Belt Tension Readings Seem Wrong

Mk3S+

I was getting Z Axis crashes, so I stated checking the belt tension. The belt tension on the X axis read 216 and Z Axis read 200. However, they looked correct based on the description in the assembly manual.

When I loosened the X Axis to 230, the belt visibly droops. The Z Axis loosened to 220 sags a lot, and it skips teeth on the belt.

Why are the internal belt readings so far off? Should I ignore the readings?

RE: Belt Tension Readings Seem Wrong

The belt readimgs are taken from the total resistance on the axis, so quite possible something else is causing resistance on the x and y axis.

Did you pack the bearings with grease, they cannot be ran dry and can cause quite a lot of resistance if not lubricated

Check the idler pulley screws are not too tight. Pulley should spin freely, check there is a gap between motor pulley and motor. Also check thenY axis rods are parallel.

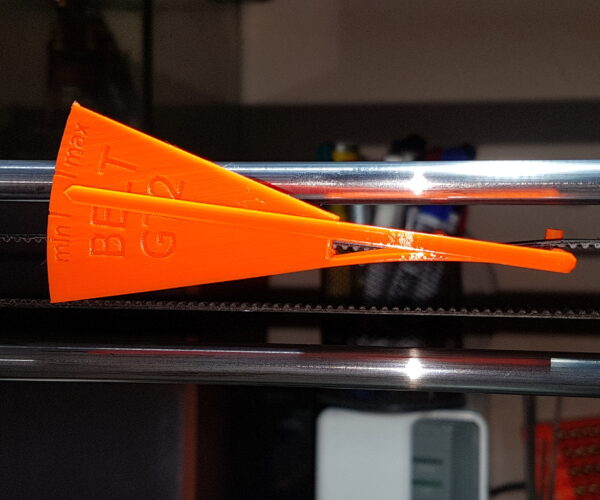

To accurately check belt tension print this in Prusament PETG

https://www.prusaprinters.org/prints/46639-tension-meter-for-the-gt2-belts-of-i3-mk3s-or-prus

Tank you very much!

RE: Belt Tension Readings Seem Wrong

@laurentk

To clarify: the belt readings originate from the motor drive currents; and places on the axis that have drag increase the current required to move the axis. The tension numbers in the Menus can be ignored unless they are too low: in which case you have a serious friction or bearing problem. E.g., 230 is too low, 280 is better, 300 is best.

Did you clean and grease the linear bearing before installing them on the rods? If not, then now is the time to do that.

RE: Belt Tension Readings Seem Wrong

The Z axis moves on the lead screws and should be fixed by running Calibrate Z from the LCD menu.

But you are writing as if it's the X axis you suspect...?

The belt tension figure is a measure of the resistance felt by the stepper when moving the axis. On a correctly set up machine this does equate, roughly, to belt tension.

But other things can affect mechanical resistance.

First, with the power off, move the axis by hand; is is smooth? Does the resistance stay the same over the whole range?

Clean and lubricate the smooth rods, check they are not damaged/scratched. Check the idler pulley is not clogged, out of line, or damaged (loosen the belt and try turning it with your fingertip, is it smooth?)

With the belt loose try turning the stepper motor by hand; is is smooth?

Retighten the belt until it just begins to make a low musical note when plucked...

If the printer works, make your next print this:

https://www.prusaprinters.org/prints/46639-tension-meter-for-the-gt2-belts-of-i3-mk3s-or-prus

It MUST be printed in Prusament PETG or the spring tension will be wrong.

Let us know how you get on.

Cheerio,

RE: Belt Tension Readings Seem Wrong

The belt tension figure is a measure of the resistance felt by the stepper when moving the axis. On a correctly set up machine this does equate, roughly, to belt tension.

This assumption is probably why some Prusa designer thought it would be useful. It's fundamentally wrong.

If the belt were suspended and rolling around on frictionless bearings, there is zero change in current between no tension and the belt's breaking point (over 100 lbf / inch). More tension does not change the belt material's characteristics in a meaningful way as far as rolling resistance is concerned. Readings taken by motor current sensing would be the same for too little tension or at the breaking breaking point.

So at best, what the menu readings are really telling you is the friction coefficient of the end roller bearings involved. And this will change based on lubrication, temperature, and original fitment (tolerance of the bearings). At worst, and in most cases, the numbers only tell you how sticky the linear bushings are.

RE: Belt Tension Readings Seem Wrong

Understood. Nevertheless the values do change a little with different tensions, no bearing is perfect. I assume that the aforementioned designer simply took typical figures from working printers and ignored the many other factors that also affect the reading.

The printed tension meter is easy to use and gives a much more useful measure; experienced users may go by feel and sound and a meter speeds up the acquisition of that experience.

Cheerio,

RE: Belt Tension Readings Seem Wrong

@diem

The tension gauge is simple and probably better than nothing.

Measuring tension using the deflection method or the resonance method is best - but since Gates doesn't specify resonances, we are left with deflection - which the mini-gauges tries to show.

