0.6 Nozzle switch seam issues

Setup:

- Printer: Prusa i3 MK3S+

- Firmware: 3.13.0

- Prusa Slicer: 2.6.0

- Nozzle: E3D V6 0.6mm

The only upgrade from the stock Prusa i3 MK3S+ was the nozzle change from 0.4 to 0.6 (genuine E6D from Prusa shop).

I am also only using Prusament (PLA/PETG) with the default Prusa Slicer print profiles for 0.6 nozzle.

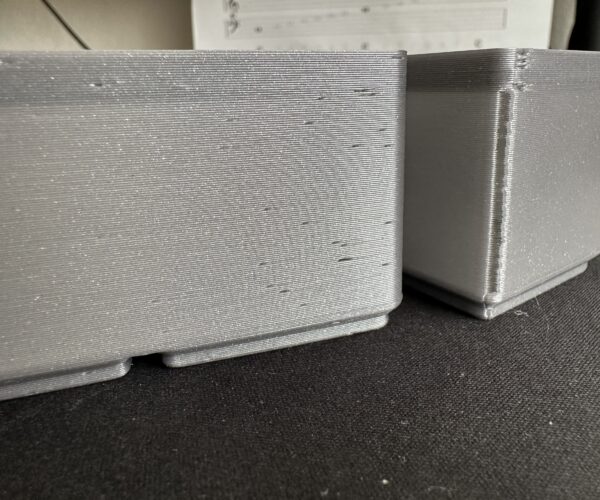

When I print with seams the are always open and not really closed anymore ... would could be the issue?

RE: 0.6 Nozzle switch seam issues

Around what layer height are you using for your prints? (That could be a factor for the issue)

RE: 0.6 Nozzle switch seam issues

Check to see if any filament is leaking (in case you didn’t screw the nozzle tight enough)

RE: 0.6 Nozzle switch seam issues

This doesn’t happen often with pla and petg, but based on the pictures given, it may be that the filament has absorbed some water and you need to dry it out.

RE:

Check to see if any filament is leaking (in case you didn’t screw the nozzle tight enough)

No leaks - already printed a couple of 1 KG spools. I guess that should have been noticeable by now ...

RE:

This doesn’t happen often with pla and petg, but based on the pictures given, it may be that the filament has absorbed some water and you need to dry it out.

Happens with PLA as well as PETG. Also tried this with a brand new and sealed Prusament spool.

Also after opening I store my spools in a custom low-humidity enclosure (<10%, https://www.printables.com/model/116955-filament-dry-box-4x-ikea-samla-22l).