Prusa I3 MK2 Bed Warming Slowly (Bed Thermal Runaway FIXED)

I've had my Prusa I3 MK2 for around 8 months and it's been a great printer. I've ran through the extruder about 8-10 kg and I noticed this past month it seemed like the print bed was taking longer to heat up. Around 2 weeks ago my printer gave me an error which was Bed Thermal Runaway. I noticed my print ended early so I redid the print and it happened within 30 minutes. I ended up watching my printer and it seemed that the bed temp would hit the desired target but within 5 minutes the heat bed wasn't able to hold the temperature. I noticed the red LED bed light would occasionally go off even when the bed was 5 or more Celsius below my desired target.

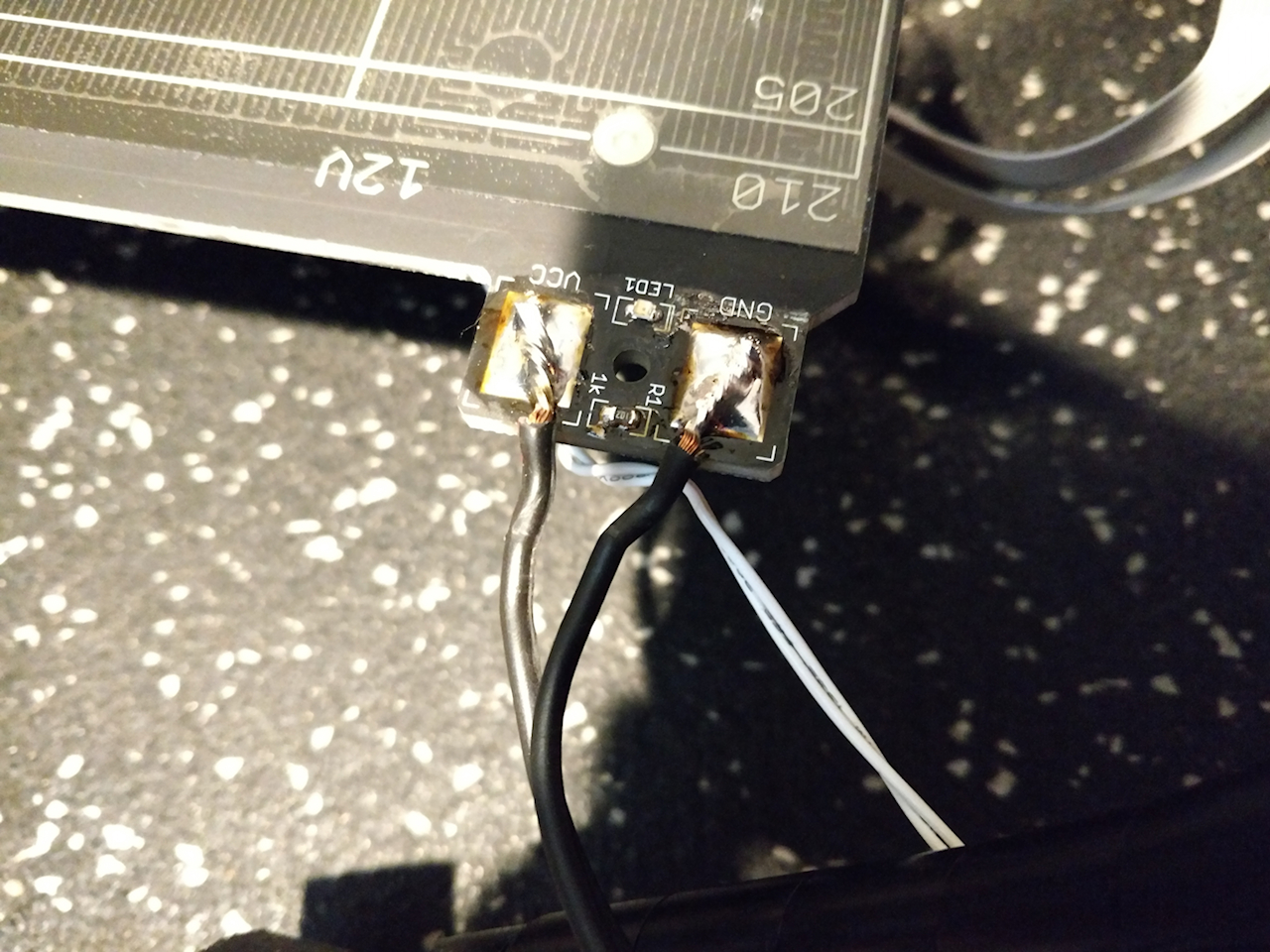

