Mosquito Hotend Testing

Short notice, but on Sunday, May 20th, I have the designers of the Mosquito Hotend coming by my house to test it with the MK3, MK2s, and MK2s-MMU.

https://www.sliceengineering.com/

While I have designed and printed various 'cage modifications' to mount the Mosquito on the stock Prusa's and will test with existing heater cartridges, thermistors and firmware, my question is whether I can go to the next step and test higher temperatures.

Slice Engineering is bringing a 50W heater and high temp thermistor and I can modify the firmware to exceed the 295*C limit just to test (no priniting) but can the stock power supply and/or the Rambo/Einsy handle this? I expect I might blow a fuse, which I can handle. but I do not want to damage the boards.

Any insight from this that have modifying their Prusa's to print at higher temps would be welcome. Thank you. Jerry.

P.S. = Sorry for double post in MK2 and MK3 forums but new format does not allow me to cross-post and wanted to get feedback on both.

Here is the link to the other post if we can make it the primary response post:

https://shop.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles--f65/

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)

Re: Mosquito Hotend Testing

Slice Engineering is bringing a 50W heater

Pushing the fuses to extreme on the Mk2 (12V and 5A fuse for heat, motors & fans)

The stock 40W heater will take you well over 295 degrees. Their thermistor will probably not be OK with the firmware.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Mosquito Hotend Testing

Thank you for your quick response. So as I understand this if I do this I should concentrate on the MK3, right?

However, in an earlier thread I saw you stating that the stock thermistor will not handle the higher temps, say 350*C. So if the one they are bringing would not be okay with the firmware then I guess this is non-starter and I will just focus on fitting the Mosquito to stock configs and documenting any differences to E3D V6 with PLA and PETG and MMU.

Unless you have any other ideas to test while they are here?

Thank you again, Jerry.

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)

Re: Mosquito Hotend Testing

Correct, the Semitec thermistor is good to about 290.

If you are going to amend the firmware, it does contain a set of tables for quite a few different types, but they may not be as accurate as the semitec.

Peter

EDIT: Configuration_prusa.h around line 500 - the supported thermistors.

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Mosquito Hotend Testing

Thank you again. I am looking at that section of the firmware now. I will wait and go over the options with the engineers on Sunday and then form a plan. If they want to exploit the high temps capable of the Mosquito using the Prusa then I am also sure the mounts I have created would have to change based on PETG glass transition temps.

Jerry.

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)

Re: Mosquito Hotend Testing

use pt100 thermistor + amplifier . its good up to 400c and more accurate.

whats so special with this hot end ?

Re: Mosquito Hotend Testing

whats so special with this hot end ?

My initial attraction to it was to see if it could offer better reliability, consistency and convenience. To wit:

- you only need to use a 7mm socket to change nozzles (no two wrenches required as it is one mounted unit)

- you do not have to heat the nozzle in order to change it

- the filament feed tube is an integrated metal tube from the top of hot end to the nozzle allowing no potential gaps for a bead to form on retraction within the hot end

- the heater and thermistor cables are inline with their probes, and not bent at a 90 degree angle, so the cables are not pinched and do not run alongside the heat block

- It was designed here in Florida 💡 and is being manufactured in Indiana 😯

So, working from this view I only had a few hours on Sunday with the hot end. It was just announced at the MRRF 2018 and they sold all they had so the engineer only had the one hot end in his pocket but he graciously agreed to stop by on his way from Miami to Gainesville so we could 'play'.

