removing sheared off nozzle?

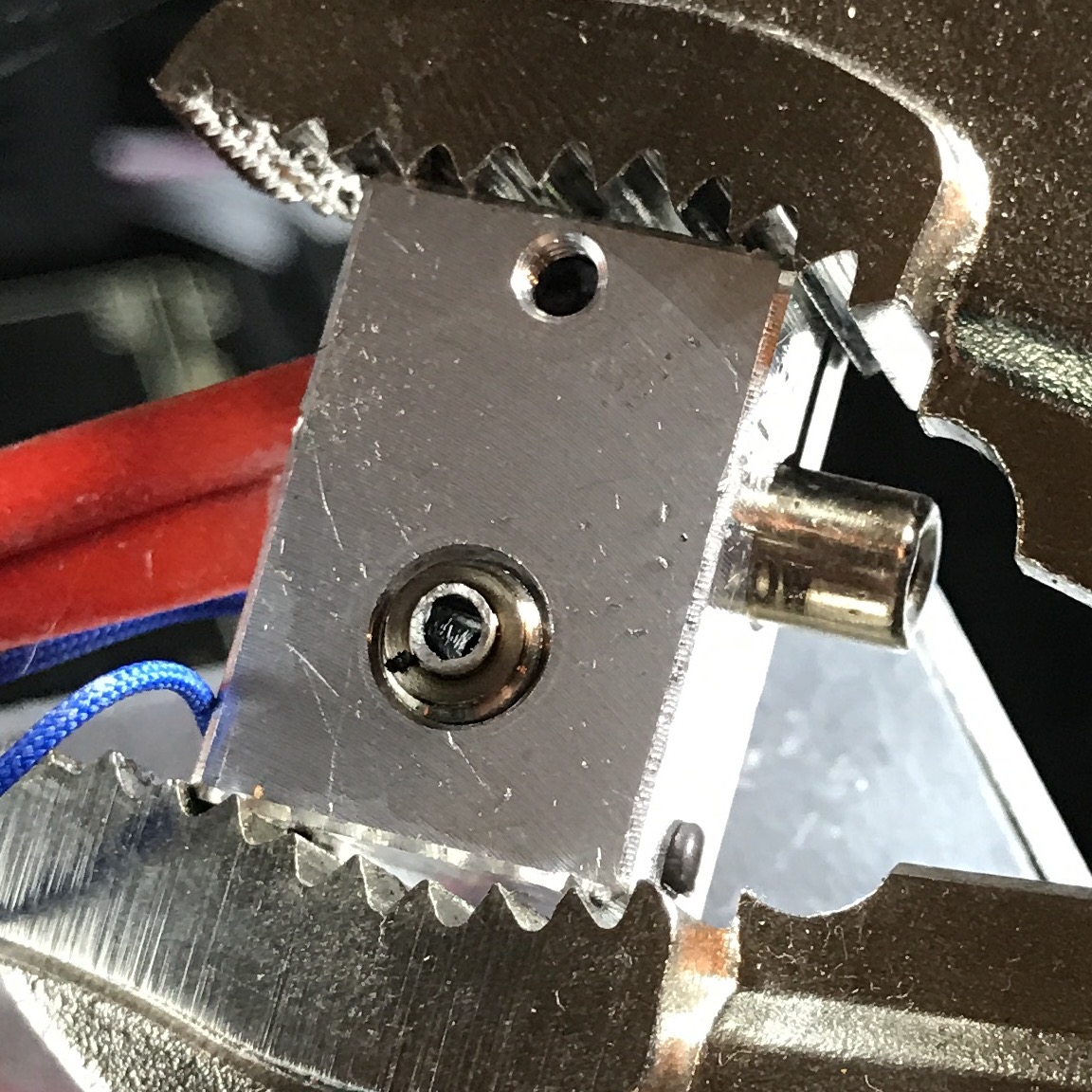

Ok, lemme start out by admitting I F'd up. Big time. I forgot to heat the block before attempting to remove the nozzle... sheared the brass right off flush with the bottom of the heater block.

