Bad brim - what to do?

Hi,

So i built my first printer this weekend (i3 MK3).

Actually very happy how straight forward everything was (Great job Prusa team!)

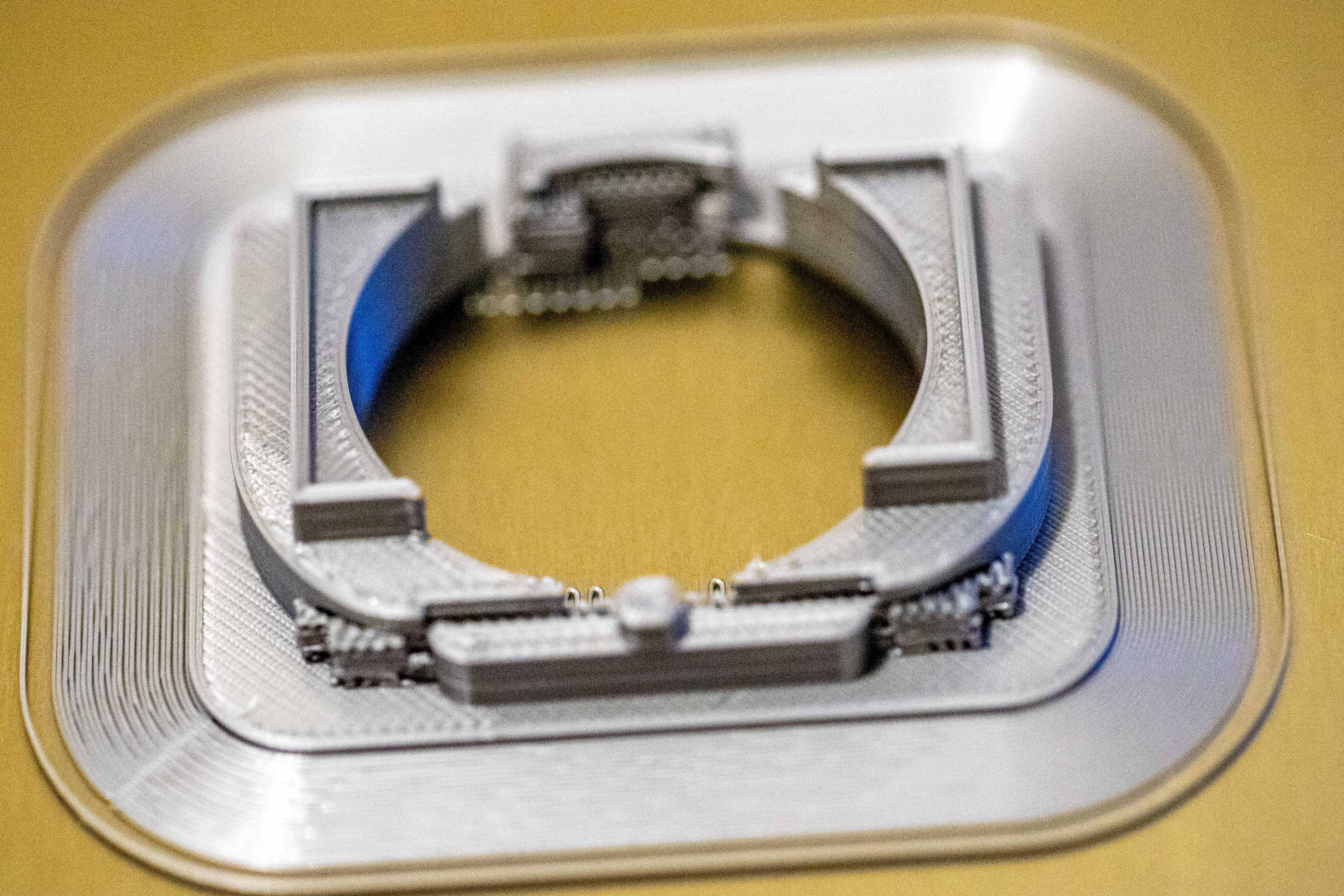

