Problems printing with PETG after MK2 upgrade

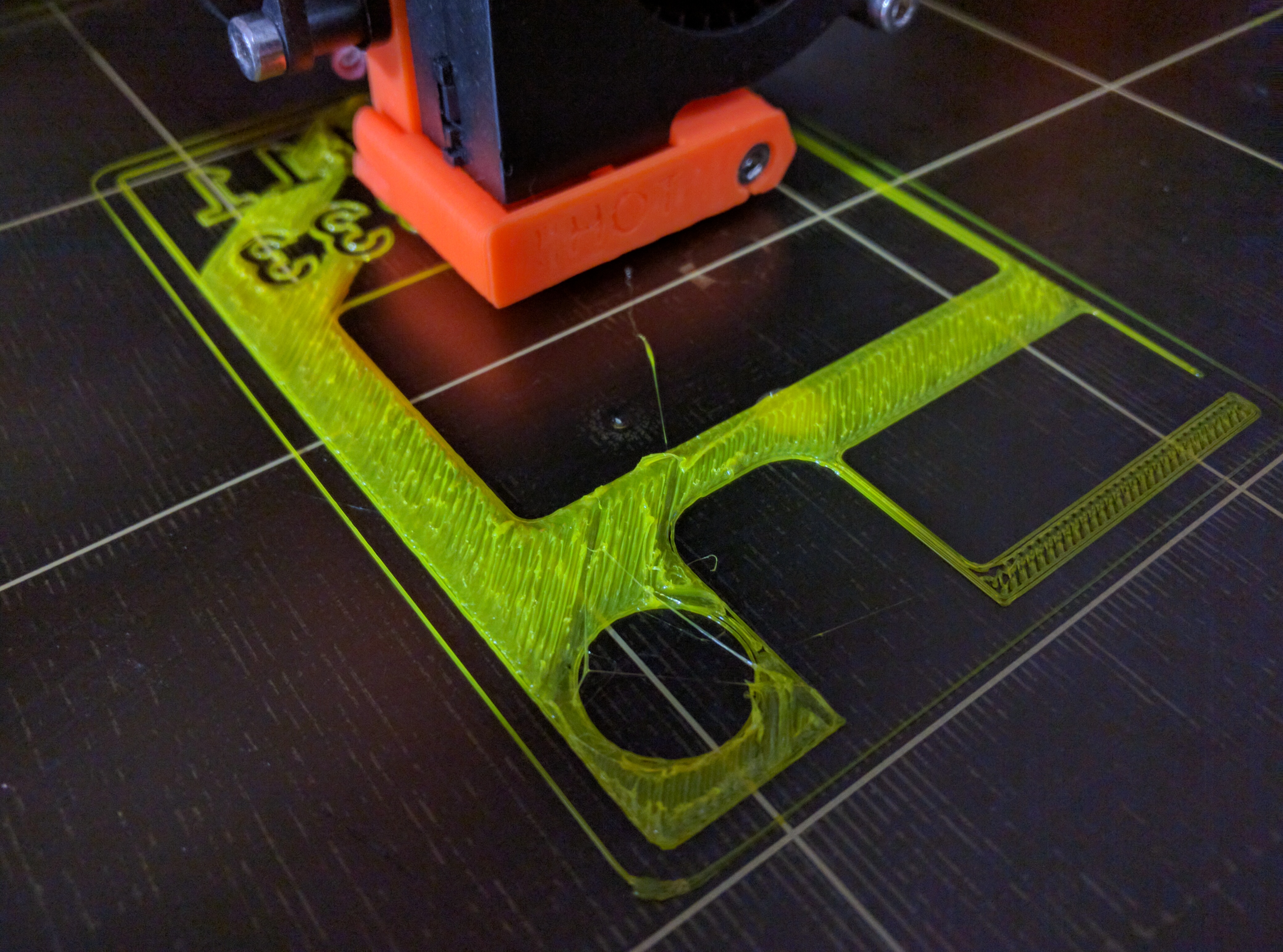

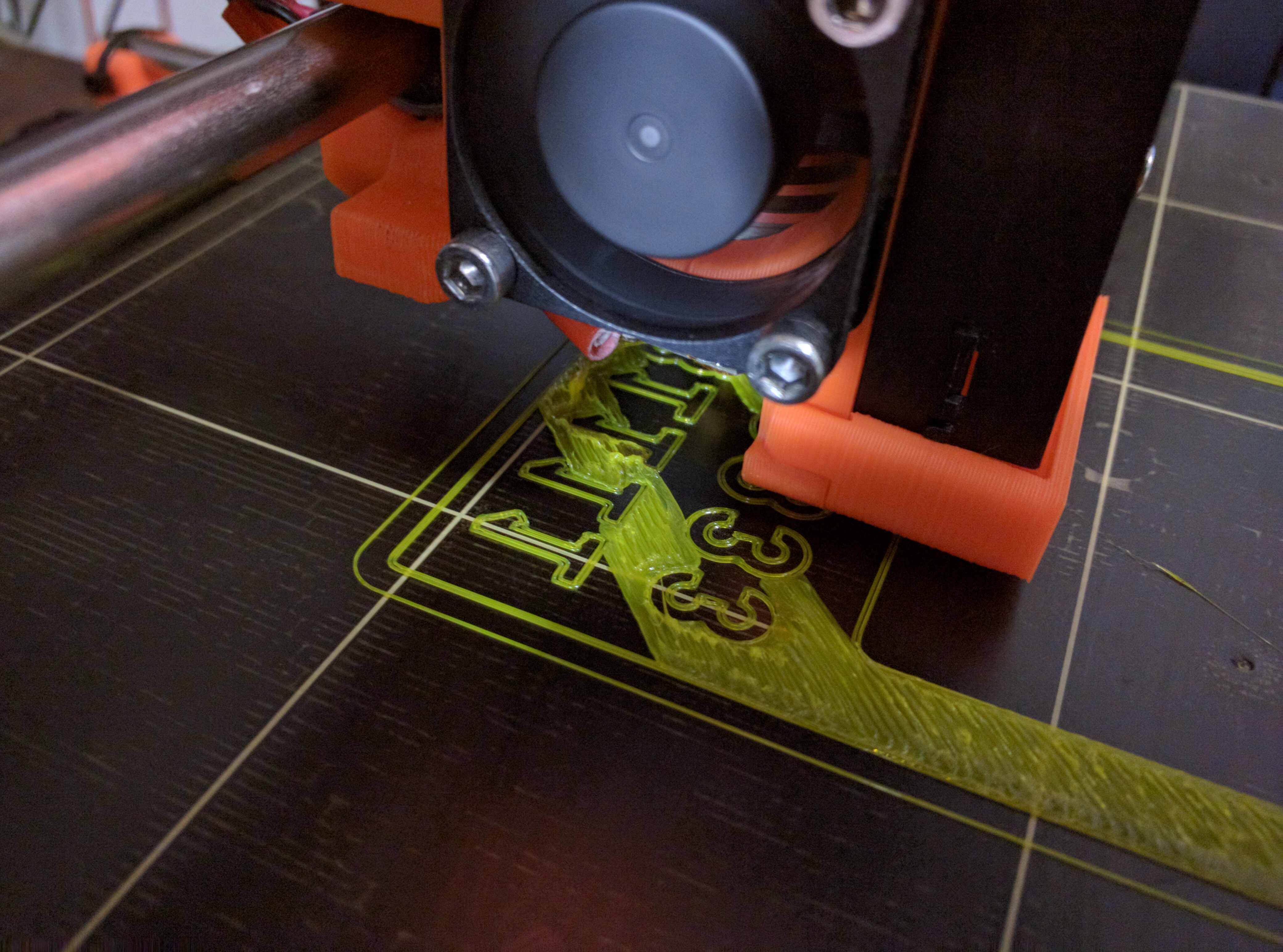

Since figuring out a couple of issues I had post MK2 upgrade I have been printing with PLA with 100% success rate. Today I set out to try some of my PETG, which I had good success with prior to the upgrade. I'm having some issues with it post upgrade. At first it looked like some strange patterns in the "flat" part of prints, the solid flat walls on the bed. Are those the "perimeters" that I see referenced? After watching the prints closely, it looked like the nozzle was being dragged through the plastic, messing it up. After doing the v2 calibration, I found that a live z adjustment of -0.420mm seemed to give the best result and that is what I had been using with my PLA prints. After doing some research on the subject I tried adjusting that value all the way up to 0.00mm with no apparent change. I then tried adjusting the first layer print speed from the default of 60% to 100% thinking that it might be extruding too fast for the speed of the nozzle, thus putting too thick a layer down. Also, no apparent change. Below are a couple of pictures of the issue I am running in to, can anyone suggest a change? Is it likely a change I'll have to make when changing from PLA to PETG? Thanks for any advice anyone can provide.

I should also mention that I am printing at the default of 240/90 and the bed adhesion is VERY good. Possibly too good, even after the bed cools down it can be a bit tough to dislodge the print.

Re: Problems printing with PETG after MK2 upgrade

I've got the exactly same issue, although I can't really increase the nozzle height anymore since that will cause the adhesion to decrease.