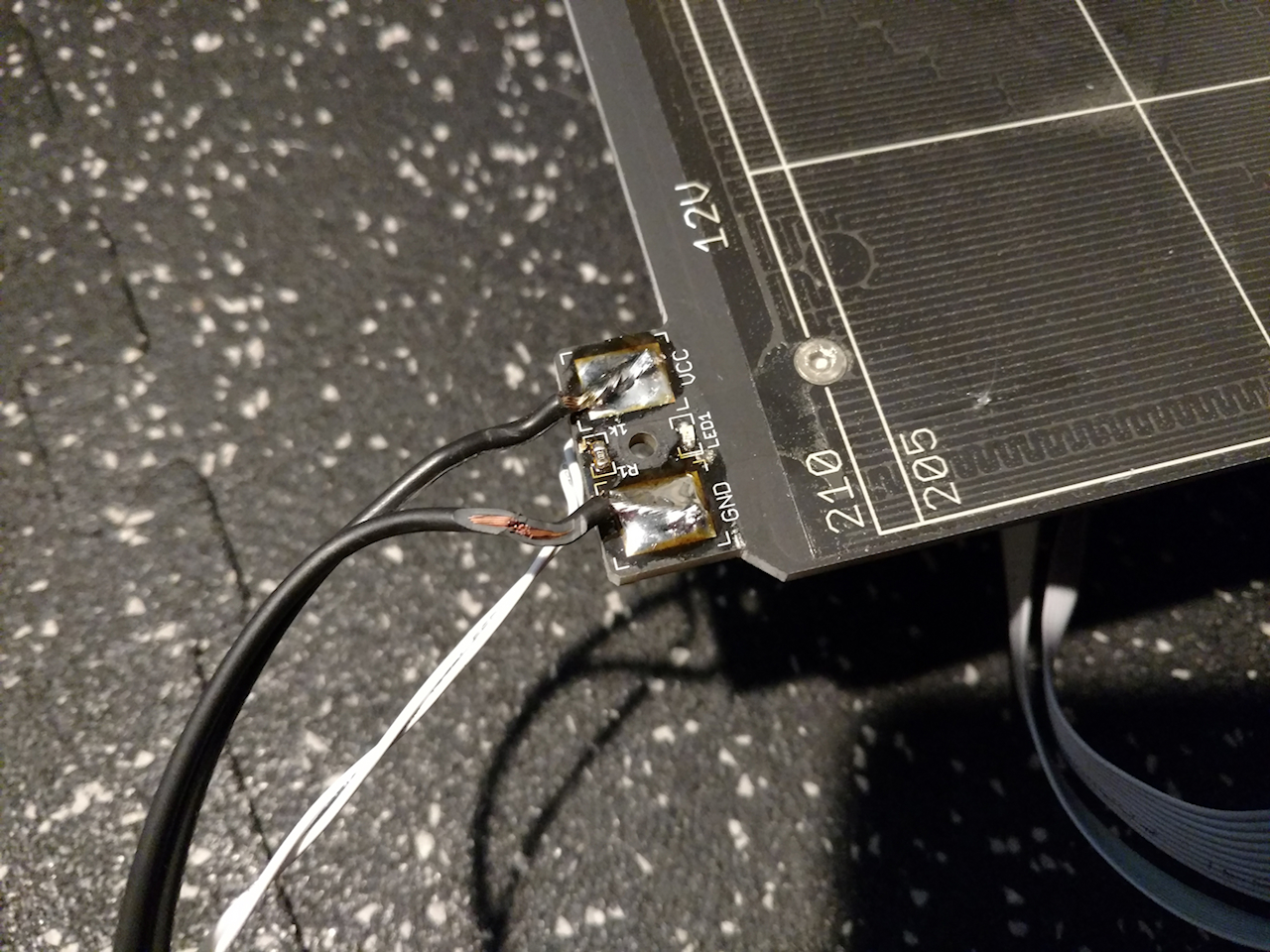

This led me to inspect the wiring from the bed to the Rambo. The copper wire actually broke inside the insulation from being fatigued over time. I diagnosed this by simply hitting preheat on my printer and started bending the wire and i was able to make the print bed red led go on and off. An ohms meter I also used but figured some might not have one so this is an easy way to help diagnose the problem. I recall during assembly I didn't like how the wire was soldered. I removed the insulation of the wire so you all could see the damage. A simple fix and the printer is back up and running.

I figure this post will help others in diagnosing possibly their issue.

Damaged Wire

Insulation Removed

Fixed (Flux, Solder, and Cleaned)

