Filament-Verstopfung beim ersten Druck-Versuch / der Kalibrierung

Hey,

wir sind ganz neu dabei und haben in 15 Stunden zu 2. unseren neuen Drucker aufgebaut und sind grade ziemlich deprimiert. Nachdem die ersten Kalibrierungen super geklappt haben, ging es um die Kalibrierung der 1. Schicht.

Leider kam da nie etwas raus. Meine Freundin hatte das PLA eingelegt und beim ersten Versuch wohl nicht weit genug rein geschoben. Es gab auch keine Unterstützung dabei, weil es ja eig. eine Einleghilfe geben sollte (vllt. nicht beim 1. Start / der Kalibrierung?).

Jedenfalls kam einfach nichts raus, wir haben das Filament wieder entfernt, neu angeschnitten und tiefer rein geschoben.

Dann neu versucht und es kam erst nichts, dann ein paar Fäden, aber hat nicht so wirklich funktioniert. Wir haben super viele Beiträge und Videos und alles mögliche gelesen, was wir tun können und sind nicht weiter gekommen:

Das Filament ließ sich auch nicht mehr raus ziehen, auch mit geöffnetem "Seiten-Fenster" steckte es tiefer richtig fest. Entladen hilft gar nicht und bei Druck-Versuchen kommt dieses "Klacker-Geräusch", von dem auch viel geschrieben wurde => tut sich einfach nichts.

Wir haben dann ein Video gefunden, wo das Filament durch das "Seiten-Fenster" abgeschnitten wurde. Das haben wir auch gemacht und das Filament nun oben wieder entfernen können. Unten ist es jedoch immer noch fest und wir können nicht wie im Video von oben nach drücken, damit der Rest geschmolzen und entfernt wird.

Natürlich haben wir auch die Temperatur erhöht, damit es sich selber vom PLA befreit und die Akkupunktur-Nadel von unten benutzt. Soweit die Nadel reicht, fühlt man keinen Widerstand...

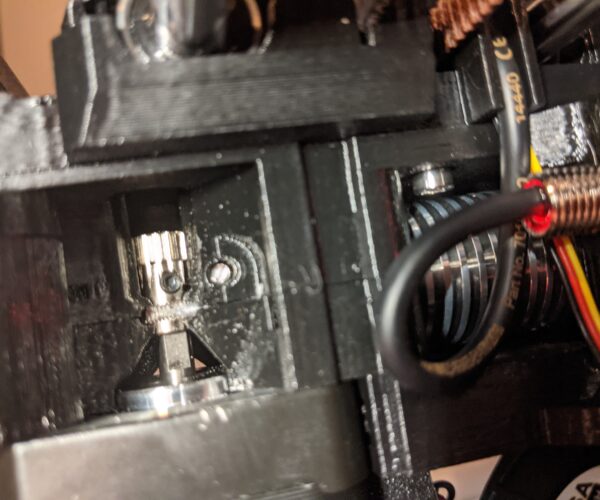

So sieht es jetzt vom Seitenfenster aus, halt mit einem Stückchen PLA noch Richtung Extruder und ja...:

Wir sind ziemlich ratlos. Nach der ganzen Arbeit sehr deprimierend für uns, dass wir nicht mal einen Druck hinbekommen haben, bevor es an so eine Fehlersuche gehen muss...

Wir hoffen, jemand hat einen Tipp / die Lösung für uns.

