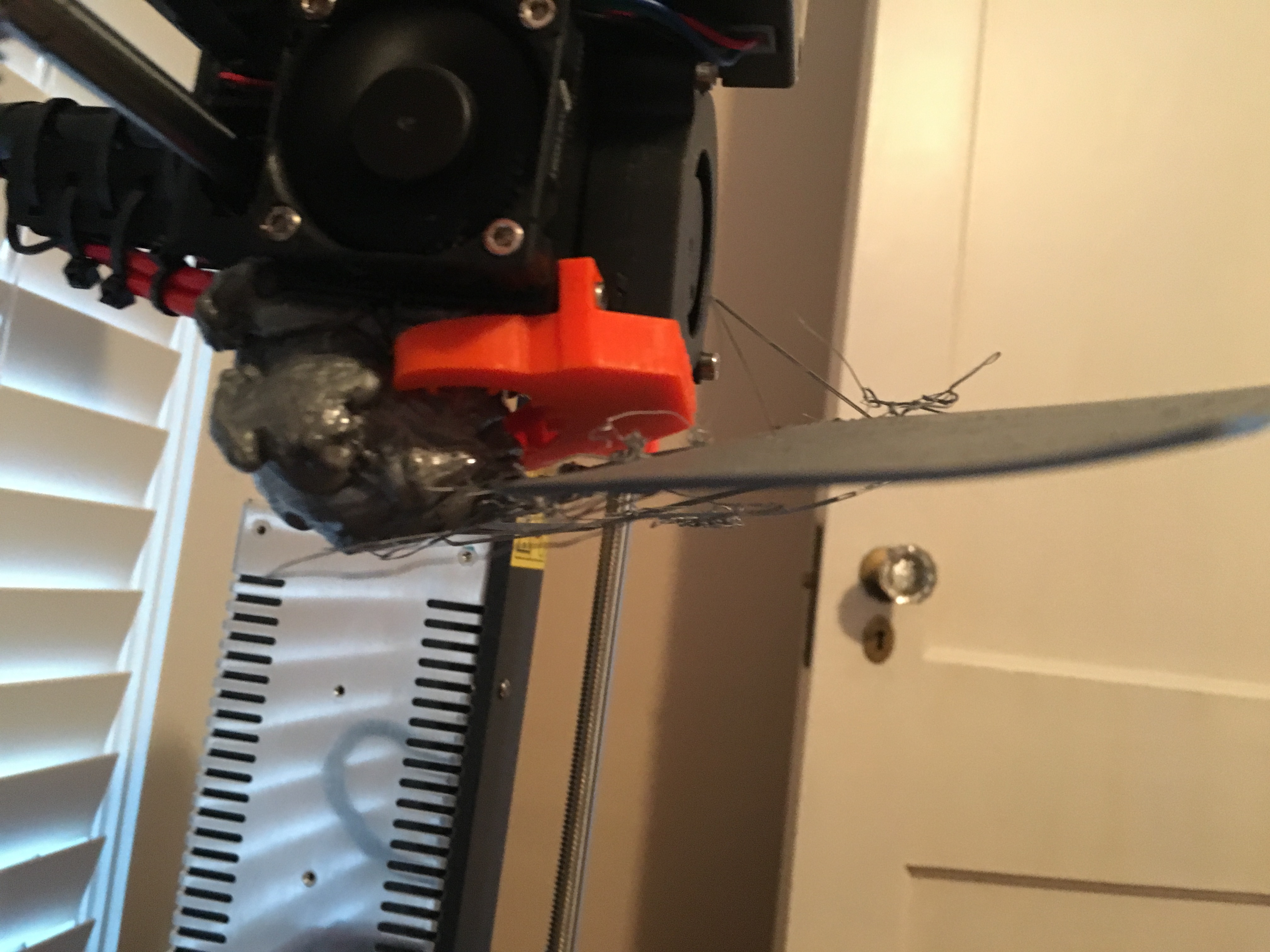

Broken hotend wire, 6 hours of PLA piled up on extruder

Hey Tinkerers,

I finished my new MK3 kit last week and have been loving it. I really took my time on it and was rewarded with zero issues right off the bat. I've made several beautiful prints from the samples as well some prints of my own. This printer is really great!

I had some issues early on with the base coming detached midway through the print but got that resolved and the last day of printing was all smooth. I started a 12hr print last night before bed and unfortunately it came loose shortly thereafter. About 6 hours later I woke up and found a terrible mess all clumped up on the hot end, including the wires...

Like a novice, I started removing the PLA immediately. Maybe it would have occurred regardless, but the blue wire on the hot end (extruder thermistor) broke in the process.

