Can't get first layer right

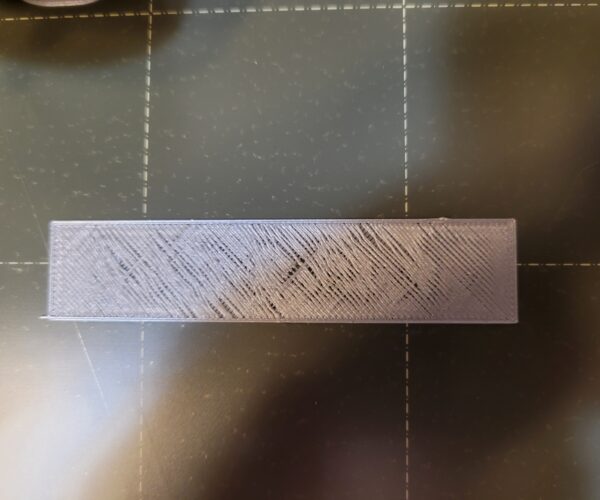

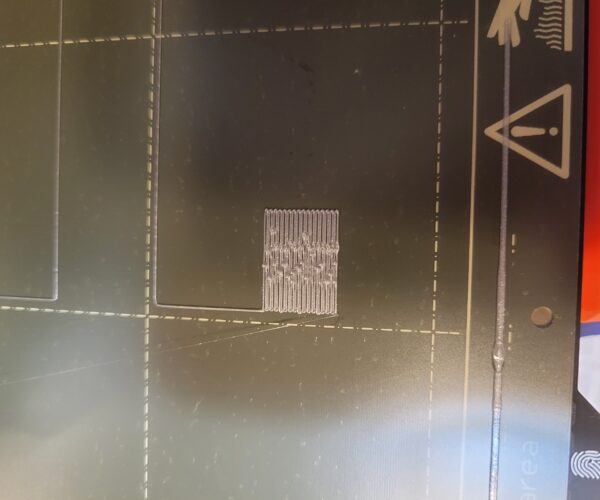

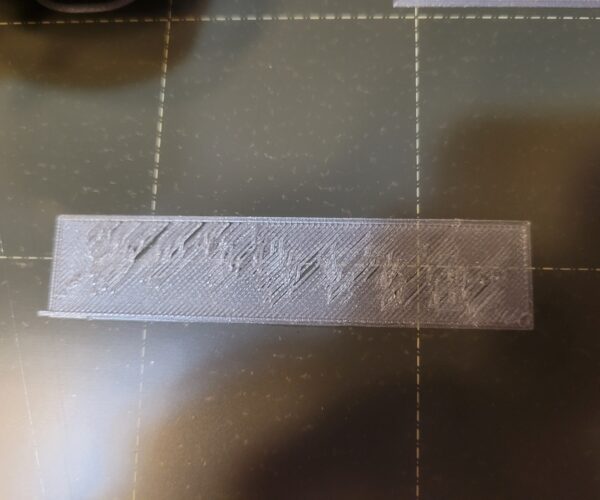

Hey! I've tried calibrating my first layer a bunch of times but no matter what setting I pick it comes out bad. What am I doing wrong here? Why are there bumps in my print?

Best Answer by --:

@veritas

You also have a drive gear problem. One or both of your gears driving the X and Y belts is loose on the shaft.

They should be fixed asap. Use the flat-first method.

- Loosen both set screws so the gear spins on the shaft.

- Align and tighten a set screw on the shaft flat, wiggling it as you tighten to ensure the flat on the set screw is flat on the shaft. Torque the screw down to spec (don't over tighten it and strip the aluminum threads or head).

- Only after the flat is set, now begin tightening the set screw on the round.

-- do not go back and retighten the screw on the flat - it gets tighter when you tighten the screw on the round and you'll end up stripping it. - Reverse the procedure when you need to maintain the belt.

RE: Can't get first layer right

Your Live-Z adjustment appears to be very high. Those lines should stick firmly to the PEI smooth sheet.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Can't get first layer right

@veritas

You also have a drive gear problem. One or both of your gears driving the X and Y belts is loose on the shaft.

They should be fixed asap. Use the flat-first method.

- Loosen both set screws so the gear spins on the shaft.

- Align and tighten a set screw on the shaft flat, wiggling it as you tighten to ensure the flat on the set screw is flat on the shaft. Torque the screw down to spec (don't over tighten it and strip the aluminum threads or head).

- Only after the flat is set, now begin tightening the set screw on the round.

-- do not go back and retighten the screw on the flat - it gets tighter when you tighten the screw on the round and you'll end up stripping it. - Reverse the procedure when you need to maintain the belt.

RE: Can't get first layer right

Thank you both! I think the main problem was the X belt drive gear was loose like you said. Once I fixed that the prints started coming out reasonably and I was properly able to set the Z-level/offset.