Cannot calibrate XYZ - always fails on finding 1st calibration point

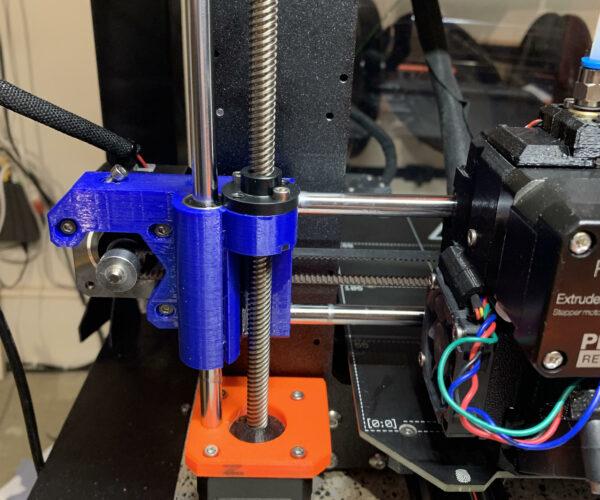

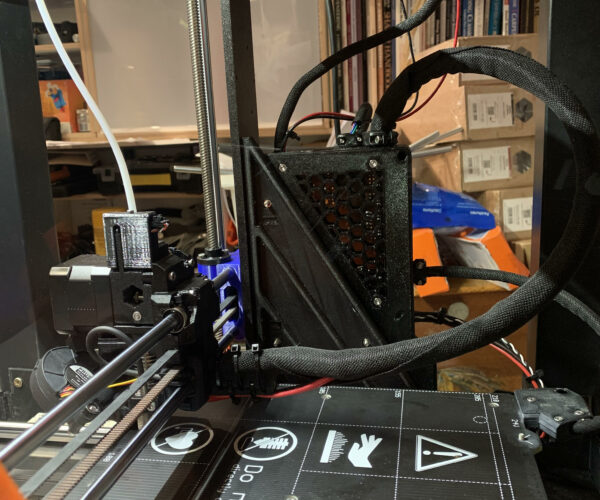

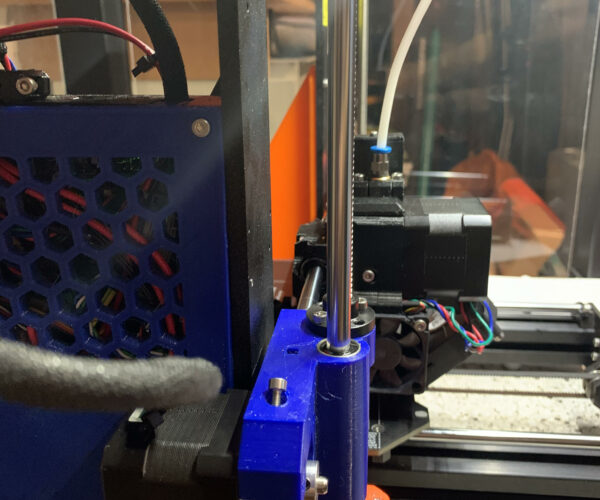

Been using MK3S for about 18 months with few issues. Installed MMU2S a few months back and had all sorts of issues. Never fully resolved but decided to make some changes such as the rails and bearings to the Misumi ones.

Took it apart and put back together - broke the x motor mount by tightening the adjuster too much! Printed new part and installed that.

Since then something is badly wrong - in first instance the belt tightness was 86 for x and 286 for y! Loosened both and after a few tweaks to belt tightening and loosening I have now got readings of x 127 and y 290. The x belt is a lot looser than I have ever had it but the reading is still way off.

When I click on Auto home - it does its dance and moves to the right a cm or so. If I keep auto homing it just keeps moving over to the right until it gets to the other side.

The home position is being stored incorrectly right from the start - if I try to move the x axis in Settings I cannot move it to the left to get to the first calibration spot.

I have read many posts and checked all the usual suspects such as cable ties bumping into things and pinda height but I cannot see what the issue is. It must be something to do with assembly but I just cannot work it out - any ideas?

Other things tried:

Removed x axis belt and ensured the extruder can move freely on the rails - it does.

Adjusted y axis belt to be a little looser/tighter

Things yet to try:

Re-install old bars and bearings - might be the best way to see if the rails/bearings have caused the issue rather than something else.

Complete strip and re-build - agh!

Best Answer by zabg:

Finally, got my Prusa working with MMU2S in single filament mode - will leave multi filament tweaking until after Covid19.

So symptoms:

Initially could not do self test as failed on X axis test

Then failed on XYZ calibration as it could not find the first calibration spot

Everytime I did an auto home the extruder would move to the right a cm or so.

Belt status was crazy tight for x axis - 86!

Cause:

X axis motor mounted the wrong way round - cable pointing up rather than down. This caused all the issues - never knew it could cause so many issues.

Once that was rectified the belt status rose to 197 - still tight but loads better. Since got it to mid 200s.

Thanks for the silence 🙂 I think the process of writing it down helped in getting to bottom of this. Hopefully this may help someone in the future.

N.B. The Misumi rails and bearings are nice and quiet - noticeably quieter than stock ones.

RE: Cannot calibrate XYZ - always fails on finding 1st calibration point

Update: Tiredness causes all sorts of stupidity to happen 🙂

Fresh this morning and found a few issues - X motor was upside down! Fixed that and tension getting back to more normal - 213 and y 288

Now dealing with Z axis wanting to break the heatbed! Keeps pushing down and then failing self test - investigating that now.

RE: Cannot calibrate XYZ - always fails on finding 1st calibration point

Doh! With all the fiddling, the nozzle had come loose and was hanging off! New nozzle and had not tightened it properly yet as did not see the point until I could get self test sorted. Doing that now......beginning to sound like a comedy of errors.

RE: Cannot calibrate XYZ - always fails on finding 1st calibration point

Finally, got my Prusa working with MMU2S in single filament mode - will leave multi filament tweaking until after Covid19.

So symptoms:

Initially could not do self test as failed on X axis test

Then failed on XYZ calibration as it could not find the first calibration spot

Everytime I did an auto home the extruder would move to the right a cm or so.

Belt status was crazy tight for x axis - 86!

Cause:

X axis motor mounted the wrong way round - cable pointing up rather than down. This caused all the issues - never knew it could cause so many issues.

Once that was rectified the belt status rose to 197 - still tight but loads better. Since got it to mid 200s.

Thanks for the silence 🙂 I think the process of writing it down helped in getting to bottom of this. Hopefully this may help someone in the future.

N.B. The Misumi rails and bearings are nice and quiet - noticeably quieter than stock ones.