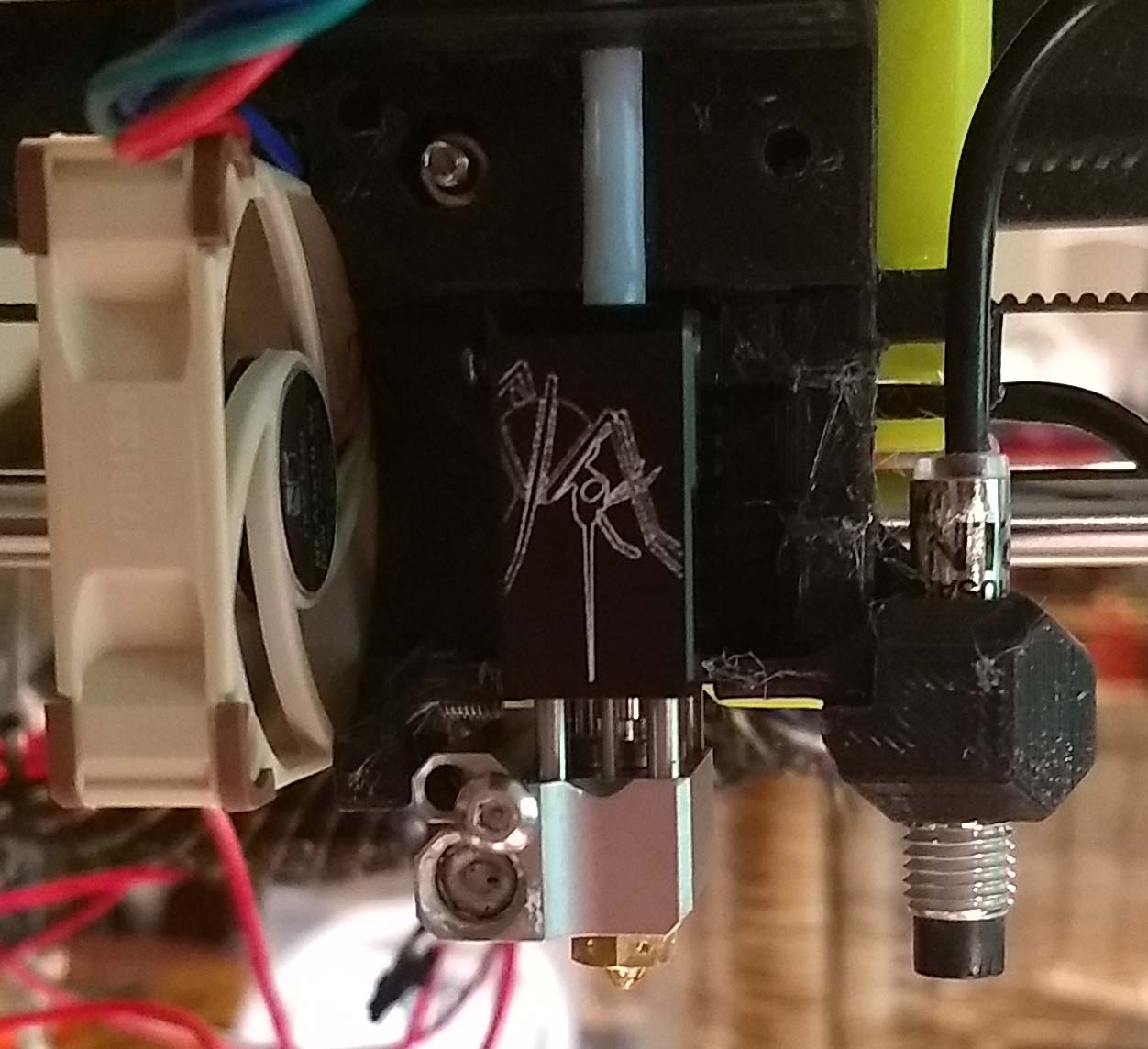

We decided to work with it on the MK3 vs. the MK2s in case we got far enough that we could heat it up to its designed temperature maximum. In short, we alternated between .25 and .40 nozzles and the PETG mount was more than sufficient to deal with the torque. First layer calibration went smooth on both and filament changing was pretty much the same as with the E3D V6. We started a few prints but time did not allow us to print enough to do a quality compare.