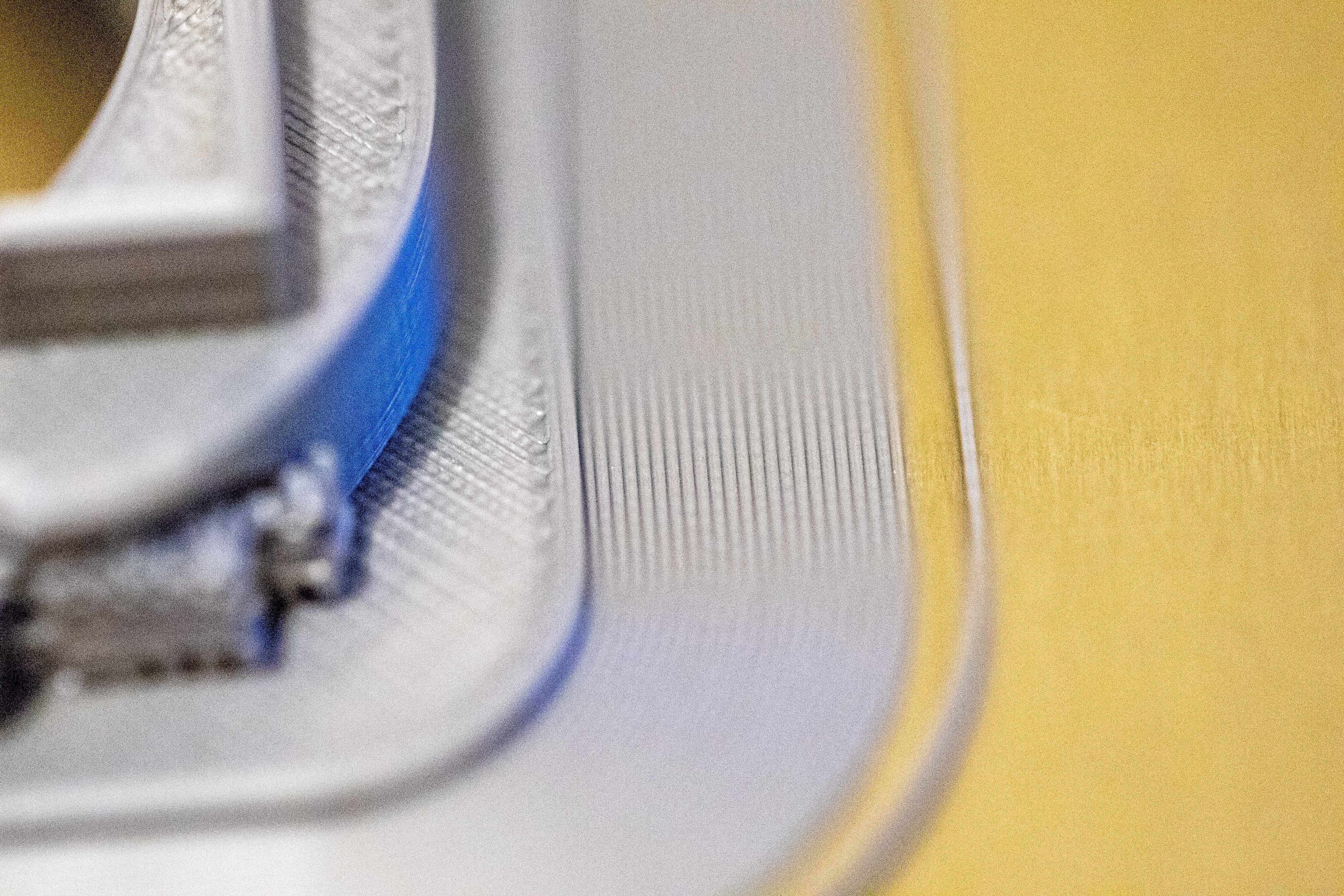

Brim on the left side is no good, right side is good as far as i can see/feel.

What error in calibrating/assembly would cause this?