I've gotten the main chunk off and disassembled the E-axis (sigh) so I can work on it freely, but as you can see in IMG_2647 (attached), there is still quite a bit to remove. I wanted some advice on the best course of action from hereon. So far my plan is:

1) Use a heat gun to warm the PLA encased around the nozzle/hotend to aid in the removal process

2) Try soldering the blue wire back to the heating block (probably won't work)

3a) Order a new heater cartridge from E3D's website https://e3d-online.com/heater-cartridge-24v-30w

3b) That unprotected blue wire seems like a really bad idea, and spoils unsupervised printing. Will one of these socks minimize this mess and danger should it happen again? Mostly I just want to keep that blue wire safe. https://e3d-online.com/v6-socks-pro-pack-of-3

4) Reassemble and continue joyfully!

The worst part about this is being down for a few days or weeks because I am having such a great time printing! Thanks to anyone who can offer any tips and advice on my dilemma.

Re: Broken hotend wire, 6 hours of PLA piled up on extruder

Unfortunately you ordered the wrong part. You need a new thermistor. Here is the link for it..

Re: Broken hotend wire, 6 hours of PLA piled up on extruder

Thank you Richard! I haven't actually ordered anything yet so no wasted money. I very much appreciate the link to the correct part.

Re: Broken hotend wire, 6 hours of PLA piled up on extruder

It took a lot of time and effort, but I finally managed to get the hot end separated from the casing, then cleaned of all PLA. I was so glad to be getting somewhere. Then the thermistor wouldn't come out, and I couldn't get the set screw to budge. No amount of heating would save it. Fine I said, I'll be getting the Block & Sock upgrade kit that comes with a new block anyway; I just need to get the hot end and heat cartridge out. After more time cleaning those out, I finally got the heat cartridge screw out and was able to push the cartridge itself some. Not out, just some. Pried up the block just to get it out.

Now for the hot end. Well I had my 7mm spanner for the nozzle and my channel locks on the block just like the instructions and all I succeeded in was tearing up the nozzle. So I basically feel forced into buying a whole new hotend preassembled kit for $80 and I'm so frustrated. People say if you heat up the block things loosen up but how can I do that when the thermistor is busted? So for one $10 item that broke I have to spend $80? WTF! I had 3 glorious days of printing but now I'm regretting it all.

Re: Broken hotend wire, 6 hours of PLA piled up on extruder

You also need the 40w heater cartridge. The heater cartridge with the blue wires is the 30w and with red witres the 40w. Mine has the red wires, and I assume that is the default supplied heater cartridge.

Re: Broken hotend wire, 6 hours of PLA piled up on extruder

It took a lot of time and effort, but I finally managed to get the hot end separated from the casing, then cleaned of all PLA. I was so glad to be getting somewhere. Then the thermistor wouldn't come out, and I couldn't get the set screw to budge. No amount of heating would save it. Fine I said, I'll be getting the Block & Sock upgrade kit that comes with a new block anyway; I just need to get the hot end and heat cartridge out. After more time cleaning those out, I finally got the heat cartridge screw out and was able to push the cartridge itself some. Not out, just some. Pried up the block just to get it out.

Now for the hot end. Well I had my 7mm spanner for the nozzle and my channel locks on the block just like the instructions and all I succeeded in was tearing up the nozzle. So I basically feel forced into buying a whole new hotend preassembled kit for $80 and I'm so frustrated. People say if you heat up the block things loosen up but how can I do that when the thermistor is busted? So for one $10 item that broke I have to spend $80? WTF! I had 3 glorious days of printing but now I'm regretting it all.

Remove the hot end from the extruder so you don't melt the extruder body and use a heat gun or small propane torch to heat the block so you can remove it.

Re: Broken hotend wire, 6 hours of PLA piled up on extruder

Hi Cliff,

can I suggest that you order a spare thermistor, so you don't have to wait, if you have another Blob of Doom!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Broken hotend wire, 6 hours of PLA piled up on extruder

Sorry for the freakout, everyone. It was a frustrating day/night. I slept on it and felt calmer the next day, then just left it for a day. Today, with everything still seized up, I unscrewed the heat cartridge wires from their black Molex connector and plugged them into the output end of a 24V power supply. We had one at work but I imagine you could just use the 24V terminals inside the RAMBO case to do the same. There's no control for the temperature this way so you can't keep it on long but within 30 seconds the hardened plastic was melting away. I turned off the power supply and starting working on the pieces.

The nozzle, now stripped, wouldn't work with the 7mm spanner, even heated. The thermistor, however, slid right out. With a little more heating I noticed the heat cartridge was loose and I was also able to bend the metal of the heat block back in place (I had previously pried it up). Finally, one more short round of heating and two channel locks made the nozzle easy to separate from the heat block, and I was able to salvage the heat break and the heatsink. Hurray! This means my repairs go down to $25 for the Block & Sock upgrade kit which will give me a new heat block, thermistor, and sock. $5 more for a new nozzle and I'm much more at peace with this experience then before. I've certainly learned a lot in the process, like "heat is your friend" and "haste makes breaks"