Problem with tall, thin columns printed in ABS

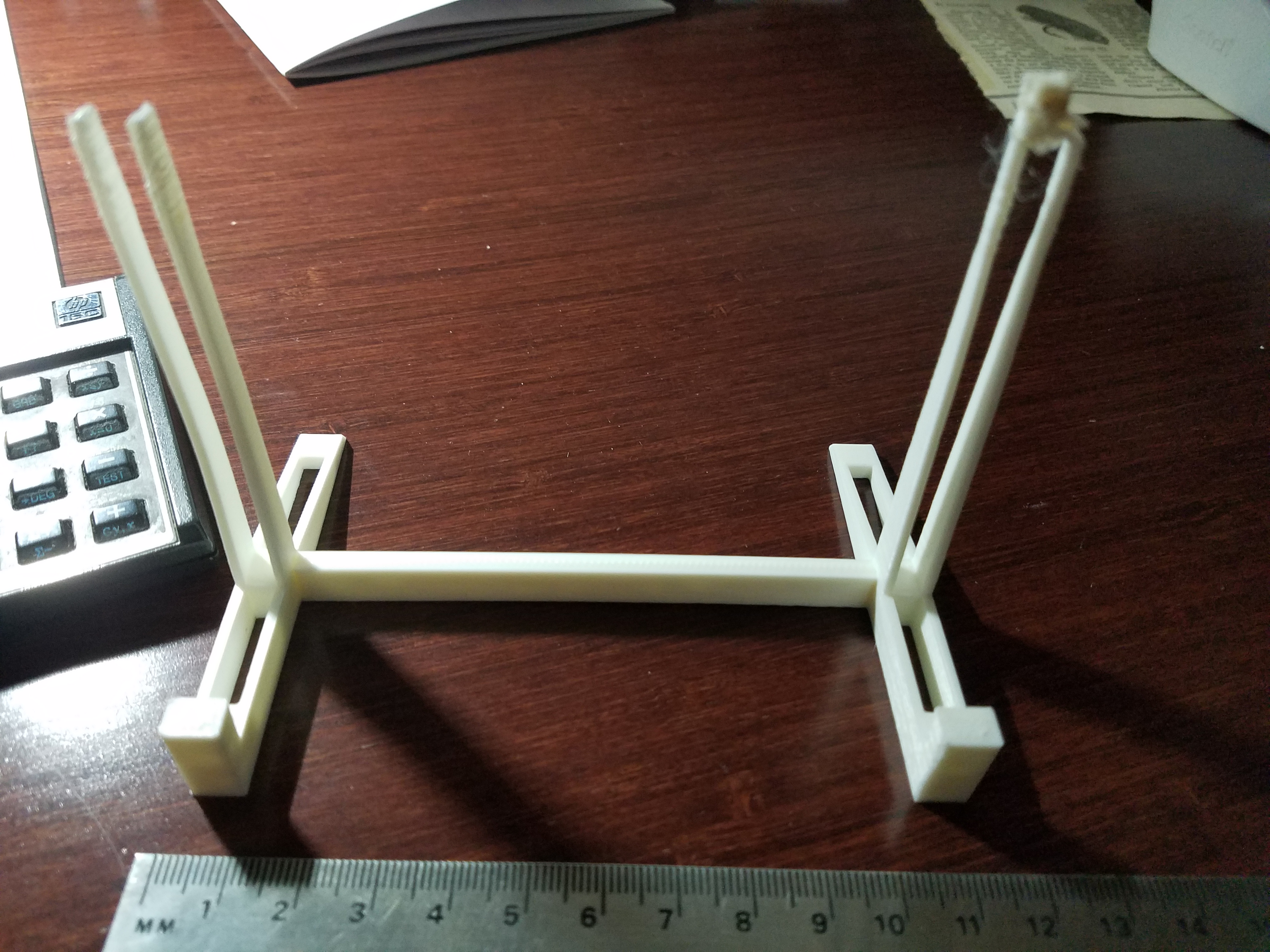

It took me a while to get things sorted when printing with ABS. I had only minor problems with PLA or TPU but I about gave up on ABS. After lots of playing around with the live Z-adjustment, temperatures, and bed adhesion, I seem to have it mostly solved. My latest ABS problem was when I printed an object (a tablet holder) that had tall, narrow columns, as shown below:

The tablet holder - and a taller one just like it - printed fine with PLA. When printed in ABS, the columns were no longer printing properly and the tops just ended up being a couple of blobs after about 2" (5 cm) above the build plate.

I print in an enclosure and I keep the enclosure around 100F (38C) as measured above the printer (not just near the build plate) when printing ABS. I'm wondering if the problem I'm seeing is more likely a temperature problem or a flex problem? If it's flex, I can pretty easily solve that by making the columns solid. If it's a temperature issue, I'm wondering if I need to add a heat lamp to my enclosure. Any suggestions or ideas? I don't really need to print this in ABS, but I'm trying to push the limits with ABS so I know what to expect.

Re: Problem with tall, thin columns printed in ABS

Having limited ABS experience my guess would be the parts were flexing once they got that tall.

If those are 2" tall they must be pretty thin.

I would probably try again after making the columns solid like you suggested.

Or at least tying the 2 separate columns into an I-beam type structure to strengthen them up a bit.

Re: Problem with tall, thin columns printed in ABS

reducing the print speed above 25mm of height wouldn't hurt as well...

btw.: with this structure, i guess you would have had the same problem with pla as well.

dem inscheniör is' nix zu schwör...

Re: Problem with tall, thin columns printed in ABS

Yes, it was a flex problem, not a heat problem. I made the columns solid and it printed just fine in ABS. Sorry I forgot to grab a photo before putting on the cushions. This print was just to experiment with ABS. The original design in PLA is cheaper and works fine with the thin columns. Plus, I like the look of the thin columns.

By making the columns solid my estimated cost went from about $0.30 to $0.50. That's one reason I like to make my designs as minimalist as possible. When I look at some of the designs on Thingiverse for various items, I'm surprised at the amount of filament needed for the print. There are some great looking designs but I can't see using half a spool of filament to print, say, a paper-towel holder.

Thanks for the assist.