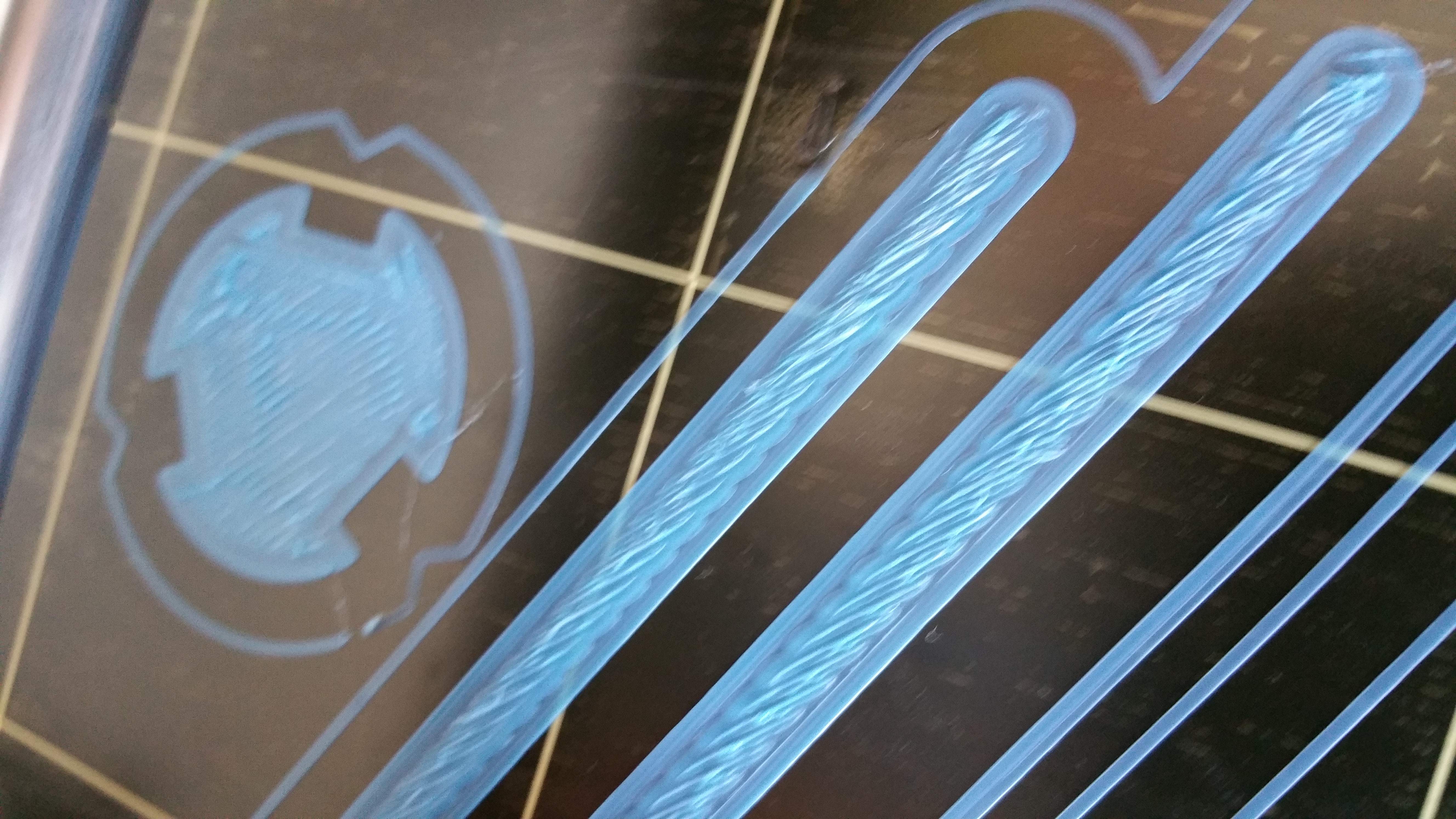

It's only my first layer though, from layer two and up it looks great.

I've tried to adjust speed, extrusion, temperature but I get those "scars" in the first layer as well...

The only thing that I haven't tried is to set the first layer height to 100%, it's 75% of the default layer height in S3D and it's 0.15 in the slic3r profile for 0.2mm layer height from prusa.

Me on MyMiniFactory!

Me on Instagram

3D Printing Live Feeds

Prusa MK2 Usergroup Slack Live Chat

Unofficial live chat by users for users.

Re: Problems printing with PETG after MK2 upgrade

I have experienced the same, but after I changed the first layer height to 0.2 mm, the first layer became perfect. I have not changed any other settings in the default Slic3r profiles from Prusa.

Re: Problems printing with PETG after MK2 upgrade

This situation is somewhat counter-intuitive and caused by a combination of the calibration GCode in combination with the firmware Z_MIN setting of 0.2mm

First, you have to understand that any first layer height set less than 0.2mm will print at 0.2mm due to the firmware Z_MIN, without the extrusion values being amended accordingly.

Secondly, the calibration GCode has been sliced with a layer height of 0.15mm - which prints at a setting of 0.2mm (firmware limit).

So, when calibrating, the calibration code is set for a line width of 0.42mm (approx) and a layer height of 0.15mm; the user will automatically attempt to get a line thicker than 0.42mm and could easily end up with a hot nozzle gap of 0.1mm* or less but the firmware believes this gap to be 0.2mm.

Now, assume that all layers are set to print at 0.15mm (bare with me on this...), the first layer will be sliced to print at 0.15mm and the second at 0.3mm. However, the first layer can only print at 0.2mm (which is actually 0.1mm, but this is OK as it has been calibrated). The second layer will print at 0.3mm which is actually 0.2mm, a difference of 0.1mm, hence over-extrusion on the second layer as well as the calibrated over-extrusion on the first layer.

All subsequent layers will be fine.

It is my belief that the only way to get all layers to print nicely is to calibrate the printer correctly and have the first layer of a print sliced to 0.2mm or greater- the subsequent layers will all be fine.

I actually have my hot nozzle gap set to 0.18mm and first layers sliced at 0.2mm, to give a slight over-extrusion on the first layer in order to ensure adhesion and to counter variation in the bed level.

All this being said, in order to produce the best prints, it is extremely important to measure the filament diameter and adjust accordingly. Also the extruder feed needs to be calibrated for each roll. Additionally, the printer will need re-calibrating** as well to take account of differing temperatures and filament.

Peter

* NOTE 1: I think the hot nozzle gap as calibrated by most users may contribute to PEI damage.

