An "auspicious" start

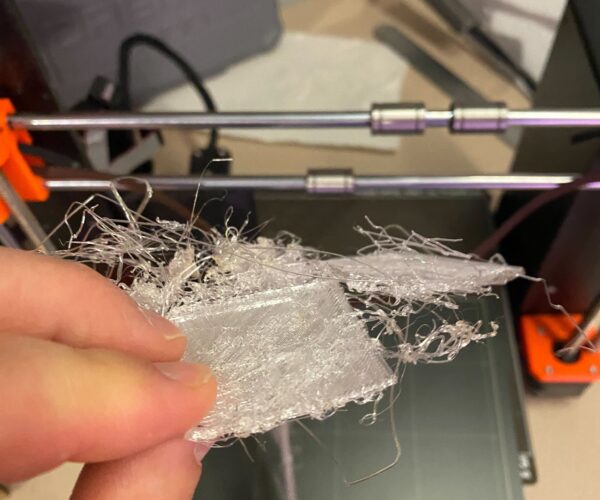

Hey all, just assembled my MK3S+ and encountered some standard issues with the first layer. I think i overlooked some issues in my first self-made print. I currently have a replacement hotend and most of the extruder body printed parts and fan shroud on order. Any notion of how this beast came to be? I switched the filament from PLA to PETG and ensured the temperature settings were at the prusa-recommended levels (1st layer 230, other layers 240) after a series of good (apparently not quite good enough) 1st layer calibrations.

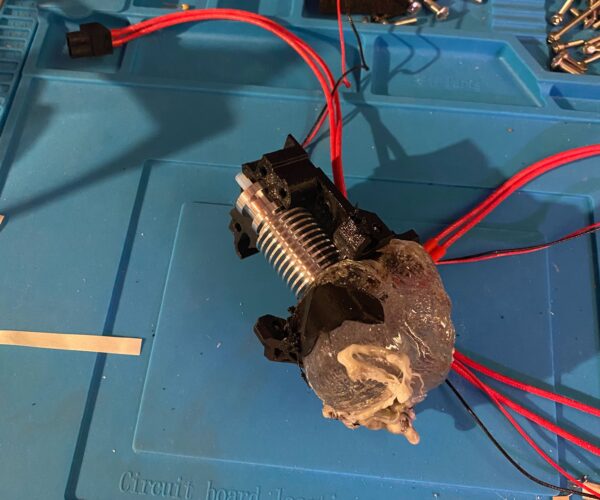

Yes, that's a solidified gob of PETG that has my nozzle and lower hotend encased like some cyberpunk nightmare of a mosquito trapped in amber. I completely disassembled the extruder body and had to pull out my dremel to open up the hotend housing. Something that occurs to me as I write this is that I swapped out the steel sheet for the satin sheet and did not re-run XYZ calibration, if that would have had an effect. There were also some raised ripples at certain points on the first layer that I kinda let slide. The ripples were only found on the longer extrusion paths, the rest looked good. A dirty print bed preventing proper adhesion? Bed temp was 80 for the whole print.

On the upside, the moving parts of the extruder and the IR sensor were all pristine and i didn't have to reorder them..

An excellent 'Blob of Doom.' Search on that term to see how others have dealt with them.

I swapped out the steel sheet for the satin sheet and did not re-run XYZ calibration,

That would do it. In this case it's the most likely cause.

Cheerio,

RE: An "auspicious" start

I'll definitely correct that particular error on the next run in a few days once my parts come...thanks!

It's actually the first layer Z part of the calibration that matters. Once done you can store the profile in the LCD menu; after that it becomes just a menu selection when you change sheets.

Cheeri

RE: An "auspicious" start

Just to clear up the wording: you do not need to rerun xyz-calibration since this only checks the geometry of your printer, which is not affected by a change of the PEI sheet.

You need to run first layer calibration for every sheet you have in use, you can store the results to different sheet profiles in your printer. It works intuitively and you can only access the quick-change after adding your first additional profile. First layer calibration is NOT part of xyz-calibration. Only the initial setup-wizard runs both, one after the other.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!