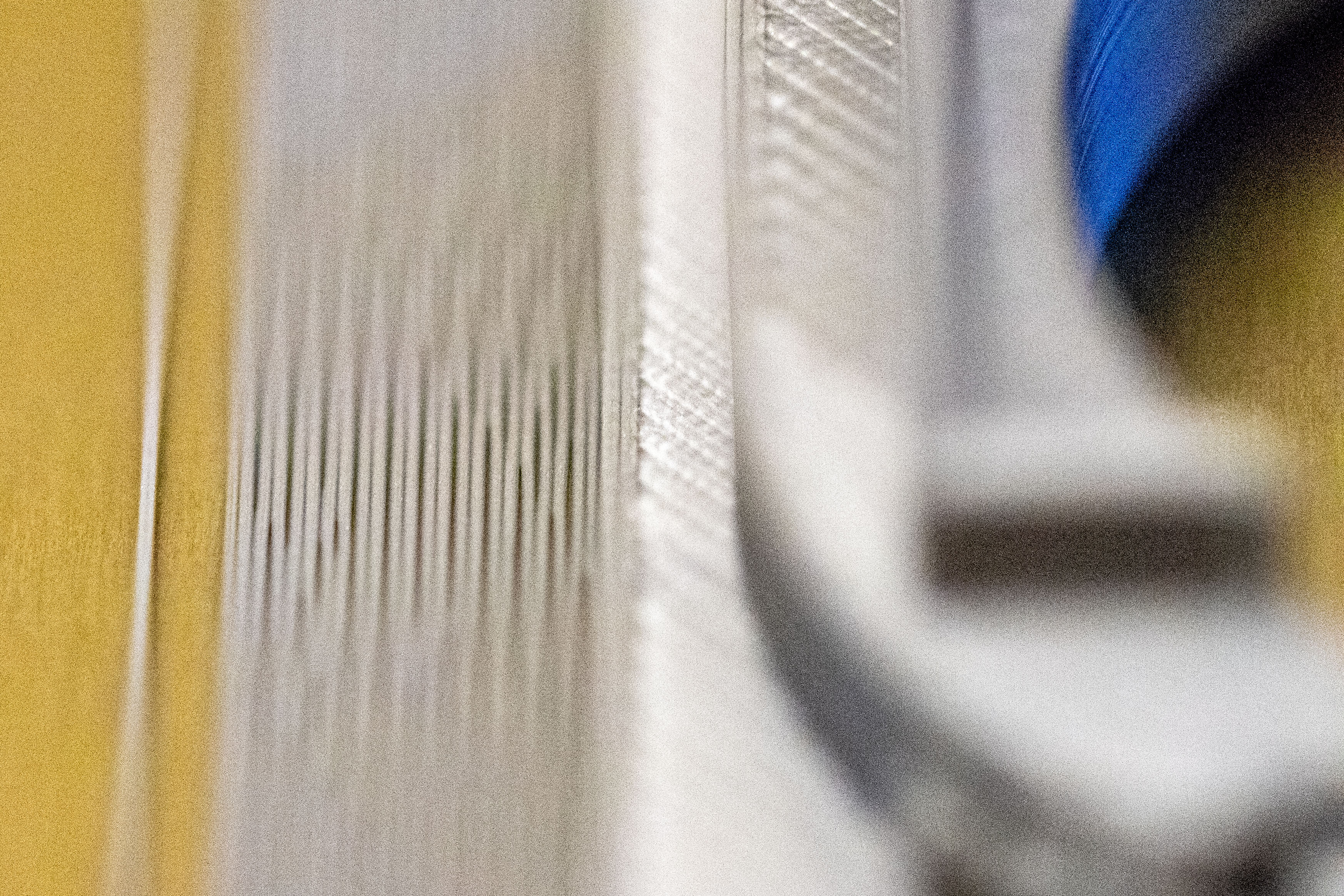

Can also see some imperfections on the sides of the object - is this the extrusion issue?

Link to all photos: https://www.dropbox.com/sh/4jl6wcedddtr5fz/AABOACM_1scE2-a-1PBWdI63a?dl=0

Any help is appreciated!

Thanks!

Eirik

Re: Bad brim - what to do?

If your brim isn't laying down properly, you've got 1st layer adhesion issues. You need to do a Live-Z calibration to get that right. If you get that right, you probably won't need brims as much.

When you've got things set properly, you should be able to drag a finger across your skirt and brim lines without them coming detached. Make sure the bed is clean with a good wipe with 91% IPA and avoid touching it at all costs before the print. You can avoid wiping it down every print if you're careful of touching it. Avoid window cleaner or anything that might contain impurities that will weaken the PEI's hold. Use Acetone infrequently as it's hard on the PEI. An occasional dunk under hot water with dish soap is good too.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Bad brim - what to do?

If your brim isn't laying down properly, you've got 1st layer adhesion issues.

Thanks for your input.

Not sure i follow fully. So this looks lik a adhesion issue or a Z calibration issue - or both?

I've been wiping alot with Acetone, probably should stop that.

Just strange that it is nice on one side and not the other - always that way on similar prints.

If i move the nozzle closer i feel risking it touching the print bed on the right side which already is smooth.

That being said - the live Z calibration was tricky - very hard to see when it looks good.

Any tips here?

Thanks again!

Re: Bad brim - what to do?

Hi Erik,

version 6.1 files at the bottom of the first page.

are you aware of the bed correction menu on the LCD? it allows you to adjust the left, right, front or back ares after live z adjust, heat beds are rarely 100 percent flat, so you may get better results by adjusting the left side too...

if you are using the version 6.1 file that I referenced above,

if the filament strands look to be separate and round, your extruder is too high (increase the negative live Z value

if the surface has ripples in it, your extruder is too close to the build plate the live Z value is too big a negative number

if the surface is smooth, and the strands merged, you are about right

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Bad brim - what to do?

Hi Erik,

version 6.1 files at the bottom of the first page.

are you aware of the bed correction menu on the LCD? it allows you to adjust the left, right, front or back ares after live z adjust, heat beds are rarely 100 percent flat, so you may get better results by adjusting the left side too...

if you are using the version 6.1 file that I referenced above,

if the filament strands look to be separate and round, your extruder is too high (increase the negative live Z value

if the surface has ripples in it, your extruder is too close to the build plate the live Z value is too big a negative number

if the surface is smooth, and the strands merged, you are about right

regards Joan

Thanks Joan!

Tested the file and ended up with -50 on the left side and +20 on the right.

Is this a big error?

the thickness is 0.22 mm but got a solid square atleast.

Maybe i should take the discussion in that thread?

Re: Bad brim - what to do?

some folk have had worse errors!

sounds like you are on the right track

does the bottom face look smooth or does it have gaps between the strands?

might need to increase live z a touch to get 0.2mm thickness, if you feel you need it

it's possible that you are over extruding, and this affects the live Z setting as well as successive layers

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK