Rigid.Ink PLA Plus Print Settings Guidance and Benchy issues

Hey all,

I just picked up some Rigid.Ink PLA Plus in their recent sale and I'm just dialling in my printer to make use of it. I tried a Benchy at 0.10mm layer height with the recommended base settings (220/55) using Slic3r and the result was this:

I've tried to identify the name of this type of print artifact to try and troubleshoot, but I'm struggling to find something that fits. I suspect it's Oozing, but perhaps someone here can help ID the issue?

I watched Thomas Sanladerer's Filaween video on it and tried his hotter settings (235/60, 85-100% fan), to the same effect. Conversely, I tried the lower temp settings discussed in this thread: https://shop.prusa3d.com/forum/print-tips-slic3r-settings-kisslicer-model-repair--f12/rigid-ink-pla-plus-settings-t3725.html , again with no luck (exact same result).

I'm currently trying a hot profile (240/55, 100% fan) with increased retraction length of 0.9mm but that's already showing signs of the oozing/rough surface of the ship's hull.

Any thoughts welcome!

Re: Rigid.Ink PLA Plus Print Settings Guidance and Benchy issues

maybe cooler than first print?

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Rigid.Ink PLA Plus Print Settings Guidance and Benchy issues

I attempted a run with 210/55, 85-100 fan and the result was identical, only with worse layer adhesion strength (the part was visually identical but snapped in half easily).

I have a feeling it has to do with retraction length and speed; is there a general rule of thumb for tweaking that?

Jim

Re: Rigid.Ink PLA Plus Print Settings Guidance and Benchy issues

If you visit RigidInk's site you will see their recommendations.

https://rigid.ink/pages/filament-comparison-guide

Their PLA is quite pure and has a lower melt temperatures.

I use 180 (190 first layer) and 45 deg C bed and get good results.

Neale.

Re: Rigid.Ink PLA Plus Print Settings Guidance and Benchy issues

I have used quite a bit of Rigid ink and had some fantastic results It is really good stuff. As outlined above though you have to print significantly cooler than other cheaper Filaments.

180/40 works best for me.

Re: Rigid.Ink PLA Plus Print Settings Guidance and Benchy issues

Hey all - thanks for the suggestions; I wanted to make sure it was clear I'm talking about Rigid.Ink PLA Plus+, not their regular PLA (which is my favourite filament and I get excellent performance from).

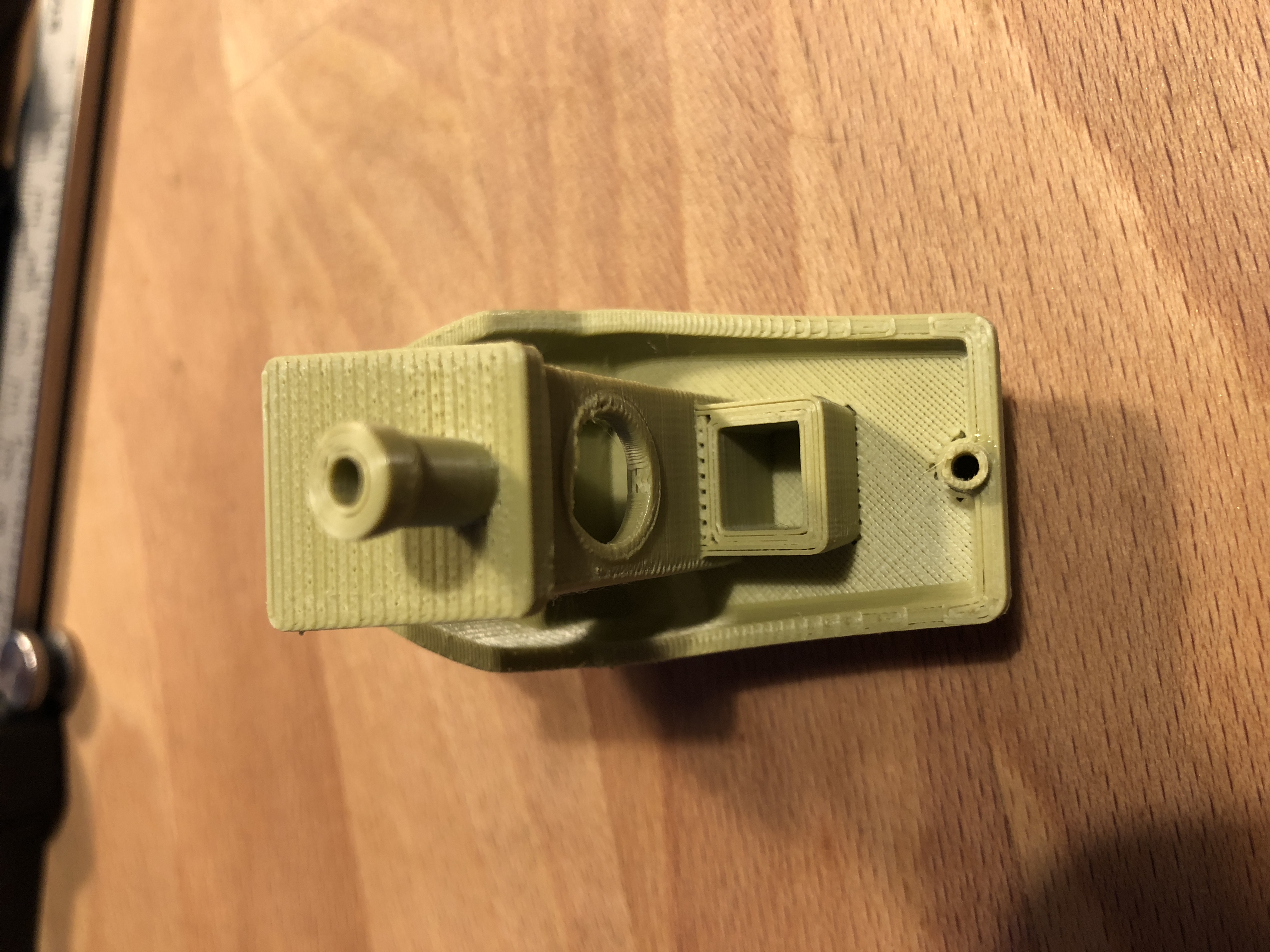

I gave it another full run with the recommended Rigid.Ink settings, but I used the Prusa Tune settings to reduce the print speed to 50% after the first few mm. You can see a marked improvement in the surface finish after the first 4mm or so (when I tweaked the tune setting mid-print):

I found a discussion about similar issues with Benchy's and really any print with overhangs on the Ultimaker forums ( https://community.ultimaker.com/topic/16558-rough-texture-on-lower-rounded-edges/ ) which helped me troubleshoot further. Here's a print with recommended settings, but at 0.15mm layer depth - almost no rough patches:

I think the bottom line is that Rigid.Ink PLA Plus+ just doesn't print well at lower layer heights due to it's temperature sensitivity and consistency. At lower temperatures, the layer adhesion is just way too low to be useful (especially for a filament that is supposed to be more rugged than PLA!).

Speaking of which, I just printed a benchy with Rigid.Ink PLA in black - came out absolutely perfect, and much more physically strong than the PLA Plus+:

All in all I'm just very disappointed in the PLA Plus+. Thanks for the comments everyone!

Jim

Re: Rigid.Ink PLA Plus Print Settings Guidance and Benchy issues

I also tried the PLA+ some time ago. Interesting material, but very weak and soft.

https://shop.prusa3d.com/forum/hall-of-fame-best-3d-prints-f15/voronoi-teddybear-t3812.html

But I don't have such problems you described. I know this problem, it's caused by insufficient cooling. Try to cool more or optimize your cooling fan duct.

Thomas

Re: Rigid.Ink PLA Plus Print Settings Guidance and Benchy issues

You might want to reduce the temperature and also turn the object so the bow is front instead of the side. Is the other side of the benchy better or are they both the same?

