Bad layer adhesion

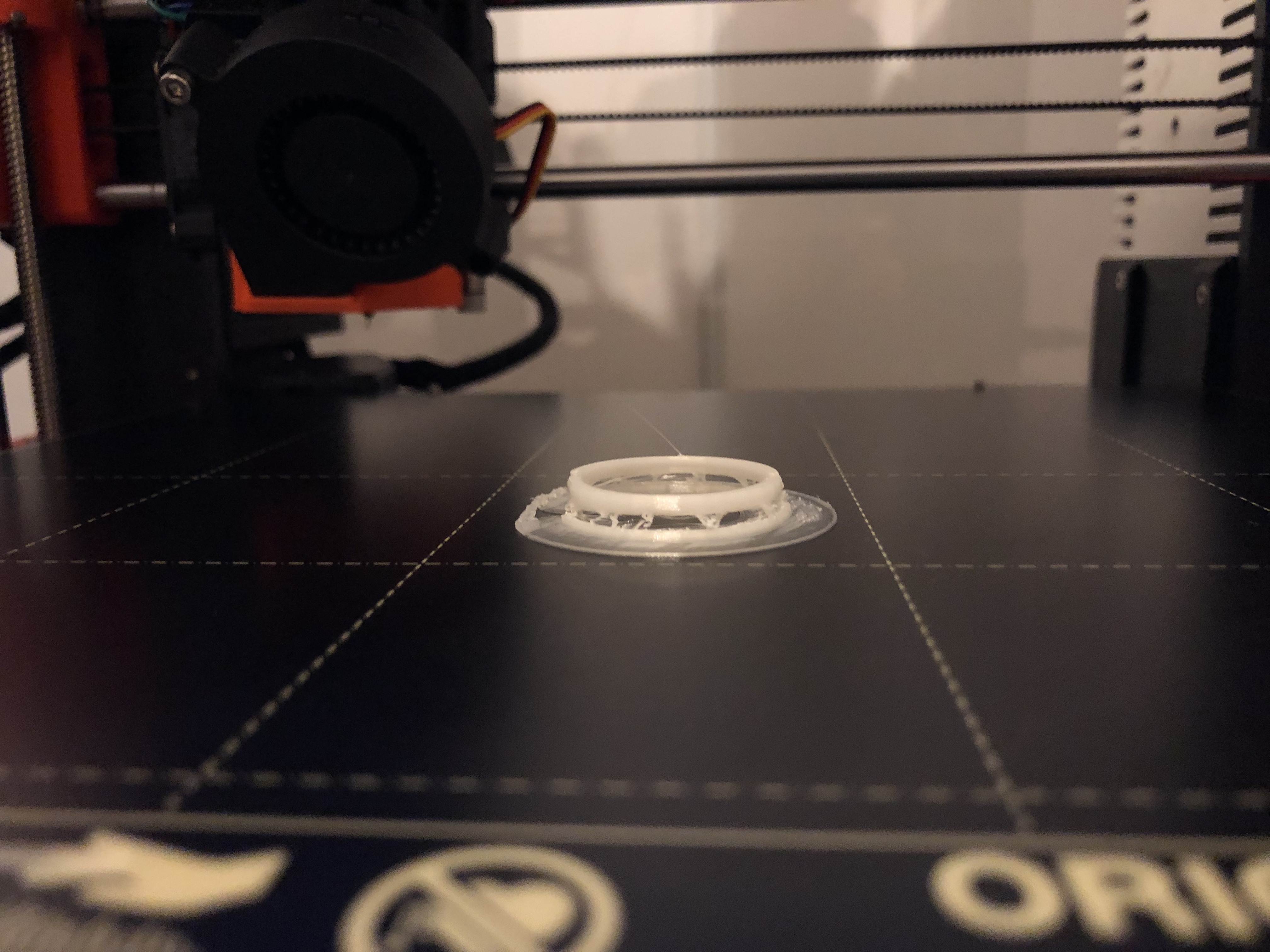

My i3 mk3 is acting weird suddenly. I had no issue printing with for a month but suddenly it started skipping layers:

The first time it did that was using the stock silver filament (PLA), printing with default settings in slic3r PE. The filament sensor told me there was no filament left (while there was, a lot). I unloaded it but the print was already failed by then. Since then I had to disable the sensor because it is constantly warning me about that (I believe that warning is consistent with the moment where the printer skips this layers so possibly some kind of under-extrusion?).

I then tried to change the filament, the process went fine (I switched to vanilla white prusament PLA), and when I started printing a new model (.15 layer height, prusament PLA preset and default settings in slic3r pe), the issue happened again. I ran the first layer calibration again just to check but I don't have any issue on that side (I'm around -0.785 for a nice flat first layer) .

I thought it might be a clogged nozzle issue so I changed the nozzle, burnt myself, ouch, restarted the same print, .... and exactly the same issue happened.

FYI I printed that exact same gcode twice in the past without any issue (it's supposed to be ladybug wings in the end, thus the brim). I also tried printing something else but the same issue happened.

I don't really know what to test anymore.

Re: Bad layer adhesion

Many Mk3 owners run with the filament sensor OFF due to a variety of problems it causes.

It looks like the part slipped off the bed. When was the last time you thoroughly cleaned the steel sheet?

Re: Bad layer adhesion

The part was still sticked to the bed when I took the picture.

I clean the bed between every print with ipa and did an acetone clean a few prints ago.

Re: Bad layer adhesion

dish soap and water maybe? I have yet to need acetone after 9 months or so

I have a Prusa,therefore I research.

Re: Bad layer adhesion

Turn off the filament sensor - there is a known bug in the code that causes layer shifting.

Also, you may want to adjust belt tension and check that the driver gears are properly set. Loosen both set screws, tighten the screw on the FLAT of the shaft first, then tighten the jam screw. Don't tightened them twice. Once for each screw.

Re: Bad layer adhesion

Ok I did a check of the belts, tightened the X axis one a bit, the other one is still fine. I re-aligned the Bondtech gear (I have no clue how that one got misaligned in the first place, I'm sure I aligned it properly a few weeks ago), and redid a proper tightening of the extruder gear door. I also redid a proper z-calibration (with the "my way" method).

I seem to have good first layer adhesion, but that same problem still happens after a few layers, so it looks like under-extrusion but I'm not sure how to fix it. Should I tighten the extruder screws more or less?

Re: Bad layer adhesion

Take another photo or two of a new part that is failing will help; and take them from different angles so we can clearly see X and Y details.