Bed adhesion

I apologize for repeating a topic that is probably posted a few times a day. I've read many of them. I have tried many of the suggestions. (see below)

I am new to Prusa. I work at an elementary school and have been printing student work for years with Makerbots, with great success. I was able to upgrade to a Prusa, that I've heard so many good things about. I bought the kit, built it, and can not get my prints to stick.

Here's what I've tried:

- many z-axis calibrations

- x, y, z calibrations

- countless first layer calibrations (currently z = -2.375) which seems way too low to me

- resetting system and running wizard multiple times

- constant isopropyl alcohol wiping of base (only 70%)

- bought a satin-powdered base for better adhesion

- manually changed height of superpinda a few times, followed by calibrations

- added start layers

- checked bed temperature and filament temps (60º and 215º)

- tried other filament besides prusa filament

Things seems to go well for about 90% of the print usually, then I'll look over and see that the print has been detached from the plate and printing continues in a random new place depending on how much it has slid. I'm used to taking my Makerbot plates off and flexing them, then using a metal spatula to pry prints off. I can knock all my Prusa prints off with my pinkie finger. My first layer prints come off the bed very easily too, but the initial print is extremely flat because of the -2.375 z adjustment. Pictures below.

Why isn't my filament sticking to the base plate like cement, especially with my heat and z at -2.375? Could my superpinda be hitting the print, an if so, why always near the end? (Going to move my superpinda up and recalibrate today)

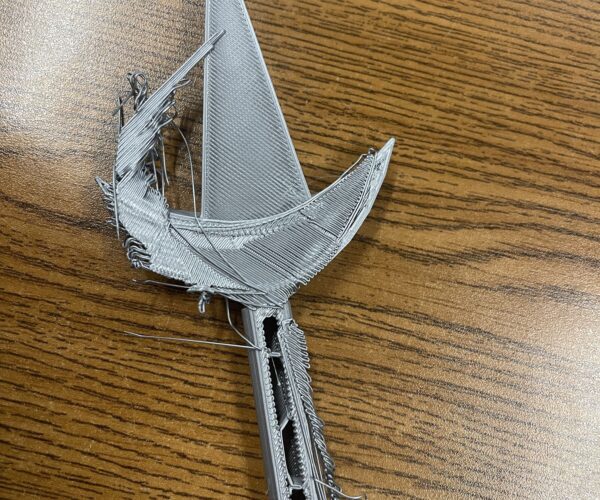

Typical print that slipped near end of print.

side view of initial extrude, taken off base from first layer calibration (paper thin)

top view of initial extrude from first layer cal. (very flat)

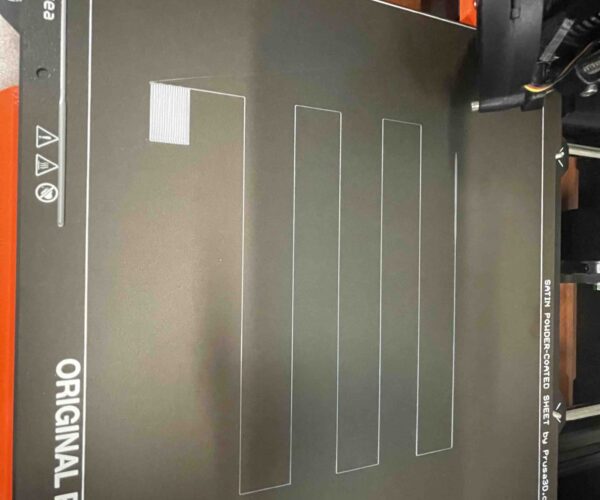

first layer calibration pattern

First extrude on base before taken off plate (very flat)

Two thoughts:

If the first layer Z calibration is going lower than -2 your (super)PINDA is too low; the thread is at 1mm pitch, move it by one thread.

If anything you are calibrated a fraction too low, too much squish, but it should be printable.

Looking at yor pictures I see discolouration and what might be fingerprint patterns on the build sheet 'though it might be your lighting. The standard cleaning advice on thse forums is to use dishwashing soap and hot water especially when there are children around; IPA is not so good at dissolving sugars.