So now I'm trying to figure out how to get the remains of the nozzle out of the heater block? Or for that matter how to get the heat break out without damaging it?

At this point I have the heater block, the heat break and (half) the nozzle in one unit. Everything else is removed and sitting to the side.

I was able to separate the heat sink from the heat break by applying some heat with a heat gun. That actually made removing the heat sink a piece of cake. Once that was off, I flipped the heat gun to high power and finally managed to remove the clog that lead to this whole disassembly in the first place... if only I hadn't tried to remove the nozzle I would have just re-assembled and moved on.

So far I've attempted to use a philips screw driver after heating the block/nozzle because a few folks said that worked for them, it's not working for me. I've attempted to use a tap out (broken screw remover), again after heating them up with the heat gun, again it's not budging. Any other ideas?

Re: removing sheared off nozzle?

Id you use the heater to heat the block to 250 degrees, hold the block with an adjustable wrench and the heat break with end cutters:

You should be able to remove the heat break from the block.

What's left of the nozzle should unscrew quite easily.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: removing sheared off nozzle?

oooh, that's a very different shape than my flush cutters.... I love the looks of that, will have to go wander to tool aisle at the hardware store to see if they have something more like that.

Everyone says the nozzle should be easy to remove... it hasn't been. but I think you've added a key item... the heat break has to come out first. Thanks!

Re: removing sheared off nozzle?

but I think you've added a key item... the heat break has to come out first. Thanks!

Only because you have broken the nozzle and cannot get a decent purchase on it.

Ordinarily, use the correct size spanner for the nozzle and heat to 250+ and it will come out easy enough.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: removing sheared off nozzle?

Just to post the follow up in case anyone else stumbles over this thread.

I heated the block back up to 250ºC, let it set there for a while, then gripped the block with a pair of grips, and the top of the heat break with my needle nose pliers and gave a very light turn... focusing on keeping the heat break straight up and down, no side to side motion.

Well, on the third attempt to turn it, it too sheared off.

So now I have a sheared off nozzle AND heat break!

To add insult to injury... apparently while the heater block was at temp, a bit too much force was put on the side of the block, and the metal deformed and pinned the thermistor in place.

#FML

Re: removing sheared off nozzle?

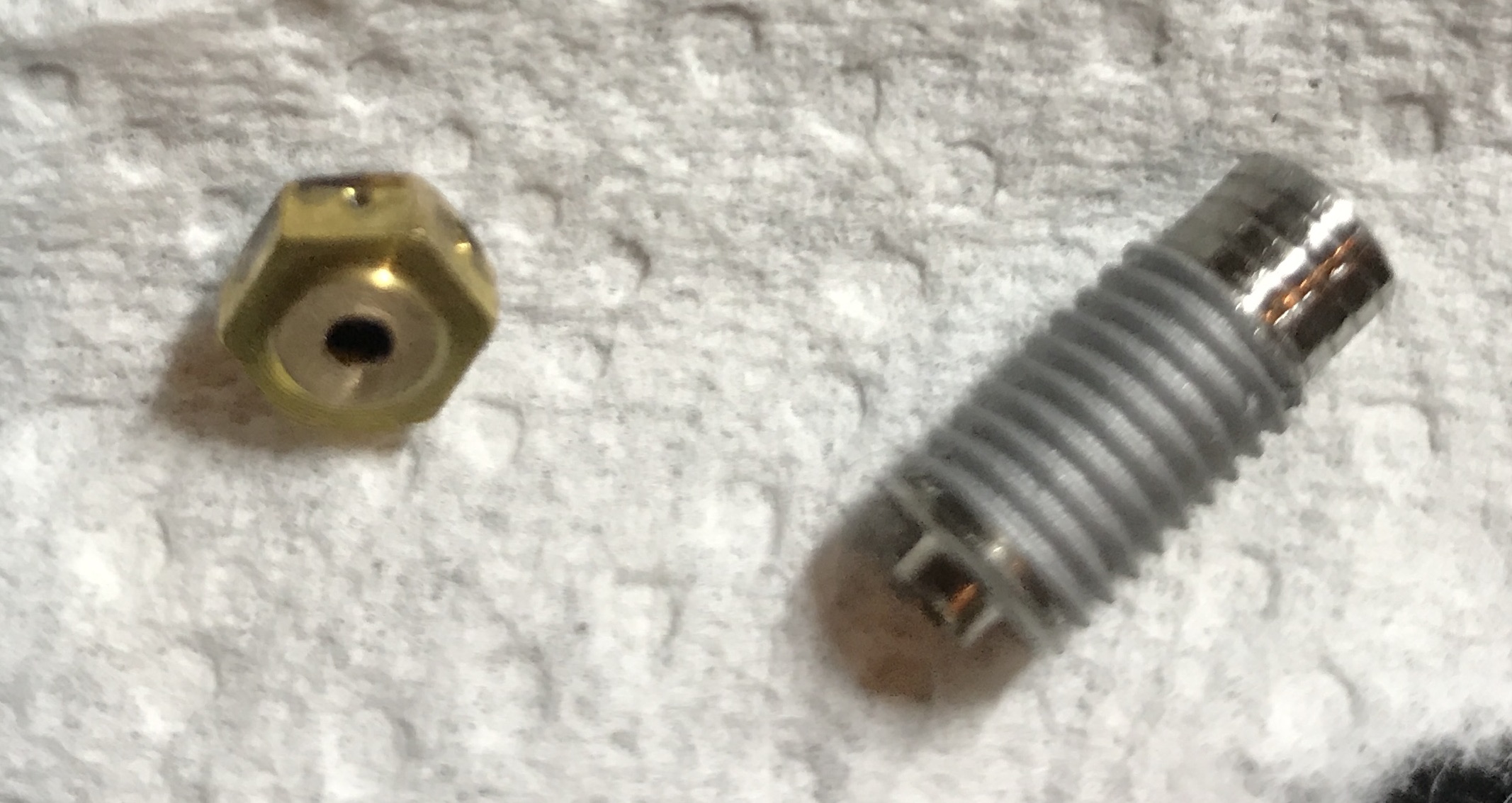

Looks like you need some spares then. If you're in the U.K. Then get them direct from e3d.

Re: removing sheared off nozzle?

Yeah. I've got an order in to MatterHackers, who are just a few hours south of me... about $85 to rebuild it all. Guess that means I really should figure out how I got a lump of melted filament in the heat break... so I can NOT do all this again.

Re: removing sheared off nozzle?

Sorry that you have had this issue.

Best way to remove filament stuck in the heat break? Remove the extruder fan, heat the extruder to 240 degrees, wait a few minutes while manually pushing filament from the top. Without the fan, the heat creep will melt the blocked filament and allow you to push it through.

But you will still have to change nozzles occasionally. So I guess this is a good exercise. (just trying to find any benefits from this...)

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: removing sheared off nozzle?

Best way to remove filament stuck in the heat break? Remove the extruder fan, heat the extruder to 240 degrees, wait a few minutes while manually pushing filament from the top. Without the fan, the heat creep will melt the blocked filament and allow you to push it through.

hmm... I was under the impression that doing so would be bad for the plastic PTFE tube retention clip at the top of the heatsink. I understood the heat sink needed to come off before I did anything like that.

But you will still have to change nozzles occasionally. So I guess this is a good exercise. (just trying to find any benefits from this...)

HAHA, yeah... I've been trying to find the silver lining too. This would have been the 3rd time I'd removed the nozzle, so as I said back in the opening... I F'd up. I knew it as soon as it happened.

Re: removing sheared off nozzle?

Best way to remove filament stuck in the heat break? Remove the extruder fan, heat the extruder to 240 degrees, wait a few minutes while manually pushing filament from the top. Without the fan, the heat creep will melt the blocked filament and allow you to push it through.

hmm... I was under the impression that doing so would be bad for the plastic PTFE tube retention clip at the top of the heatsink. I understood the heat sink needed to come off before I did anything like that.

No it will be fine.

The PTFE in the heat break is OK up to 255 degrees and the plastic ring at the top of the heat sink will hardly heat up at all.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…