Print Dry

We just received a filament dryer that works in line called a PrintDry. I would like to know if anyone has any experience with this unit and any recommendations. We normally dry all of filament prior to use. 140f for 24hrs. Now we are going to dry it in the oven same as before and put it in the this inline dryer. An extra step. First use will be this afternoon.

Re: Print Dry

Ive honestly never found a need to dry any of my filaments (besides Nylon) Though i just generally use PLA, ABS, or PET, ive never had a problem with excess moisture.

Looks like an intresting product. I generallly just keep all my filaments in a couple large bins with a couple homemade dessicant boxes in each.

Re: Print Dry

+1 re Erron's post.

I have had filament in the open for more than 6 months and it just works.

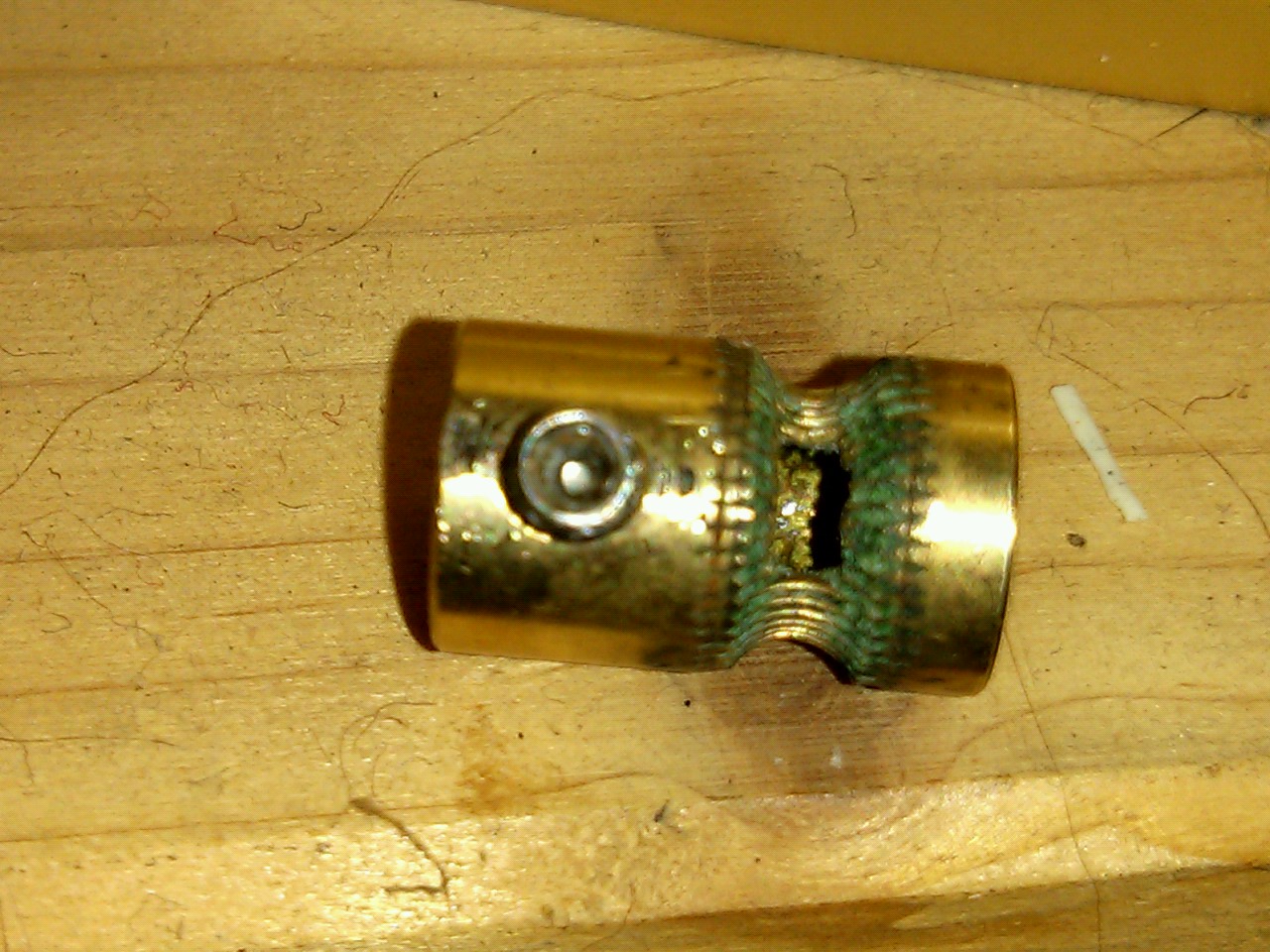

The only problem I have had caused partly by moisture in the filament is with the brass filament drive gear:

The corrosion on the gear was most likely caused by steam being forced back up the PTFE tubing and corroding the brass.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Print Dry

Seems like a way over-priced food dehydrator. They want $79 and I can get a food dehydrator for $30.

Re: Print Dry

After a few days with it on one machine we have found:

1 That it will free up our drying ovens for other task. Replaced a 1500 to 2000 dollar lab oven with a 100 unit, great.

2. PLA that is heated to 60C will comes out very flexible and tends to put bends in it. This causes feed problems. Solution lower the temp to 50c. Just make sure you have your next roll on top so it will be drying.

3. The parts we are building have to be machined after they are printed. The tensile is higher on dried pla, and it machines better.

For what is worth, If we where just making things for everyday use then a dryer is over kill for PLA. In addition our PLA has some adders that make it absorb water quicker to revert it back to some form of starch.