Tall Prints Fail

Hey guys. My MK2 keeps failing on tall prints. The latest one happened on a cylinder around the 130mm mark. When I found it, it was off the build plate and there is a blob on the top where the fail started and then just a stringy mess on the build plate after that. It was printed next to a smaller cylinder with the same diameter which completed and was very secure to the build plate.

I had a different print do the same thing around a similar height a few weeks ago. It prints perfectly until it gets to this height.

Any ideas on what could be causing this? Is the extruder or extruder cable bundle knocking it off the build plate? Thanks!

Re: Tall Prints Fail

Insufficiant surface contact with heatbed?

Try adding a brim.

Try using Zhop. To reduce the chances of collision between nozzle and part being printed?

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Tall Prints Fail

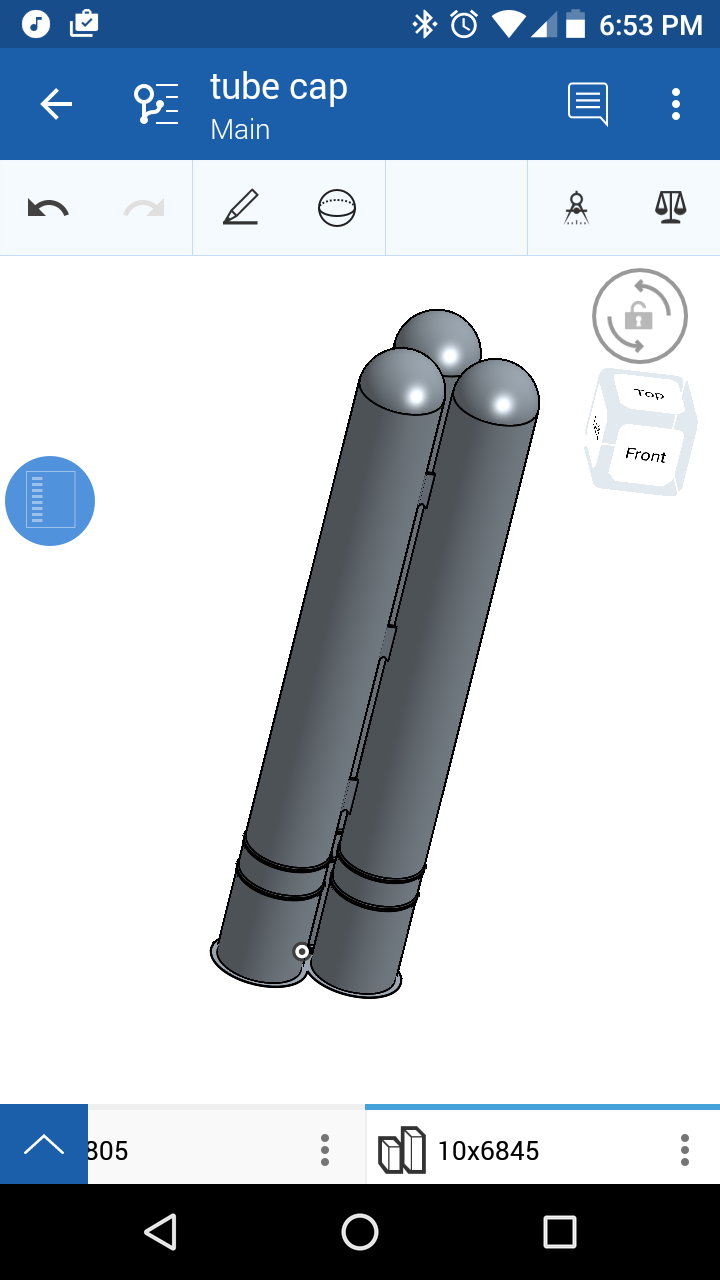

I print stuff like this in batches. I create 3 of them, add a manual brim, then also create bridges/braces spaced between them so they reinforce each other. They can be snipped off afterwards. I also use glue stick.

These were about 180mm tall.

Your description also indicates there may be something mechanically wrong with your setup but without pictures its anyone's guess.

Re: Tall Prints Fail

The print that failed a couple weeks ago had a large base and was still very secure to the build plate despite the failure. I've included some pictures of it. The only thing missing from the pictures is the stringy mess of filament that was laying on and around the build plate. After this, I printed the rest of the legs a little before the failure point and they printed fine. It's like my printer just can't handle anything above the ~120mm mark.