Re: Prusa I3 MK2 Bed Warming Slowly (Bed Thermal Runaway FIXED)

Hello Jeff!

I just thought I could complement this excellent post with a tip:

If you would like a long service life of a wire - use one with copper strands that have a small diameter (preferably with as small diameter of the strands as possible e.g. 0.07 mm). Then you will benefit of a higher fatigue limit with repeated bending of the cable.

/Henrik

Re: Prusa I3 MK2 Bed Warming Slowly (Bed Thermal Runaway FIXED)

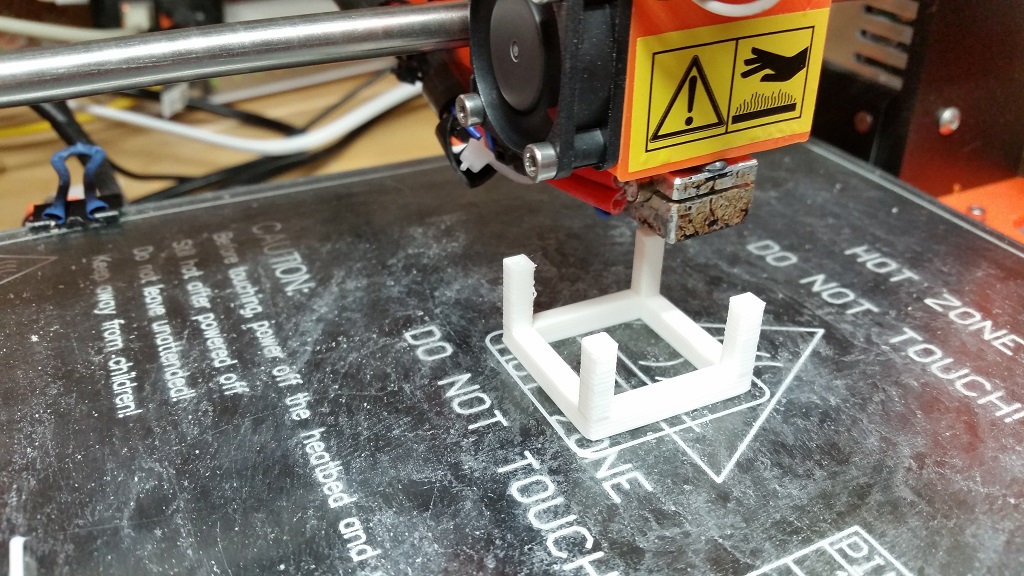

Thank you for making this post! I've had my printer for two weeks and I ended up having the exact same problem! Mine was a little more obvious once I took the 3D printed solder joint cover off. (Fatigue of a 15 hour 200x100mm print caused it)