Bad quality over time

I have been using 2 mk3s machines for around 1 year and 3 months. And over the last 3 months printing quality its been decreasing slowly.

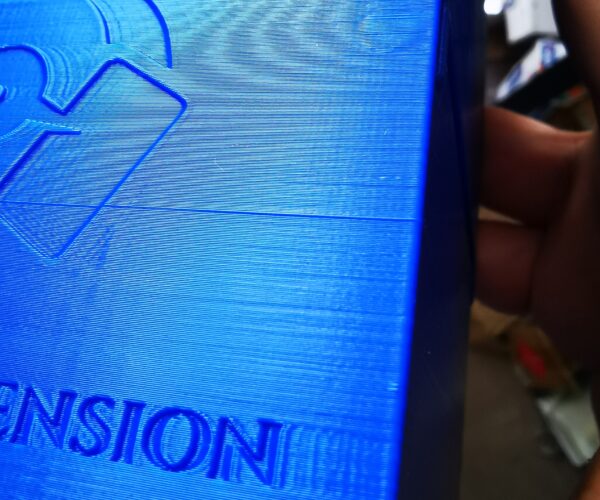

Now I found my 2 machines printing with ghosting and a little bit of layer shift in a few parts of the model. Its really easy for me to notice becuase I am printing boxes.

The same boxes that I have been printing for a while. And now its really easy to see the bad quality.

I contacted support and they told me to check loose components, belt tension and printing temperature. But nothing seems to help.

I am thinking that maybe the motor or the belt its failiing?

Dont know what to check anymore

Best Answer by JPLau001:

It looks like you have horizontal ringing on the vertical surfaces of your print as well as the reported layer shifts.

Check for the following:

- loose screws on the printer. Gently tighten any loose screws you find.

- clean, check, and lubricate your printer's mechanical parts as per the PRUSA's online maintence guides.

- confirm that the belt drive gears on the X-axis and Y-axis motor D shafts have one grub screw tightened perpenduclar against the "flat" part of the motor's D shaft and the second grub screw tight against the round part of the shaft so the gear can only rotate with the D shaft. A loose belt drive gear would cause layer shifts in the same axis as the belt the gear drives.

- Move your X-Axis slowly and confirm that it and its belt move smoothly with no high force areas and that the belt remains flat against the gear. If the belt is clean but moves up and down over the drive gear then you have a streched belt that needs to be replaced as the belt teeth no longer match the gears teeth.

Repeat for the hotbed movement on the Y-Axis. - the heatbed only moves in the Y-axis direction (front to back). Any heatbed "free" movement in the X and Z directions (left - right or up -down) needs to be fixed.

- the entire X-axis assembly only moves in the Z-axis direction (up - down) by having the Z-axis trapezoid rods rotate.

If the X-axis assembly moves up and down slightly, check the screws holding both Z-motors, the screws holding the X-axis to the trapezoid nuts on the Z-axis motor trapezoid rods. Tighten any loose screws you find.

If the trapezoid nuts themselves move slightly up and down on the trapezoid rods then they are worn and you should get replacement Z-axis motors and trapezoid nuts from the Prusa I3 MK3S Spare Parts section of the store. The spare parts section shows up when you are logged into the Prusa store. - check that the X-axis extruder carriage only moves in the X-axis direction and does not move freely in either the Y-axis or Z-axis direction.

If it moves in the Y-axis or Z-axis direction check the screws holding the X-axis carriage back to its front and tighten if required. Aslo look for cracked, melted, or distorted 3D printed parts to replace.

You may need to replace any worn X-axis rods and linear bearings. - check that the hotend is firmly held in the X-axis carriage and is unable to wobble left - right, front - back, or up - down. If it can wobble then check the screws holding the inner 3d printed parts together are all tight. If that does not fix the wobble then you will need replacement 3d printed parts.

- etc.

RE: Bad quality over time

I would recommend uploading some pictures, good vs bad if you can.

RE: Bad quality over time

Have you lubricated the smooth rods? If they get dirty or dry out, you can get layer shifts and reduced print quality. Some lubrication for the smooth rods is recommended. Apply some and move the X extruder and Y bed back and forth. Be sure not to contaminate the PEI print surface.

For the threaded Z lead screws, synthetic lubricant like SuperLube is recommended. Oil can damage the POM nuts.