Danke und Grüße

Best Answer by JoanTabb:

@acanis

Hi, have you tried removing the nozzle and heating/pressing again?

if that doesn't work, you probably have to strip the hot end out of the printer

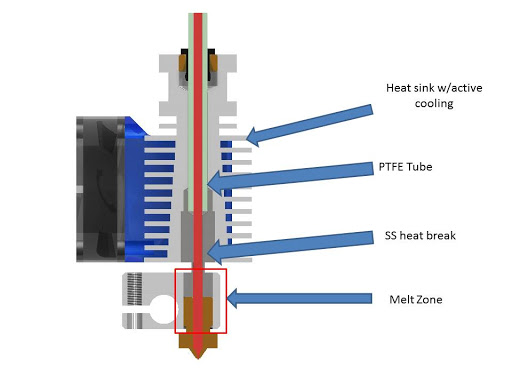

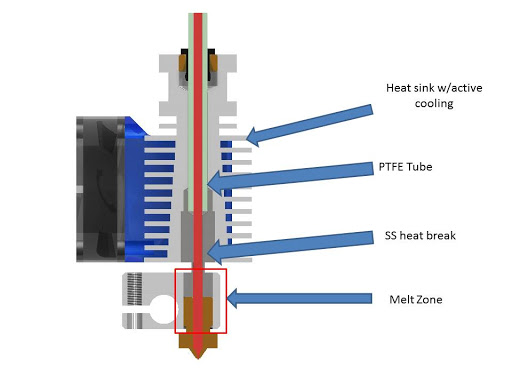

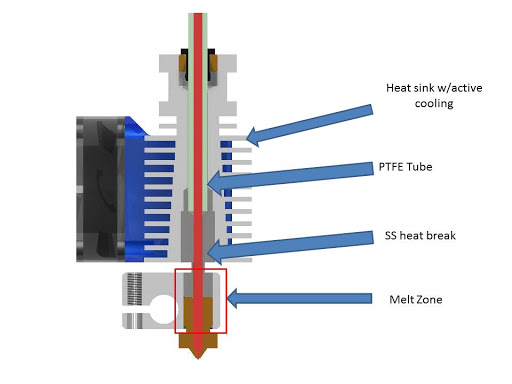

the picture above is a cross section of an E3Dv6 Hot end...

the filament in your printer may have jammed in the stainless steel heat break or the PTFE Tube. the problem is that the filament will not soften in the section inside the heatsink, because the fan is cooling that area,

be careful, If you take the fan off whilst heating the extruder, in situ, the extruder housing may melt...

regards Joan

RE: Filament-Verstopfung beim ersten Druck-Versuch / der Kalibrierung

Leave the bondtech door open,

Raise the extruder perhaps 60mm (Height is not critical, as long as it is well above the build plate) heat the extruder to ABS temperature take a long 1.5mm hex wrench (Allen key) and insert the long end, down the filament path, until it touches the end of the filament below the bondtech gear..... when the extruder has been up to ABS temperature for a couple of minutes, press firmly on the Hex Wrench, to press the filament into the extruder. this should clear the blockage.

If you are successful, reset the temperatures to PLA, close the bondtech door, insert the tension screw and spring tighten a couple of turns, then try reloading the filament.

if that fails look in the Prusa Knowledgebase articles

https://help.prusa3d.com/en/article/clogged-nozzle-hotend-mk3s-mk2-5s_2008

regards Joan.

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Filament-Verstopfung beim ersten Druck-Versuch / der Kalibrierung

Hey,

thank you. We did try that already and we found the site you did post.

If we press on the Hex Wrench and its not moving - what can we do?

- Press even harder?

- Change the tube https://help.prusa3d.com/en/guide/how-to-replace-a-ptfe-tube-mk3s-mk2-5s-mmu2s_21664

2nd would be the same like one cause from the site you posted "Filament stuck in the PTFE tube". If nothing is moving from pressing the Hex Wrench, should that be the reason? I cant feel anything with the needle, but the tube should be longer than the needle... Shouldnt the heat melt anything in the tube?

RE: Filament-Verstopfung beim ersten Druck-Versuch / der Kalibrierung

Hallo,

wie weit geht das Filament unter die Zahnräder?

Kann es eventuell sein, das ihr den PTFE-Schlauch falsch rum montiert habt und das Filament daran scheitert weiter nach unten zu kommen?