** NOTE2: When a printer is calibrated for PLA and then the user switches to ABS etc (hotter temps), if a calibration is not carried out with the new material, the hot nozzle gap will be smaller than the ~0.1mm set for PLA. We have had several forum users complaining that the PEI has lifted after printing with ABS, See note 1...

Apologies for the "lecture"...

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Problems printing with PETG after MK2 upgrade

This situation is somewhat counter-intuitive and caused by a combination of the calibration GCode in combination with the firmware Z_MIN setting of 0.2mm

First, you have to understand that any first layer height set less than 0.2mm will print at 0.2mm due to the firmware Z_MIN, without the extrusion values being amended accordingly.

Secondly, the calibration GCode has been sliced with a layer height of 0.15mm - which prints at a setting of 0.2mm (firmware limit).

So, when calibrating, the calibration code is set for a line width of 0.42mm (approx) and a layer height of 0.15mm; the user will automatically attempt to get a line thicker than 0.42mm and could easily end up with a hot nozzle gap of 0.1mm* or less but the firmware believes this gap to be 0.2mm.

Now, assume that all layers are set to print at 0.15mm (bare with me on this...), the first layer will be sliced to print at 0.15mm and the second at 0.3mm. However, the first layer can only print at 0.2mm (which is actually 0.1mm, but this is OK as it has been calibrated). The second layer will print at 0.3mm which is actually 0.2mm, a difference of 0.1mm, hence over-extrusion on the second layer as well as the calibrated over-extrusion on the first layer.

All subsequent layers will be fine.

It is my belief that the only way to get all layers to print nicely is to calibrate the printer correctly and have the first layer of a print sliced to 0.2mm or greater- the subsequent layers will all be fine.

I actually have my hot nozzle gap set to 0.18mm and first layers sliced at 0.2mm, to give a slight over-extrusion on the first layer in order to ensure adhesion and to counter variation in the bed level.

All this being said, in order to produce the best prints, it is extremely important to measure the filament diameter and adjust accordingly. Also the extruder feed needs to be calibrated for each roll. Additionally, the printer will need re-calibrating** as well to take account of differing temperatures and filament.

Peter

* NOTE 1: I think the hot nozzle gap as calibrated by most users may contribute to PEI damage.

** NOTE2: When a printer is calibrated for PLA and then the user switches to ABS etc (hotter temps), if a calibration is not carried out with the new material, the hot nozzle gap will be smaller than the ~0.1mm set for PLA. We have had several forum users complaining that the PEI has lifted after printing with ABS, See note 1...

Apologies for the "lecture"...

No thank you for the lecture! So ALWAYS slicing the first layer at 0.2 mm no matter of the layer height of the rest would be the best solution then?

Me on MyMiniFactory!

Me on Instagram

3D Printing Live Feeds

Prusa MK2 Usergroup Slack Live Chat

Unofficial live chat by users for users.

Re: Problems printing with PETG after MK2 upgrade

Patrik

No, that would not work if you have calibrated using the supplied GCode file. The first layer will always over-extrude by a height factor of 0.1mm, but the second layer would be good.

To be absolutely honest, I don't understand the logic of the 0.2mm Z_MIN and 0.15mm sliced first layer and it does tie the printer only to slicers which are capable of using Josef's supplied settings.

I (and other forum users) have been raising the Z_MIN issue (which was 0.23mm on the Mk1) ever since I started posting on here. I have also directly asked both Josef and Michal to help me understand the situation via e-mail.

Unfortunately, all such forum queries and my e-mails have been met with complete silence.

I resolved the issue with the Mk1 by amending the firmware and setting Z_MIN to 0. With the Mk2, I have adopted the strategy described previously in order to prevent potential damage to the PEI sheet, although when the firmware source is finally released, I will no doubt, make some amendments to that too.

The other option is to generate your own calibration code, but with a first layer height of 0.2mm, which would generate a hot nozzle gap of >= 0.15mm with a good "squish" and then change the slicer first layer to 0.2mm or greater.

