What keeps the Z-Axis level?

I think some of my issues are the two sides of the Z-Axis do not appear to be at exactly the same level.

I have noticed you can turn one side independent of the other with a little force, which changes the skew of the bars the X-Axis traverses.

When the Z-Axis is at the top, the right is about 0.1mm lower than the left (measured with callipers). Also the screw on which it travels on the right seems slightly offset to the right.

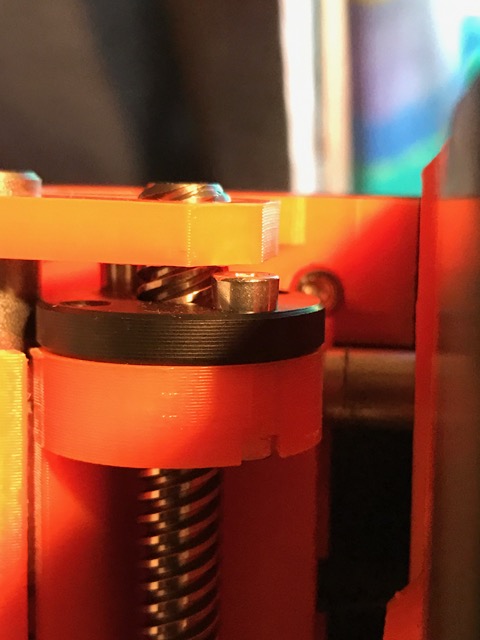

LEFT

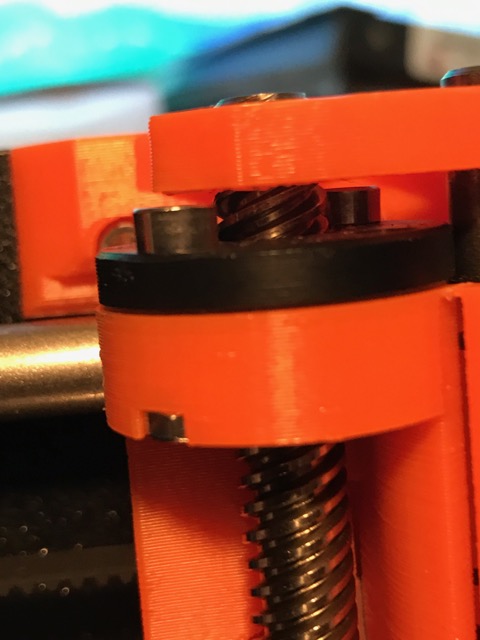

RIGHT

I'm not sure what could cause this. I think because of this I have been setting the head to close to the bed in order for both sides to stick.

If I set it to the right height for the right side of the bed, so the PLA is the correct shape, the left side doesn't stick at all.

I've tried changing the Mesh Bed Leveling to as much as -50 left, and +50 right, and the opposite values and that seems to make no difference at all, which is really odd.

Not sure where to go from here.

Re: What keeps the Z-Axis level?

First, measure the distance between heatbed and top edge of Z frame on left and right side of heatbed. Should be identical.

Second, check if X steel rods are parallel after you move Z axis all up until both steppers skip steps. Should be parallel.

Re: What keeps the Z-Axis level?

Not easy to measure, but from what I can tell both of these are correct.

However, the distance between the top x-axis bar and the top of the frame is not identical on the left and right sides.

I did a lot of changing of the bolts holding the Z frame last night and calibration reports the X/Y are perfectly perpendicular.

Re: What keeps the Z-Axis level?

Sorry I expressed it wrong. By "X steel rods are parallel" in second step I meant "X steel rods are parallel with Z frame".

Re: What keeps the Z-Axis level?

nothing keeps the Z axis level.

when the power is on, the Z motors are energised to keep the z axis where it is... but the printer has no idea where the z axis is, nor whether it is level or not.

if you are concerned about the z axis being out of square, you can use the settings option to move the Z axis up to the very top of travel, where it should bump into the top brackets.. and whichever side gets there first will stall and allow the other side to catch up...

when both sides stall, (Makes a clunking noise as the motor tries to run but isn't able to do so...

after this is complete. try the v2 calibration and adjust the squish using liveZ adjust...

once the calibration is complete, you should be good to go...

regards joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: What keeps the Z-Axis level?

Great thanks. That is clearer.

No the X-Axis is not perfectly parallel to the frame once it hits the stops at the top. As can be see in the picture, the gap is bigger on the right (by 0.1mm).

Bed Level Correct does not seem able to fix it. I think the issue may be a poorly printed motor holder on the tight hand Z-Axis. It didn't seem to fit fleshly to the motor. Z-Axis right side also makes some odd noises when you move the Z-Axis up.

Re: What keeps the Z-Axis level?

I think some of my issues are the two sides of the Z-Axis do not appear to be at exactly the same level.

I have noticed you can turn one side independent of the other with a little force, which changes the skew of the bars the X-Axis traverses.

When the Z-Axis is at the top, the right is about 0.1mm lower than the left (measured with callipers). Also the screw on which it travels on the right seems slightly offset to the right.

LEFT

RIGHT

I'm not sure what could cause this. I think because of this I have been setting the head to close to the bed in order for both sides to stick.

If I set it to the right height for the right side of the bed, so the PLA is the correct shape, the left side doesn't stick at all.

I've tried changing the Mesh Bed Leveling to as much as -50 left, and +50 right, and the opposite values and that seems to make no difference at all, which is really odd.

Not sure where to go from here.

First thing I see is I think you have the black threaded piece upside down. Check the manual.

Second, once you run the Z calibration it will stay that way as long as the power is on and you don't turn one of the screw rods.

I will generally run the Z calibration before a print if I suspect it might have gotten of at all. Simple and quick.

Re: What keeps the Z-Axis level?

The black threaded piece is the right way around, on the top. It cannot go anywhere else.

I believe I have resolved my issue now. Removing the right hand Z-Axis screw holder, twisting it left very slightly then re-tightening seems to have sorted it.

I printed the Prusa Logo and the Triceratops skull yesterday and they came out perfect. I am now printing a complex Cat print with lots of supports that previously failed on the first couple of layers, and now it is 40% in and looking perfect.

Re: What keeps the Z-Axis level?

The black threaded piece is the right way around, on the top. It cannot go anywhere else.

I believe I have resolved my issue now. Removing the right hand Z-Axis screw holder, twisting it left very slightly then re-tightening seems to have sorted it.

I printed the Prusa Logo and the Triceratops skull yesterday and they came out perfect. I am now printing a complex Cat print with lots of supports that previously failed on the first couple of layers, and now it is 40% in and looking perfect.

Sorry, misspoke on the direction of the part. It looked like the center nub was facing up not down. I had mine on backward at first and that is why I thought that.

Good to hear it is going now!!