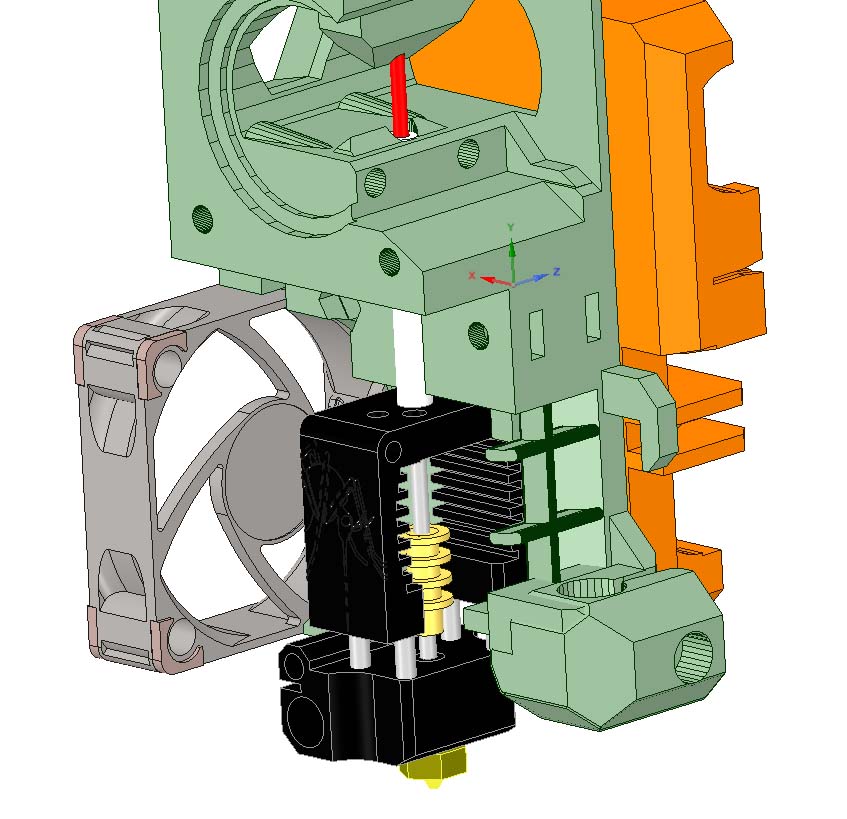

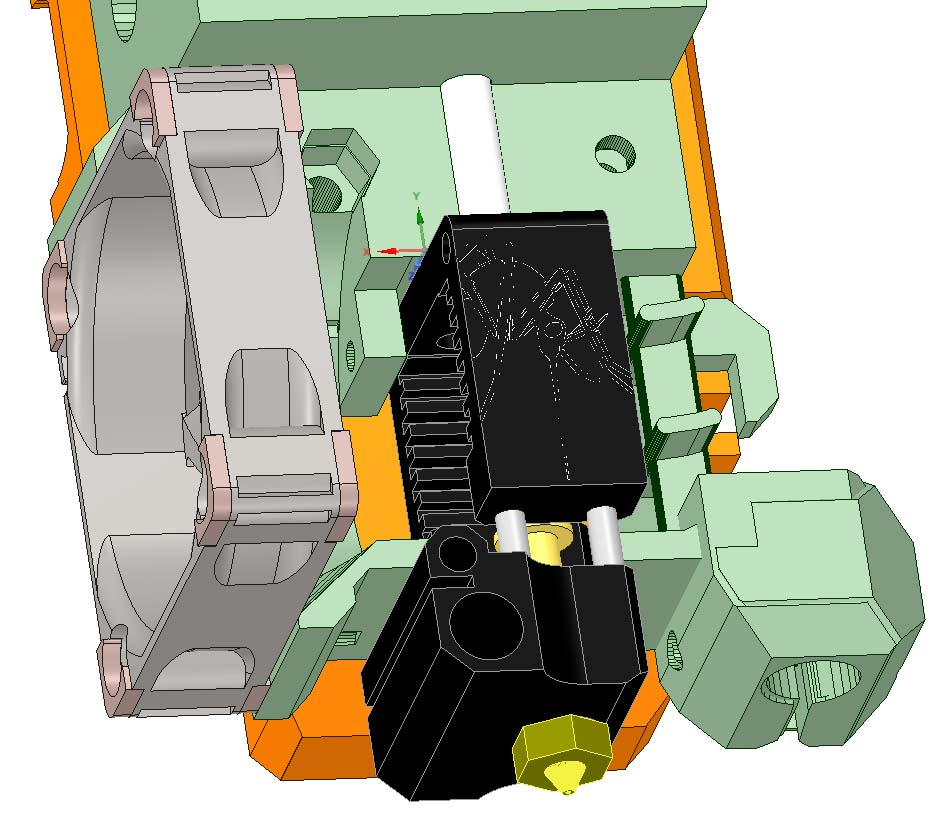

I will be getting a couple of these in a few weeks when they receive their new supply and then will be able to do the testing I want with the MK3 and an MK2s-MMU. Below are the CAD renderings of the hot end mounted and a picture of the actual mount. In all cases the extruder cover is removed in order to see the inner design.

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)

Re: Mosquito Hotend Testing

Any updates? How're things going?

Re: Mosquito Hotend Testing

Any updates? How're things going?

I am still awaiting two Mosquito's to document testing. They are CNC'd and are now resolving an issue with workholding to allow for parting off one piece from another. Current delivery is about 2 weeks out.

I have proceeded and fine tuned the MK3 mount, developed an MK2s-MMUv1 mount, and am currently working on an entirely new E-axis based on the Mosquito with no E3D-V6 'baggage'. All using existing electrics (fans, motor, Pinda). I am also working on several designs for a part cooling fan shroud as the current ones will not work based on the geometry of the Mosquito.

The quality, reliability and serviceability testing is my priority, otherwise, what's the point? Right? So I wait.