Re: Rigid.Ink PLA Plus Print Settings Guidance and Benchy issues

You might want to reduce the temperature and also turn the object so the bow is front instead of the side. Is the other side of the benchy better or are they both the same?

Great question - what is very interesting is that it ISN'T identical on both sides - the side facing front usually has quite a good surface finish up until the bow overhang, where it starts getting rough. On the other side however, it is rough all the way along. When I saw that, I thought along the same lines you did (and was also discussed on the Ultimaker forums) - that it might be a cooling issue due to the placement and efficacy of the Prusa cooling duct. I did a test with it rotated 90 degrees (so the bow faced front and so closest to the cooling fan) - identical results, including the asymmetrical roughness on the sides of the ship.

At that point I thought that a different slicer might improve things as perhaps Slic3r's pathing logic isn't good for aggressive overhangs or something - I loaded it up in Cura and tried a few bracketed settings (recommended temps, high temp, low temp, etc) - all more or less the same. Slightly better surface finish on overhangs, but I'd say worse overall precision of the print (sloppy bridges, the words on the benchy were a mess, etc).

I've been in contact with Rigid.Ink's support team re: this and they provided the following settings to try for troubleshooting:

I would suggest you print on a bed at no more than 45°C, at 205°C and no more than 30mm/s (25mm/s better and maybe a 80% reduction for layers that take less than 10 seconds - like the smoke stack) for a standard size #3Benchy.

Full fans from after layer 1.

20% infill overlap maximum.

Extrusion Multiplier x0.9-x0.95

For a 0.4mm nozzle, the extrusion width 0.48

These resulted in the following print (that just this second finished):

Structural integrity was still very poor - I was able to snap the benchy's top section off with little effort - the Black Rigid.Ink PLA version I showed above I can't do that without using extreme force bare-handed.

I'll update the thread as I work through solutions with the support team.

Thanks,

Jim

Re: Rigid.Ink PLA Plus Print Settings Guidance and Benchy issues

Any updates? I've been having similar although not identical issues with PLA PLUS from rigid ink. I get very poor performance on some overhangs, but fine on others - it seems to be sensitive to overhangs with corners. Strength seems fine though.

I'm thinking of trying different retraction settings.

Interesting what rigidink have told you to try.

Re: Rigid.Ink PLA Plus Print Settings Guidance and Benchy issues

Hi Folks,

I'm Susan from rigid.ink.

I've been contacted by Jim.h and am running some tests for him at the moment.

Please bear with me as I am currently on holiday and am doing this at home on my CR10. (MK3+MMU on order since January!)

I am using Jim's settings for each print to best match the problem and so it takes just over 3 hours per Benchy - it might take me a couple of days to get back with any findings. I just thought I would let you guys know.

Susi.

Joan - finally I found you! I think. I would PM you, but as this is my first post - I cannot.

I tried every variation I could think on the email I wrote down on the card at TCT - the blasted pen smudged everywhere, and I could not read it!

I am so sorry. You must have thought me so rude!

If it was you, can you PM me if you still want to talk?

Thank you.

Re: Rigid.Ink PLA Plus Print Settings Guidance and Benchy issues

Any updates? I've been having similar although not identical issues with PLA PLUS from rigid ink. I get very poor performance on some overhangs, but fine on others - it seems to be sensitive to overhangs with corners. Strength seems fine though.

I'm thinking of trying different retraction settings.

Interesting what rigidink have told you to try.

Interesting - Susan has been working with me on a few theories and tests; I've found that a print temp of 250/50 at a layer height of 0.2mm with an extrusion multiplier of 1.1x results in "ok" strength prints with reasonable surface finish (definitely without any of the surface roughness in my photos). So far, compared to the stock PLA, the PLA Plus worse in every regard though, and the layer adhesion issue is really causing me a headache.

Susan also appears to have gotten some of the scaly/rough finish on her test prints. What settings are you using?

Jim

Re: Rigid.Ink PLA Plus Print Settings Guidance and Benchy issues

Hi Folks,

I'm Susan from rigid.ink.

I've been contacted by Jim.h and am running some tests for him at the moment.

Think our names are too similar and it got confusing here 🙂