I use a scale, and Gate's equations for finding tension. Extruder to the left, bed to the rear: apply 200 grams to the lowest belt, measure how far it deflects: 6 mm or 15/64ths deflection on X, 5 mm or 12/64ths on Y.

RE: Belt Tension Readings Seem Wrong

If you are trying to get your belt tensions to the right range (assumes you have no issues with drag, or bearing issues, since those are totally different things) download the belt tension gauge pattern and print it in Prusament PETG (only prusament PETG since that is what the gcode was calibrated for). That will let you set the belt tension - which is for managing tooth-slip. Just mount it the way it shows in the print "how to" pictures - and adjust your belt tension to get in the sweet spot.

If you are having crashing issues that don't seem to be effected by lower or higher belt tensions, you probably have a bearing or bearing tightness problem. I have experienced this with the way the bearings are squeezed by the screws on the back of the extruder. To test if you have a dragging issue, disconnect the belt, and move the carriage in X or Y direction by hand - it should smoothly move with no hitches or hesitation. If you have hitches or hesitation, you can change the tension on the bearing holders for both axis - if the original U bolt's on Y are in play, those are notorious for being over-tightened and squeezing the bearing.

I was noticing lines on some box-like prints that indicated I was having some chattering - and found it was the screws on the back of the extruder - turned them a quarter turn to loosen (all 3) and that problem was solved and my box prints started looking nice again.

Belt tension and crashing - usually not related IMO. Drag and mystery crash detection with no obvious globbing or layer shifts - bearing tension, or lubrication are good suspects. If you are seeing layer shifts, look to your pulleys slipping, or over-acceleration (belt tension plays there)

RE: Belt Tension Readings Seem Wrong

bumping this thread instead of creating another on the same topic...

I've read and understood that the "tension" reading is not really a tension reading at all, I understand it's related to the resistance required to move the overall assembly.

Is there a full list of things that could cause the x-axis to read lower (numerically) than the expected range? Here are my specifics:

New build, all bearings were packed with superlube using a syringe. They have enough lube in them that I'm still wiping accumulated blobs of grease off the ends of the smooth rods in between prints.

Prints look great

Y reads 270. X was originally 218. This was with the tensioner all the way backed out so I removed the belt and loosened it one tooth. Without the tensioner it was way too loose, obviously looser than the Y belt. Still, it reads 241. With the tensioner applied a bit it now reads 238 and still feels looser than the Y but not to where I'm concerned about it jumping off.

The two smooth rods holding the extruder are co-planer, as confirmed by a machinist's square on the bed checking both ends of the X axis.

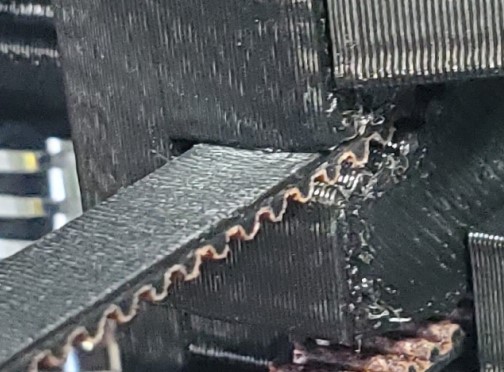

Like many others commented in the online build steps, I had to reverse the X motor pulley to make it so that the belt wasn't pressing up against one of its shoulders, nor was the pulley touching the motor. The idler pulley spins easily, but the belt is up against its one shoulder. I have tried pushing the belt into the extruder housing as far as I can, but I can't get it to go all the way. It is completely in the slot, sunken a bit, but there is still a gap where it could theoretically go a bit deeper. If I were able to get it to go all the way in, then perhaps I could swap the motor pulley back to the orientation the manual uses. Does it matter though?

Hopefully this photo illustrates the belt depth:

I have some Prusament PETG on order so that I can print the tension gauge. But overall, what are everyone's thoughts on the 238 reading? Cause for concern? Is there anything else to check? After a 20 minute print I re-ran the tension test and it showed 244, but the next morning after turning the machine on it was back to 238. Y is always between 268 and 273.

With the printer off I manually move the extruder side to side and it feels firm but doesn't seem to stick really. Sometimes you hit a spot where it seems like it catches but then I'll go over that same range again and it's completely smooth. It's more like if you happen to hit the exact point of a "step" in the motor then it feels like it is caught. Not sure how to explain that, but the motor itself just feels "stout". Overall, it doesn't feel much different than pushing the bed along the Y. Neither slides effortlessly, but neither completely resists or makes strange noises.

RE: Belt Tension Readings Seem Wrong

Update: I printed a little tool to allow me to press the belts in to full depth. That worked great, and now the idler pulley seems even better centered than before. But still hitting the same readings of 239. I'm not sure what else it could be at this point, open for suggestions 🙂

RE: Belt Tension Readings Seem Wrong

But what do your readings in the calibration screen end up being? The past discussions seem to suggest that a person might in fact have the belt tension correct, but there could be some other legitimate concern which causes the value in software to be too high/low. I have not seen anybody suggest that as long as the real belt tension is ok (per the printed gauge) then you are fine to ignore the numbers in the software. Are can you? This is what I'm concerned about...