I will keep you informed as I progress. Jerry.

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)

Re: Mosquito Hotend Testing

Yes I'm interested in your testing progress also, meet the team from Slice Eng, at ERRF this past weekend, the design looked very intersting.

Mark

Re: Mosquito Hotend Testing

Okay. I received the first Mosquito last Monday and set it up for 12v as I wanted to test it on the Prusa MK2s-MMUv1 to see if it helped with the occasional jam. So far so good. I will continue to tax it through the week while I design the MK3 mount. That should time with my second Mosquito arriving later this week as I will set that one up for 24v. (Anyone know/have any PITA multicolor, sure to jam, models point me to them 😀 )

The pictures are of the MMU mount. I took the Prusa .scad files for the extruder body and extruder cover and merged them. I then just removed what I didn't need. The white part is the resulting one piece replacement. It mounts using the current three screws from the extruder back with captured nuts. The Mosquito mounts from the top using recessed screws included with the hotend. They are concealed by the Y-Splitter.

While the fan on the Mosquito does make some noise it is about half the db of the stock Prusa MK2 fan so I opted for that for a much cleaner install. I still need to work in the part cooling fan and shroud for those that want that but it was not a priority as I print PETG and do not use (need) them for what I print.

More to come and as it gels I will post on Thingiverse and Slice Engineering (Mosquito) sites.

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)

Re: Mosquito Hotend Testing

This is fantastic, I bought a Mosquito at ERRF for my MK3. I'll definitely give your mount a try once you post it to thingiverse.

Re: Mosquito Hotend Testing

First version is now on Thingiverse. As I did an MK3 mount first I will post there. Please make any comments on the MK3 forum post.

https://www.thingiverse.com/thing:2995464/files

Jerry.

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)

Re: Mosquito Hotend Testing

Pushing the fuses to extreme on the Mk2 (12V and 5A fuse for heat, motors & fans)

Slice Engineering is bringing a 50W heater

The stock 40W heater will take you well over 295 degrees. Their thermistor will probably not be OK with the firmware.

PeterI wanted 300C on the MK3, but it seems any dip over 300C causes the prusia to freak out, and immediately stop heating the hot end. I use Capricorn XS, which is designed for high temp filaments like Polycarbonate.

When I run the temperature pid calculator, it always alarms.. Unless I set print temp to something lower like 295C.

The same could be said for the heated bed. Up to around 110 to 115C, without a enclosure. I think its silly to have such restraints on the prusa.

War... War never changes.

Re: Mosquito Hotend Testing

I wanted 300C on the MK3

According to the Mk3 firmware, the max temp is 305, but the standard thermistor is really only good up to about 290. To do this, you really should consider upgrading to a PT100 and re-compile the firmware with the correct settings.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Mosquito Hotend Testing

According to the Mk3 firmware, the max temp is 305, but the standard thermistor is really only good up to about 290. To do this, you really should consider upgrading to a PT100 and re-compile the firmware with the correct settings.

Peter

Hmm, is there a guide for this? I thought the MK3 rambo board didn't support the PT100?

War... War never changes.

Re: Mosquito Hotend Testing

Hmm, is there a guide for this? I thought the MK3 rambo board didn't support the PT100?

Yes, it does, although you do have to change the defines in configuration_prusa.h and recompile the firmware.

At around line 25:

// Uncomment the below for the E3D PT100 temperature sensor (with or without PT100 Amplifier)

//#define E3D_PT100_EXTRUDER_WITH_AMP

//#define E3D_PT100_EXTRUDER_NO_AMP

//#define E3D_PT100_BED_WITH_AMP

//#define E3D_PT100_BED_NO_AMP

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Mosquito Hotend Testing

Hey guys,

I tried to install the Mosquito hotend w/ the slice engineering 450*c thermistor on my MK3. I don't think this thermistor is working with the stock firmware. What do I need to modify to make it work?

Best,

Kareem

Re: Mosquito Hotend Testing

As stated above, you will need to change the firmware and recompile if you want to use a thermistor other than the PRUSA supplied or E3D thermistor.

As far as the Slice Engineering thermistor, they have published the thermistor table on their site and there is a Youtube video showing you how to add these settings and recompile the firmware.

The video:

This is based on the same question I put to Slice Engineering and their response,"Our thermistor table is in Duet, and I have a ticket in to Marlin to get it in there. Chris Riley recently made a video on how to put it in Marlin yourself. I'm trying to get Prusa to bake it into their next firmware release, since they use a slightly modded version of Marlin."

Hope this helps. Jerry.

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)