But the best option for most users is probably to simply ignore me... 😀

Peter

P.S. you don't have to include my posts in your replies...

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Problems printing with PETG after MK2 upgrade

Thank you for your detailed explanation Peter, I will read through a couple of times to make sure I understand fully, though I think I basically get the picture.

When you say recalibrate between materials (or rolls), do you mean re-run the v2calibration code, or do the settings-> calibrate z function? Also there is the PINDA probe calibration it does each time it prints. I need to search the forum for these and make sure I understand what each are doing.

Re: Problems printing with PETG after MK2 upgrade

Michael

The 9-point probe calibration prior to the print does determine the zero (or 0.2mm) position for the nozzle gap.

However, when changing filaments, I would certainly run the V2Calibration GCode for the material to be used (but it is only available for PLA - don't know if this is a problem...) simply because the material properties would be different and a change in the Z offset may be necessary.

Actually, the answer is that I don't know as I only print with PLA on the Mk2 and I really don't know if there would be any difference.

Ahhh. Just realised that the 9-point probe calibration is only measuring the distance between the bed inserts and the end of the probe, and not nozzle gap.

I wonder how much longer the nozzle will be (closer to the bed) at higher temperatures? Probably not a lot of difference.

OK, open for discussion - anyone know any better?????

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Problems printing with PETG after MK2 upgrade

Hi Peter,

... although when the firmware source is finally released ...

I did not understand this aspect. The current source code seems already available under https://github.com/prusa3d/Prusa-Firmware/tree/MK2-BedSkewCalibration with a few recent commits. By "release" did you mean "out of beta" ?

I haven't compiled the source code , but I intend to do this soon ! Primarily this will suit my workflow better.

-- Shree

Re: Problems printing with PETG after MK2 upgrade

Hi Shree

Yes that's the one. I don't spend all my time looking at GitHub for firmware though, and there are now so many branches, the tree is getting rather large...

3 Branches with 3.01, 3.04 and now 3.05. Have to wonder why...

When the software is relatively stable (ie more than 2 weeks have passed since release), I will then download, and customise. This is not something I would attempt every few days.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Problems printing with PETG after MK2 upgrade

I followed jank's suggestion of simply changing the first layer height to 0.2mm and tried printing the part again, and got pretty much the same result. However, I also noticed that the other two parts in the print job were ok, and that it was always that same part that REALLY went bad. This is a case for a cheap LCR meter from ebay. So, I downloaded another case, one without the pinouts embossed on the top, and lo and behold it printed just fine with the 0.2mm first layer height.

Very strange, it SEEMS to be the model somehow. I also sliced it 3-4 times throughout this, and tried printing that top part that is shown in the images by itself as well. But, I'll know more as I try to print other parts.

Re: Problems printing with PETG after MK2 upgrade

Hi guys.

There is multiple things mixed together.

1) PETG first layer is too squished compared to PLA.

Each material requires different temperatures. This is causing different expansion of the nozzle and changes the distance between the probe and nozzle tip. The probe doesn’t move with thermal expansion. This might render the calibration bit different for every material. You can adjust easily during the first layer.

2) PETG sticks too well.

As we print several kilos of PETG every day (PSU covers, idler axis, RAMBo covers) we found out that cleaning with isopropyl alcohol causes too good adhesion. We adjusted the manuals accordingly. Window cleaner should be used.

The best option is I sopropyl alcohol a vailable in drugstores which is the best for ABS, PLA and others, expect for PETG where the adhesion may be too strong. Second option is to use a gentle spray of a w indow cleaner (Windex or similar) on a paper towel and wipe the surface.

http://prusa3d.com/downloads/manual/prusa3d_manual_mk2_en.pdf

3) First layer thickness and calibration.

No matter what is set to FW as Z-Min (0.2mm right now) the actual first layer height is adjusted during calibration. As long as the calibration g-code and the print settings have same layer height, it will work fine. The PETG firs layer is explained in the point 1.

