Built the machine, but when I do the first layer calibration it does not stick to the bed

When I try to do my first layer caliibration the filament is not sticking.

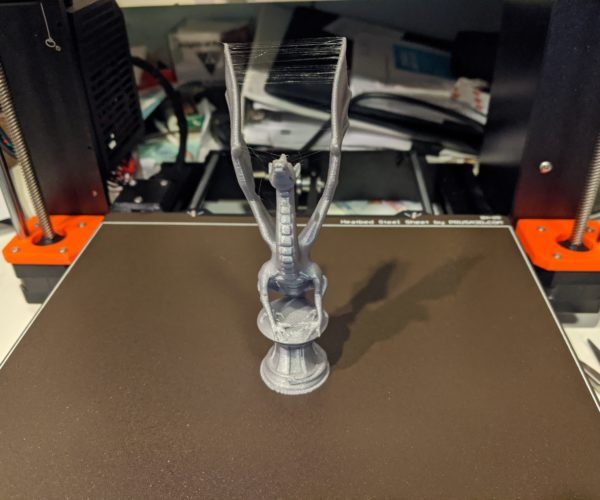

I think this is not normal extrusion at the start of the test but if I let it continue, it does not stick to the bed, and I wind up with a ball of filament sticking to the extruder. Is my head to high, or is it too low? How do I adjust it to get the first layer to print correctly?

My last printer I used a piece of paper and adjusted the bed until it was correct at all corners and middle, there are no adjustments on this.

HELP!

Thank you in advance,

Ken

RE: Built the machine, but when I do the first layer calibration it does not stick to the bed

Give the textured sheet a wipe with isopropyl alcohol and re-run the Live-Z calibration. Based on your picture, it appears your Live-Z is very high. That little wispy strand should be a solid line of filament that adheres firmly to the print surface. Lower (make more negative) your Live-Z settings. At that height, you can go down in fairly large increments (0.1mm) until you notice the filament starting to stick. Once it's correct, you should be able to nudge the strands without them coming loose. You may have to repeat the Live-Z calibration a few times to get it low enough. No worries, it's all working at this point.

Once you complete the "official" on-board Live-Z adjustment at least once, it should look something like this:

After completing the on-board routine one (required to set a flag in non-volatile storage), you will find Jeff Jordan's "Life Adjust" procedure much easier to use and understand.

Congrats on your assembly. You've almost got it going.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Built the machine, but when I do the first layer calibration it does not stick to the bed

Thank you Bobstro,

I tried that, but it made no difference, going to look at other causes, blocked extruder nozzle possibly?

Ken

RE: Built the machine, but when I do the first layer calibration it does not stick to the bed

At 7:17.

RE: Built the machine, but when I do the first layer calibration it does not stick to the bed

Hi lichtjaeger,

I did this. Going to see if something is blocking the nozzle. The bead just looks wrong.

Ken

RE: Built the machine, but when I do the first layer calibration it does not stick to the bed

It's not true that there are no adjustments here. Did you read "handbook" manual? It's all there... Did you run first layer calibration? Your head is way to high. During that calibration you must lower print head (change live Z value) accordingly.

RE: Built the machine, but when I do the first layer calibration it does not stick to the bed

Hello all,

Thank you, it was a clogged extruder. Sailed through it once I cleaned it up.

🙂

Ken

RE: Built the machine, but when I do the first layer calibration it does not stick to the bed

I am having a problem with PLA not sticking to the powdercoat surface too, but it appears to be a different problem. I have a very good nozzle height, it's extruding as expected, and the hotbed is hot to the touch and reads correct temperature on the LCD screen.

On my first attempt at a first layer calibration, cleaning first with the included alcohol swath, the filament would not adhere at all. I scrubbed the surface vigorously (alcohol-saturated paper towel) with 70% isopropyl and got about 40% adhesion with the same settings on the second attempt. Scrubbed it down again and got about 70% adhesion. Did it again and got my first fully adhered first layer calibration. It seems to be behaving as if there is some kind of residue on the powdercoat from the manufacturing process.

