Problems with new printer: Broken ties, failing/clogging tree frog

Got my assembled Prusa i3 MK2 a little over a week ago after a 3 month wait. Unfortunately, I'm having a few problems, though some I believe are just a matter of figuring out the right slicer settings for some of my objects; I won't worry about those here. Note that I did the "assembled" calibration flow from the manual before printing anything.

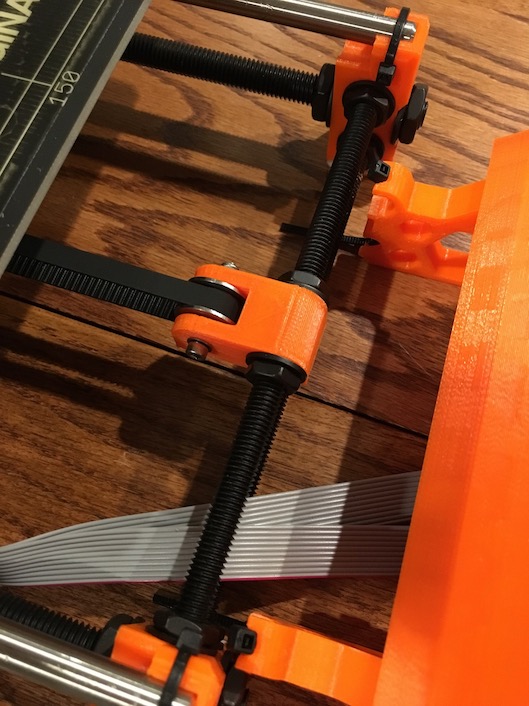

First, when I unboxed the printer, I noticed the zip ties that are supposed to hold the LCD panel in place were broken. I'm assuming the panel is supposed to be secured to the two large bolts in front. Is this a problem that they're not? The ribbon cable looks fine so I'm assuming it's not an issue. It does make me wonder if there are other problems elsewhere I'm not seeing, though nothing obvious comes to mind looking over the rest of the printer.

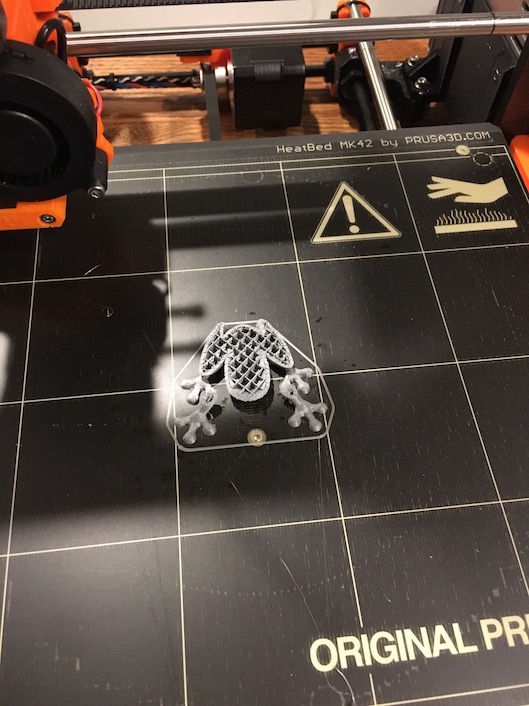

Second, when I try to print the tree frog sample object that came on the SD card, it fails every time and I end up with a clogged nozzle. It prints a small amount and then keeps trying to print but nothing comes out of the nozzle. [TODO: insert picture] I end up having to heat the head and yank the filament back out (is there a better way to do this?). I'm using the Prusa filament that came with the printer, and the other objects I've tried from the SD card have been fine (dragon, dog, gear thing, Prusa logo, Batman logo), but three times I've tried the frog and three times the print has failed and clogged the extruder. I'm guessing maybe this is because the frog was sliced at 0.05mm layer height (the other objects have all been 0.1mm or more). I don't really have a need to print smaller than 0.1mm, but even so 0.05mm should work. Any suggestions? I'm hoping I don't need to disassemble the print head and clean out the nozzle within a week after getting the printer.

Thanks!

Re: Problems with new printer: Broken ties, failing/clogging tree frog

Hi,

Concerning your frog print : if I am not mistaken, you need a 0.25mm nozzle to print 0,05 mm layer height. Thus I think that what you are experiencing is normal.

Re: Problems with new printer: Broken ties, failing/clogging tree frog

That LCD should simply snap back on. No biggie. I might eben hold without cable ties, i remember when i put my kit together, i needed brute force to the git it on there. See Steps 9 and 10 here: http://manual.prusa3d.com/Guide/6.+LCD+assembly/300

With respect to the treefrog print. Not sure, but i remember other people had issues here on the forum with it as well, usually right around the legs part shown in your picture is where it seems to fail often. I had printed an army of treefrogs back when i got my first printer, so i never tried it on the Prusa.

With respect to yanking the filament out, this is actually not the worst idea. Or in other words: An easy and yet effective way to clean a nozzle from the inside is to do cold pulls, I use it as preventive maintenance whenever I change filament spools. Here's 2 videos that explain it better: or

Re: Problems with new printer: Broken ties, failing/clogging tree frog

All Prusa-supplied GCode, including the tree frog is for a 0.4mm nozzle - this nozzle can be used for all layer heights up to 75 or 80% of nozzle diameter without issue.

Regarding the blockage during printing, there are a few possibilities including, but not limited to:

1. You have an older model with incorrect retraction settings (which should now be 0.8mm or less). Download the driver package and test the same model within that.

2. Your PTFE tube doesn't connect internally with the heat break.

3. You have incorrect tension on the extruder feed pulley - too tight or too loose

4. Your filament spool is not well wound, and not feeding smoothly.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Problems with new printer: Broken ties, failing/clogging tree frog

That LCD should simply snap back on. No biggie. I might eben hold without cable ties, i remember when i put my kit together, i needed brute force to the git it on there. See Steps 9 and 10 here: http://manual.prusa3d.com/Guide/6.+LCD+assembly/300

I initially tried to snap it back on, but it did seem like it would take a lot. I'll check out the link.

With respect to the treefrog print. Not sure, but i remember other people had issues here on the forum with it as well, usually right around the legs part shown in your picture is where it seems to fail often. I had printed an army of treefrogs back when i got my first printer, so i never tried it on the Prusa.

OK; I'll search the the forum for other threads about it.

With respect to yanking the filament out, this is actually not the worst idea. Or in other words: An easy and yet effective way to clean a nozzle from the inside is to do cold pulls, I use it as preventive maintenance whenever I change filament spools. Here's 2 videos that explain it better: or

I've seen the second one, I'll take a look at the first.

Thanks for your help!

Re: Problems with new printer: Broken ties, failing/clogging tree frog

1. You have an older model with incorrect retraction settings (which should now be 0.8mm or less). Download the driver package and test the same model within that.

It was shipped a couple weeks ago, so it should be an MK2S.

2. Your PTFE tube doesn't connect internally with the heat break.

3. You have incorrect tension on the extruder feed pulley - too tight or too loose

4. Your filament spool is not well wound, and not feeding smoothly.

If any of these were the case, would it affect the other models or just the treefrog? Marvin, the dog, and the dragon (among others) print fine.

In any case, thanks!