Re: Tall Prints Fail

did you check your extruder cable harness ? it looks as if your cable is hanging a bit downwards behind the extruder and the other end is not attached "upwards" at the rambo cover.

maybe above 120mm it interferes with the print which causes the mess then.

at my genuine i3 mk2 kit i've attached a few rubber bands between the cable trunk and the top of the frame (@ spool holder) which secures that there is no interference with the extruder wiring loom.

dem inscheniör is' nix zu schwör...

Re: Tall Prints Fail

I did check the cable harness. I put my extruder in the position around the 120mm mark and it seems like there's no way it caused the cylinder to fail. It could possibly have played a role in my first fail since that had a lot more travel in the y-axis. It'll work on getting it higher from the build plate and more secure.

Does anyone think the blob on my cylinder where the fail started indicate what could have happened? Would that have still occurred if it turned out the cylinder wasn't adhered to the bed as I thought and just fell over?

Re: Tall Prints Fail

...

Does anyone think the blob on my cylinder where the fail started indicate what could have happened? Would that have still occurred if it turned out the cylinder wasn't adhered to the bed as I thought and just fell over?

nearly impossible to tell without a (timelapse)video that was recorded during the print.

dem inscheniör is' nix zu schwör...

Re: Tall Prints Fail

Looking at the images from the tubes and the headphone rest, you could have a few possibilities.

1) Based on how the headphone rest looks, it appears that you may be using ABS and as you get up to the thinner parts of the print, your ABS isn't able to cool down quickly enough and starts warping and not holding shape. This happens with ABS and you can take different approaches to resolve the problem. If you're using Slic3r, you can use the auto-cooling feature and tell it to turn the fan on when needed. There are some side effects with its use, but its the easiest way to fix that problem. Other way to work around it is to slow the print down once you reach a certain height. Just spin the dial CCW on the front to make a live change during print to slow the print down.

2) Based on the tubes picture, you could be having a problem with your axis's binding or not moving at all. The reason I am saying this is because you have a large blob on the print and then you have extruded filament attached to it. Not certain that is the case, but that is how I see it based on the picture.

As JeffJordan has said, if you can get a video of when it occurs, it would make it so much easier to determine root cause. A Timelapse may not catch it though as its a mixture of jpg pic grabs over time. So when it happens, it may not have grabbed that frame. If your smarphone has slo-mo setting and you know the time frame it happens, you can set up a slo-mo with your camera during that timeframe and then would have a much better video to see specifics of what happens.

good luck on finding the cause...

Re: Tall Prints Fail

Looking at the images from the tubes and the headphone rest, you could have a few possibilities.

1) Based on how the headphone rest looks, it appears that you may be using ABS and as you get up to the thinner parts of the print, your ABS isn't able to cool down quickly enough and starts warping and not holding shape. This happens with ABS and you can take different approaches to resolve the problem. If you're using Slic3r, you can use the auto-cooling feature and tell it to turn the fan on when needed. There are some side effects with its use, but its the easiest way to fix that problem. Other way to work around it is to slow the print down once you reach a certain height. Just spin the dial CCW on the front to make a live change during print to slow the print down.

2) Based on the tubes picture, you could be having a problem with your axis's binding or not moving at all. The reason I am saying this is because you have a large blob on the print and then you have extruded filament attached to it. Not certain that is the case, but that is how I see it based on the picture.

As JeffJordan has said, if you can get a video of when it occurs, it would make it so much easier to determine root cause. A Timelapse may not catch it though as its a mixture of jpg pic grabs over time. So when it happens, it may not have grabbed that frame. If your smarphone has slo-mo setting and you know the time frame it happens, you can set up a slo-mo with your camera during that timeframe and then would have a much better video to see specifics of what happens.

good luck on finding the cause...

Both of the prints were done using E-sun PLA+. I don't know if this material would have the same problem as the ABS you mentioned.

If it was the axis binding up or extruder not moving, how would I go about fixing that?

I'm reprinting the cylinder right now with the same settings. I'm planning on setting up a recording when it gets closer to the 120mm mark.

Re: Tall Prints Fail

I haven't used eSun PLA+, but it shouldn't be much different than their normal PLA.

As for binding or extruder failure, those would be handled differently. Binding would be to look at which axis is binding and then see what is causing it. If the extruder stops working at that point, then I would look into wiring issues to the extruder.

Re: Tall Prints Fail

I was just looking at my failed cylinder when I noticed that the top portion near the failure is slightly shifted. I didn't even notice it until now. I tried to get a picture of it the best I could. I'm assuming this and the failure are related. Any ideas on the cause? Thanks!