I finally tried my first model, the Prusa logo on the SD card. It was printing beautifully until it detached from the hotbed after about 5 minutes. More paper towel/alcohol scrubbing and I got to about 8 minutes before it detached. The nozzle height and output are ideal and the print quality looks perfect... until it detaches.

I have 91% isopropyl on order but I'm wondering if anyone else has seen this issue with the powdercoat and if stronger alcohol will help or if I should consider using something slightly abrasive to give the surface a little bit more friction.

RE: Built the machine, but when I do the first layer calibration it does not stick to the bed

Scrub the plate with your hands and a little Dawn detergent and lots of water. Dry it with clean paper towels and never touch the print surface.

Now print. No IPA for this one.

RE: Built the machine, but when I do the first layer calibration it does not stick to the bed

Hello all,

Appreciate the assistance. Learned some new things,open air printers in cold rooms require very different settings than enclosed printers. I was having problems getting my first prints to stick to the bed even after I successfully calibrated Z. Turns out PLA is not happy sticking to the print bed at low temperatures. (Never saw that before) Turned the heated bed temp up, slowed the print down (Way down) and added a skirt and raft.

Printing rakes longer, but it works and sticks. May have to make an enclosure for it or print in a not so cold place.

Thanks again,

Ken

RE: Built the machine, but when I do the first layer calibration it does not stick to the bed

@magician-144

Thanks Ken. I'm printing in a room that's about 68 degrees F.

What heatbed temp did you end up using for PLA?

RE: Built the machine, but when I do the first layer calibration it does not stick to the bed

Set the bed temp to 80 and it sticks, I also put a space heater in the room to get the room warmed up a bit, turnd it off after the first hour of the print. I may have to build it an enclosure.

Ken

RE: Built the machine, but when I do the first layer calibration it does not stick to the bed

OK, this has really got me stumped.

I talked with two tech support people via Chat about this. I even sent them close-up photos of my attempts so they could verify that the nozzle is delivering material properly. They told me to rub the steel sheet with a dry sponge and wash with dish soap and warm water. Didn't work.

I set the bed temp to 80 degrees as Ken suggested and it looked like it was finally working, but half way through another attempt to print the Prusa logo it started detaching until it was catching on the PINDA. Closer but no cigar. Are you using the powdercoat sheet, Ken?

One of the support chat technicians told me to use acetone, but all of the info say DO NOT use acetone on powdercoat.

What to do next???

RE: Built the machine, but when I do the first layer calibration it does not stick to the bed

What to do next???

Maybe you should look for a Prusa user near you. Maybe someone with more experience and access to your printer can help to find your problem.

RE: Built the machine, but when I do the first layer calibration it does not stick to the bed

Do you have a space heater?

I resorted to adding a brim and also made the room warmer, 72 degrees in the room as opposed to 60 in the rest of the house. I have a little Dyson fan that I moved in to the room. After about an hour I was able to turn that off as the printer really does warm the room up.

Also, are you in the USA? If so Target sells 91% Isopropyl Alcohol. Also clean the bed as well as you can. I do not think Aceton should be used on the PEI sheets.

Ken

RE: Built the machine, but when I do the first layer calibration it does not stick to the bed

That was a really interesting Chat... It is the first sign we have had of Prusa supporting dish soap and water scrub on the textured surface.

If it makes you feel any better - adhesion does get better with time and use. I am pretty happy with mine now.

A more aggressive approach is to use the green back dish sponges and use the abrasive side to lightly score the surface. Gently...

Side note: get yourself a smooth PEI plate from somewhere. It will save you a lot of grief just starting up.

RE: Built the machine, but when I do the first layer calibration it does not stick to the bed

I never had the plates before, I always had a bed that I used painters tape and glue stick on, this was very confusing to me until I got the thing figured out.

RE: Built the machine, but when I do the first layer calibration it does not stick to the bed

Success!

My solution was to lightly buff the surface of the powdercoat with a Scotch Brite pad, just enough to knock down the luster slightly. I kept the bed temp at 80 C just for good measure. It stuck tight and separated nicely from the surface once cool.

Thanks for your help!

RE: Built the machine, but when I do the first layer calibration it does not stick to the bed

@kellan_hatch

Outstanding, congrstulations.