Man kann Dir den Weg weisen, aber gehen musst du ihn selbst - happy Printing 🙂

RE: Filament clogging during the first print attempt / calibration

@acanis

Hi, have you tried removing the nozzle and heating/pressing again?

if that doesn't work, you probably have to strip the hot end out of the printer

the picture above is a cross section of an E3Dv6 Hot end...

the filament in your printer may have jammed in the stainless steel heat break or the PTFE Tube. the problem is that the filament will not soften in the section inside the heatsink, because the fan is cooling that area,

be careful, If you take the fan off whilst heating the extruder, in situ, the extruder housing may melt...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Filament-Verstopfung beim ersten Druck-Versuch / der Kalibrierung

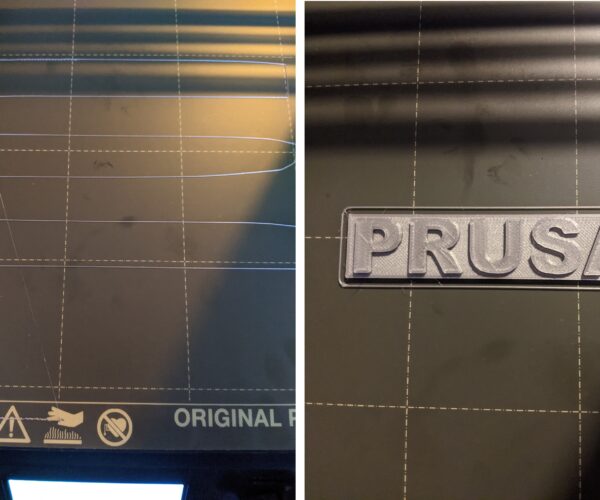

Ok, es war echt anstrengend, aber wir haben das Filament aus dem Schlauch entfernt (siehe Bild).

Unsere Frage ist: Warum ist das Filament nirgends angeschmolzen??? Ist bei uns irgendetwas kaputt, sodass es nicht schmilzt oder kann man sagen, warum das Filament so tief in den Schlauch geht, ohne dass es anschmilzt? Richtig schlimm wäre, es wieder zusammen zu bauen und es klappt immer noch nicht :D. Den Extruder auszubauen war wirklich anstrengend...

Ok, it was really exhausting, but we removed the filament from the tube (see picture).

Our question is: Why is the filament nowhere melted??? Is something broken with so it doesn't melt or can you tell why the filament goes so deep into the tube without melting?

It would be really bad to put it back together and it still doesn't work :D

Removing the extruder was really exhausting ...

RE: Filament-Verstopfung beim ersten Druck-Versuch / der Kalibrierung

@acanis

Hi, have you tried removing the nozzle and heating/pressing again?

if that doesn't work, you probably have to strip the hot end out of the printer

the picture above is a cross section of an E3Dv6 Hot end...

the filament in your printer may have jammed in the stainless steel heat break or the PTFE Tube. the problem is that the filament will not soften in the section inside the heatsink, because the fan is cooling that area,

be careful, If you take the fan off whilst heating the extruder, in situ, the extruder housing may melt...

regards Joan

Ah great picture, thank you very much! 🙂

But how can it stuck before the Melt Zone? Do we have to fix that or can we just put it together again?

And yeah, removing the nozzle before following your first tip, is a good idea for the next time, we get this problem :)!

RE: Filament clogging during the first print attempt / calibration

@acanis

It is possible that the nozzle was blocked and stopping the filament going through the extruder...

as to why the filament wasn't melted,

If you look at the Diagram, above the Melt zone is there the filament should be molten, the Heatbreak has a very narrow portion just above the melt zone, which is intended to isolate the melt zone from the rest of the extruder assembly,

the aluminium heatsink with active cooling, is intended to keep the rest of the heatbreak cool. and prevent the filament from melting too early, the PTFE Tubing is intended to reduce the friction on the filament as it passes through the extruder, and to stop the filament snagging on the gap between the aluminium heatsink and the stainless steel heat break in the area where the Blue arrow, labelled PTFE Tube is, in the diagram

when your printer is working, the cold filament is pushed into the top of the PTFE |Tube, whick guides it into the heatbreak tube and then into the Melt Zone...

