle while nozzle is at ABS melt temp. If clogged, you may need to run a needle through nozzle, replace nozzle, or attempt a cold pull.

RE: Clogged nozzle fix gone wrong; help needed

Remove the PTFE. It will come straight out once locking collar is clicked up.

The collar clicked. More of a SNAP, really. I tried pulling out the PTFE tube anyway, but it just stretched. I guess I have to wait a month for a new hotend to ship to me.

RE: Clogged nozzle fix gone wrong; help needed

@pjkincaid

Try unscrewing the Heatsink,

With luck, the PTFE Will come out of the heatbreak as you unscrew the heatsink. if this works,

Cut the PTFE off, flush with the top of the heatsink and push the ptfe tube into the heatsink with a 3.5mm drill, (Blunt end... ) the tube should drop out of the bottom of the heatsink and the jaws of the black clip should fall out,

If this is successful, all you need is to clear the filament out of the hot end, as discussed above, and then replace the PTFE tube and the Black circlip.

4mmx2mm PTFE can be obtained from, ebay or amazon or local suppliers,

https://e3d-online.com/ptfe-bowden-tubing-100mm-1-75mm-filament

Some people prefer Capricorn PTFE

https://e3d-online.com/capricorn-bowden-tubing-100mm

the black clips can be bought from e3D Online

https://e3d-online.com/embedded-bowden-couplings-for-plastic-1-75mm-filament

If you can't cleat the heatsink

https://e3d-online.com/v6-heatsink you need the 1.75mm version

If the UK is too far away , try the resellers list

https://e3d-online.com/resellers

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Clogged nozzle fix gone wrong; help needed

@guy-k2 Update: You are supposed to push the collet, not pull. Using a tiny screw driver, i pushed on the remains of the collet and freed the tube.

RE: Clogged nozzle fix gone wrong; help needed

OMG! I definitely go that backwards. Sorry for that.

Particularly bad memory failure when I also routinely use a collar lock piece to hold that collar up.