I checked the math and Peter is actually right. In the transition from the first to second layer, we loose 50um which renders the second layer bit squished. But this by no means cause any troubles with layer sticking (All the pictures above are 1st layer only and explained at point1) I will check how to correct that without forcing all the customer base to recalibrate.

I chose 150um for the first layer height as it provided best first layer adhesion.

Re: Problems printing with PETG after MK2 upgrade

Hi Josef

Many thanks for the input and for joining this conversation. Apologies for the off-topic stuff.

I did do some quick calculations regarding the nozzle gap at different working temperatures and I think the maximum gap difference will only be 30 microns, which is not a huge amount when the first layer is printed at 200 microns.

But this then brings the question of first layer height. You say:

I chose 150um for the first layer height as it provided best first layer adhesion

Surely a 150 micron layer height with a nozzle gap of 200 microns would produce very poor adhesion? The best method to get users to have a first layer height of 0.2mm would be to have the calibration GCode layer height of 0.25mm - there should be no adhesion issues with that setting.

Incidentally, the default Slic3r settings for 50 micron, 0.25mm nozzle will currently print the second layer at exactly the same height as the first layer.

No matter what is set to FW as Z-Min

Yes it does matter in some slicers; as things stand, your printers do not work properly with all the slicers you support (KISS in particular).

Unfortunately, by encouraging users to have a difference between the values contained in firmware and actual values may cause issues in the future.

I have a feeling that this issue has been caused by one simple factor - that you are printing and testing in a perfect working environment. "Real World" usage of these printers is quite different. Not all of us have access to 100% IPA (Isopropyl, not the beer...), Windex and Limonene and can print in a dust-free room maintained at 30+ degrees (speculation on my part - from YouTube videos).

Josef, the bottom line is this: I do strongly believe that you (Michal et al.) are simply quite brilliant and the printers you provide are superb and represent excellent value with the potential to produce prints of a quality that is unrivalled at this price point. But there are still a few issues which need to be ironed out.

The Mk2 has been a huge leap forward and being a new product, there are still many things to learn and many improvements to make. In a few months time, all these issues will have gone away and the Mk3 will be so much better.

Many thanks again.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Problems printing with PETG after MK2 upgrade

Trying to not start too many threads here, I'm hijacking this one.

Testing some PETG (from maker geek) today, and the print looks great when it comes out, but the layer bonding is terrible, I can tear it apart one by one.

Layer Height: 0.2

Bed: 80 degrees

Nozzle: 250 degrees

Under extrusion?

Fan is off for the first layer, and turns on at the second layer.

Me on MyMiniFactory!

Me on Instagram

3D Printing Live Feeds

Prusa MK2 Usergroup Slack Live Chat

Unofficial live chat by users for users.

Re: Problems printing with PETG after MK2 upgrade

Patrik

There are some very useful hints here: http://forum.makergear.com/viewtopic.php?f=11&t=2593

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Problems printing with PETG after MK2 upgrade

Patrik

There are some very useful hints here: http://forum.makergear.com/viewtopic.php?f=11&t=2593

Peter

hehe just read that, before opening up this forum today!

I'm re-printing, without fan, and some other adjustments. We'll see if it makes a difference.

Me on MyMiniFactory!

Me on Instagram

3D Printing Live Feeds

Prusa MK2 Usergroup Slack Live Chat

Unofficial live chat by users for users.

Re: Problems printing with PETG after MK2 upgrade

Patrik

I think print speed may be a clue. When in doubt, print a test piece really slow and then gradually increase the speeds.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Problems printing with PETG after MK2 upgrade

Patrik

I think print speed may be a clue. When in doubt, print a test piece really slow and then gradually increase the speeds.

Peter

Im always printing at 30mm/s 😀 (with first layer 30% of that) hehe

Me on MyMiniFactory!

Me on Instagram

3D Printing Live Feeds

Prusa MK2 Usergroup Slack Live Chat

Unofficial live chat by users for users.