the E3Dv6 extruder has a limited capability to melt plastic, for PLA, that is approximately 15 cubic milimeters per second.

all the time that the extruder is feeding filament the melt zone will be trying to melt it in preparation for extrusion, when the extruder gets tot he end of a print section, there will usually be a retraction command in the printer G code, this withdraws the filament from the melt zone by a tiny ammount. on the Mk3 series of printer this is typically a default value of 0.8mm this filament may be hot and is retracted into the thin 'Neck' of the Heatbreak, and hopefully this takes the pressure off the filament in the melt zone, to prevent stringing through the nozzle.

IF YOU MAKE THE RETRACT|ION T|OO LONG, too much hot filament will be drawn through the heatbreak and into the 'Cold Zone' of the extruder (the upper section of the heat break, which is surrounded by the cooling fins,

this over retraction can cause a blockage in the heatbreak tube, this sort of Blockage is most apparent during intense retraction periods, for example when there is a lot of detail on the model.

If the printer nozzle is partially obstructed, for example if the live Z is too large a number and there is insufficient space between the nozzle and the build plate for the filament to pass freely, you can get a situation where molten filament is forced back into the heatbteak neck and the cold zone of the heatbreak, where it will harden and jam the works up...

couple this with larger than normal retractions and you can get blockages further up into the cold zone...

If your printer is in a high ambient temperature ( some very warm countries, or Enclosures) the combination of reduced cooling , perhaps a hot extruder motor feeding het into the filament through the Bondtech gears and reduced cooling inside the cold end of theextruder, and it is possible to get PLA to melt well inside the cold end of the extruder, this can cause a band of molten filament to form in the slight gap between the PTFE tube and the stainless steel heatbreak. this can also cause a blockage in the extruder...

If the filament blocks in the extruder, and you try to pull it out of the extruder from the top, it is possible to pull a blob of filament into the PTFE tube, where it hardens and then refuses to either pull out of push in...

In order to minimise blockages I usually run my printer with 0.4mm retractions for PLA and PETG, and 0.0mm retractions for TPU.

If I get a blockage I generally increase the nozzle temperature and firmly PUSH the filament into the extruder (whilst the nozzle is in a clear space,) in order to encourage the blockage to move down and melt ... More often than not, this works for me. I have had one blockage recently where a defective piece of filament totally jammed the heatbreak, and I had to dissassemble the heat break, then heat it over a gas burner, and push a 1.5mm rod into the bottom of the heatbreak in order to push the rubbish out of the top of the heatbreak (the supplier replaced the roll of filament because that batch was substandard)

It is unfortunate that the time you are most likely to get blockages, is when you are new to printing, and learning what makes the printer run well, and that is also the time when you are least prepared to deal with issues... and most likely to miss assemble the extruder after clearing a blockage, and accidentally increasing your liklihood of getting more blockages.

ALWAYS check your Live Z after working on the extruder... changing nozzles, clearing blockages , replacing PTFE tubes etc...

because the nozzle position may have moved a little!

I hope you are now back to printing successfully,

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Filament-Verstopfung beim ersten Druck-Versuch / der Kalibrierung

Thank you very much! 🙂

It helped us a lot.

We have problems with the calibration now: First level calibration doesnt look good. Manual says: PINDA-sensor needs to be higher

If we change the PINDA-sensor just a little bit higher, the XYZ-calibration fails...

So I tried to print our first object and it looks quite good 🙂 But I used some random Live Z-calibration-value and the first level calibration didnt look good again...

I add both pictures. What do you mean: Can we just stay like that or do you have an idea from the pictures? 🙂

---

After reading your text and fixing the problem, I think we failed, because we didnt wait for the autoload support. We didnt put the filament deep enought and after that TOO deep... Now we understand how it works and how do load the filament...^^

RE: Filament-Verstopfung beim ersten Druck-Versuch / der Kalibrierung

Its working better now. Not perfectly, but its fine for now ^^