3D Benchy on a freshly assembled MK3s Kit

Hey hey,

I am completly new to 3D printing and chose Prusa as my starting brand. And i have to say, i am either impressed by the instructions and how detailed they are, or by my craftsmenship, or those 2 together =)

I just assembled my new MK3s Kit and printed the whistle. (it's working, but had some overhang issues when the top layer started)

Afterwards, i recalibrated the first layer and printed a 3D Benchy directly from the SD Card with the bundled filament.

It turned out quite nice when i compare it to a quick google image search of 3D benchy. I think i still see some issues with overhang, especially at all the round printed overhangs (the straight front window on the benchy looks quite alright)

In order to improve the print quality further I want to show you some pictures and i would be happy if there are some suggestions i can try,

top layer

no idea if that turned out good or bad to be honest

slightly even though barely visible overhang issues on that front hole on both sides

overhang issue on the upper part of the door

overhang issue on the upper part of the door

overhang issue on the upper part of the door

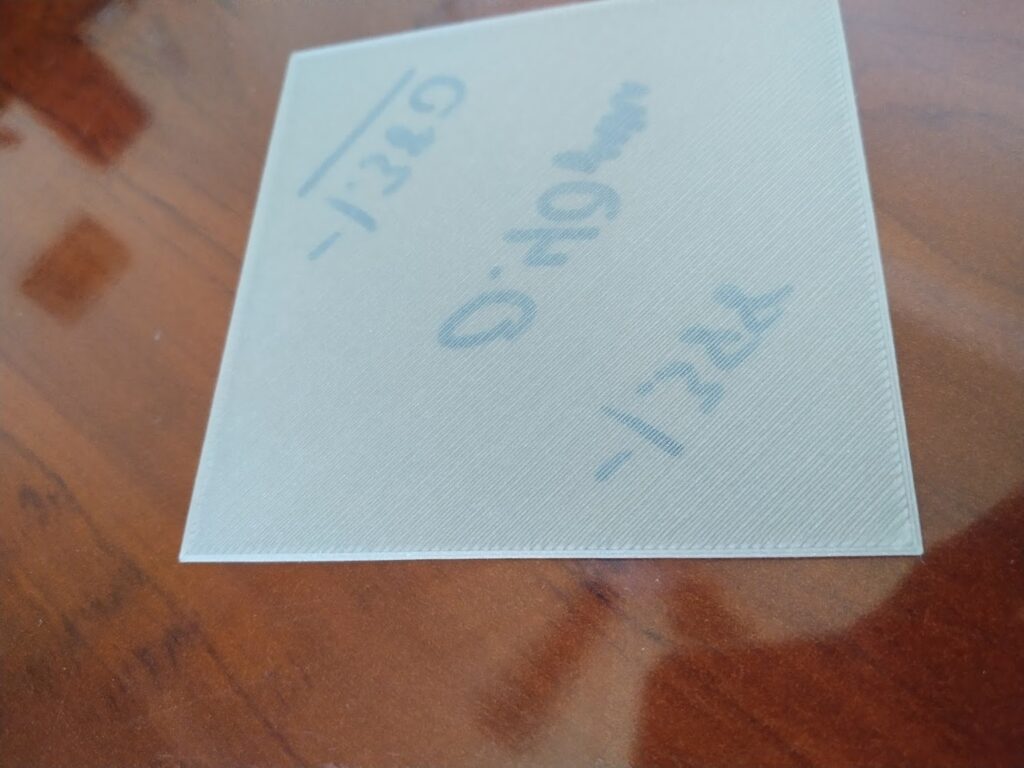

I can barely read the text, so something must still be off, i think it should read 3D Benchy or something

while printing you could hear a little click, when it did the overhang for the first time, i assume nozzle is slightly too low?

other door with overhang

Thanks for taking time to look through this!

greetings from germany

RE: 3D Benchy on a freshly assembled MK3s Kit

For a first print, using the provided g-code file, that's actually quite good. No matter what you do, there will always be some amount is issue with the tops of the rounded openings. It's a side effect of slicing into layers. You can make it less noticeable by slicing the model at smaller layer heights, but it will always be there to some degree. It's mathematics and geometry thing.

From the bottom, your first layer looks good, so it's not too high. Could be too low.

Before you go any further, do an "e-step" calibration. This will ensure the extruder is moving the correct linear distance it was commanded to. If it is off, everything will be off by sometimes varying amounts. Here is a reasonable guide: https://mattshub.com/blog/2017/04/19/extruder-calibration. Once that is done, go back to first layer calibration.

You didn't say how you did the first layer calibration, but I'll assume it was using the firmware calibration. If so, try printing a 75mm square that is 0.2mm thick (one layer) and adjust the live z till the top looks like this, or as close as you can get it.

The bottom should look something like this.

It's more important to make sure the bottom side is solid and all the extrusions as squished together than it is to make to top side absolutely smooth. What you don't want is the top looking like this.

You can see the very rough surface under the -1.380. That's bad.

Once you get a decent first layer, it's time to do an extrusion multiplier calibration. The goal is for the width of an extrusion, when printed, to match the width in the slicer. If we command the extruder to make a 0.42mm wide line, it should measure as close to 0.42mm as we can get it. This is something you should do at the start of each roll of filament, or at least for each filament type (manufacturer+material+filler).

https://help.prusa3d.com/en/article/extrusion-multiplier-calibration_2257

I find that a pair of cheap Amazon digital calipers is sufficient. Take several measurements at several places along each side. There will be some variation, but you want it generally centered around the expected width and withing +/-0.01mm since most cheap digital calipers have two digits after the decimal point. That works out to be +/-2.22%. Adjust your extrusion multiplier as needed.

Once you've done that, go back and re-do your first layer calibration. If you had to adjust your extrusion multiplier much at all, you will likely find that you need to adjust your live Z, and that you can now get a much more uniform top and bottom surface now.

There are certainly more advanced calibrations you can run, but that's good starting point. Because the extrusion multiplier is part of slicing, you can't use pre-sliced models and have it apply. You could change the firmware flow setting, but you have to remember to do that every time you change filament profiles. So, download benchy and slice it yourself. Using the default settings for Prusa PLA, other than changing the extrusion multiplier value as needed, should be a good starting point.