So clean the sheet with dishwashing detergent (Dawn/Fairy) and plenty of HOT water, rinse well and dry with a fresh paper towel. Handle by the edges only.

Clean with IPA between prints.

At the first hint of a problem, use dishwashing detergent and HOT water.

WITH THE SMOOTH SHEETS ONLY - If that's not enough use acetone: once or twice a year at most.

Another possible cause of adhesion issues with larger prints is drafts, in a classroom situation with people moving around, opening and closing door and wndows &c, uneven cooling can cause prints to warp off the plate and up into trouble...

Cheerio,

RE: Bed adhesion

Matthew, just a couple of points:

First of all, the MK3s+ manual states on page 27, that your Pinda setting should not exceed -2.000mm. You could try raising the sensor a bit, but I would refer again to the assembly instructions, and without a steel sheet. Set the sensor one tie height, about 1mm above the bare heat bed. (Bare, because different sheet types will have different offset settings.)

Your Pinda should be at least 1mm higher than the tip of the nozzle, so the Pinda sensor should not be hitting the print.

Do not run the calibration until after you have reset the Pinda sensor height per assembly instructions.

Is the clamp slipping when you tighten the Pinda? If so keep the tie in place and push down on the sensor as you tighten the screw.

It is hard to tell what the print you show should have looked like. Is it a tall print that is laying on its side? Try printing some simple cubes, or other test prints available on the Printables site and see if that makes any difference.

Your calibration and first lower left line extrusion looks fine. Did you change from smooth to satin steel plate without re-calibrating? (you can save the calibrations for different plates)

State specifically what instructions and procedures you used initially set XYZ and calibrate offset.

RE: Bed adhesion

If the first image shows the underside of the print, then the Z height is not properly calibrated. Looks too high as the lines are not properly touching/bonding.

Manual says to mount the PINDA probe 1mm (1 zip cable tip thickness) above the nozzle. Basically you drop the nozzle down to the bed and install/tighten pinda with the cable tie tip under it. this measurement is not scientific. Its just a baseline that you have to fine tune with Z layer adjustment.

Prints should not come of with the touch of a finger. Proper Z adjustment and bed cleaning will solve that. Use dish soap, hot water and soft sponge to clean the bed. IPA only dissolves grease/oils and smears them around (which may help a bit). Dish soap bonds to both, the grease/oil and water molecules. Thus removing them once rinsed.

The included Z calibration print zigzag is does is not sufficient to properly calibrate Z. I use it as a rough baseline and print a bigger part and do a live Z adjustment until I am happy.

If you can't get a properly consistent clean Z calibration, meaning the layers will touch and then somewhere else they won't that means your bed might not be flat. Correct that before you do anything else. Check for debris below and also make sure the heatbed screws are not too tight, in doubt, loosen heatbed screws, heat the bed up to 90 deg C and then slightly tighten them again. The heatbed may warp if the screws are too tight. Prusa tech told me this little trick on the chat.

RE: Bed adhesion

Thank you to everyone who replied. The follow up is that after readjusting the pinda and washing my plates with hot water and Dawn, I have much better adhesion and have yet to have a problem with things staying in place during a print. They still come off very easily, which makes me nervous, but that's a good thing. I'm just not use to it being that easy. Thank you.

RE: Bed adhesion

washing my plates with hot water and Dawn

I wonder how discovered that, it's kindda counter intuative, I've used Dawn as a lub to mate plastic and rubber parts. Anyway, who ever you are, hats off.

RE: Bed adhesion

I don't claim to have thought of this. But I have been championing it for years.

IPA tends to spread finger grease more evenly across the whole build plate. Destroying adhesion... Unless you use loads of IPA. And several wipes.. lots of IPA is more expensive than lots of water and dish soap

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Bed adhesion

I don't claim to have thought of this. But I have been championing it for years.

IPA tends to spread finger grease more evenly across the whole build plate. Destroying adhesion... Unless you use loads of IPA. And several wipes.. lots of IPA is more expensive than lots of water and dish soap

Exactly this. IPA dilutes thes grease around but does not remove it. (Ok a tiny bit will be removed with the tissue).