I've had problems after extended periods with layer shifting that was easily resolved with a bit of lubrication. Do check your belt tension in case they're loosened. They should be tight enough not to sag, be tight enough to twang when plucked, and move easily. You can check belt tension from the printer menu, but the results aren't overly accurate. I just go for good tension.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Bad quality over time

Have you changed nozzles? Could be the brass nozzle is worn out after 15 months of printing.

RE: Bad quality over time

@dmiller2564

Yes my friend I have brand new nozzle in both of my machines and they both are printing with bad quality. I have uploaded some pictures

RE: Bad quality over time

@bobstro

Yes this actually was the first thing I thought. I am in good luck since a while ago I ordered a whole bunch of lubricant for my printers. it takes a while to get here and also its super expensive. I am in Chile.

I did apply some when I noticed for the first time this issue. Curreently now we are moving into summer and here it gets really really hot. Maybe its time to apply again and print a slower time.

I will give this a try and let you know, also it feels like its really hard to make the lubricant get into the rods. any advice?

RE: Bad quality over time

You might also want to measure your belt tension with a scale. The numbers in the firmware are meaningless. Pull up midway on the belt with a scale, about 7 ounces/200 grams, and measure deflection. X should deflect about 1/4 inch or 6 mm, Y about 5 mm.

RE: Bad quality over time

@tim-m30

Tim sorry I didnt get that at all. I think its an english to spanish translation. The only thing I get clear its that "The numbers in the firmware are meaningless"

Could you please explain a little more¿? please thanks

RE: Bad quality over time

Has a picture of how to measure Gates toothed belts. And my math at finding the deflection for X and for Y.

Slide the extruder far left, bed table to the rear. Lift at the middle of the lower belt path. With 200 grams of lift force, the X belt should deflect 6 mm and the Y belt 5 mm.

ps: The idea is to get about 6 pounds of tension on the Gates belts for optimum printing. 2 pounds-force tension is minimum, about 8 lbf is maximum.

RE: Bad quality over time

It looks like you have horizontal ringing on the vertical surfaces of your print as well as the reported layer shifts.

Check for the following:

- loose screws on the printer. Gently tighten any loose screws you find.

- clean, check, and lubricate your printer's mechanical parts as per the PRUSA's online maintence guides.

- confirm that the belt drive gears on the X-axis and Y-axis motor D shafts have one grub screw tightened perpenduclar against the "flat" part of the motor's D shaft and the second grub screw tight against the round part of the shaft so the gear can only rotate with the D shaft. A loose belt drive gear would cause layer shifts in the same axis as the belt the gear drives.

- Move your X-Axis slowly and confirm that it and its belt move smoothly with no high force areas and that the belt remains flat against the gear. If the belt is clean but moves up and down over the drive gear then you have a streched belt that needs to be replaced as the belt teeth no longer match the gears teeth.

Repeat for the hotbed movement on the Y-Axis. - the heatbed only moves in the Y-axis direction (front to back). Any heatbed "free" movement in the X and Z directions (left - right or up -down) needs to be fixed.

- the entire X-axis assembly only moves in the Z-axis direction (up - down) by having the Z-axis trapezoid rods rotate.

If the X-axis assembly moves up and down slightly, check the screws holding both Z-motors, the screws holding the X-axis to the trapezoid nuts on the Z-axis motor trapezoid rods. Tighten any loose screws you find.

If the trapezoid nuts themselves move slightly up and down on the trapezoid rods then they are worn and you should get replacement Z-axis motors and trapezoid nuts from the Prusa I3 MK3S Spare Parts section of the store. The spare parts section shows up when you are logged into the Prusa store. - check that the X-axis extruder carriage only moves in the X-axis direction and does not move freely in either the Y-axis or Z-axis direction.

If it moves in the Y-axis or Z-axis direction check the screws holding the X-axis carriage back to its front and tighten if required. Aslo look for cracked, melted, or distorted 3D printed parts to replace.

You may need to replace any worn X-axis rods and linear bearings. - check that the hotend is firmly held in the X-axis carriage and is unable to wobble left - right, front - back, or up - down. If it can wobble then check the screws holding the inner 3d printed parts together are all tight. If that does not fix the wobble then you will need replacement 3d printed parts.

- etc.