PET filament and print bed film blistering

I printed some test models with PET last night using default Prusa PET settings in Slic3r.

140/90 temps. When I removed the prints the film on the bed appeared blistered in several places where the print was located. I cannot confirm if it's just the film or if the bed itself has become delaminated in some manner. I expect it's just the film. Either way I can feel a bump when running my finger across the area.

Any ideas on why the blisters on the print bed occurred? Anyone else experience this yet? Corrective action before printing more articles?

Thanks.

Re: PET filament and print bed film blistering

You do mean 240/90 right?

Me on MyMiniFactory!

Me on Instagram

3D Printing Live Feeds

Prusa MK2 Usergroup Slack Live Chat

Unofficial live chat by users for users.

Re: PET filament and print bed film blistering

PET is sticking very well, so to unstick it I wait for the bed to be cold, I use with lots of cautious a flat sharp knife to level a bit one corner, then I insert the spatula just below it and push it under the object. Never try to force it by pulling the part.

If something came off it's probably the PEI sheet. Do you have a picture ?

As Patrick I presume you were printing at 240/90.

I'm like Jon Snow, I know nothing.

Re: PET filament and print bed film blistering

I actually have 2 spots on my PEI sheet that peeled up after a PETG print. I'm pretty sure at the time I had the z-axis too low and that caused the problem.

PETG doesn't need the squish on the first layer that PLA or ABS need to stick to the bed. On a glass or aluminum bed this isn't as much of a problem but with a PEI sheet it will pull the sheet off the bed.

Re: PET filament and print bed film blistering

PEI has a glass transition temperature of 217 degrees, so printing hotter temperatures than that and having the nozzle too close could easily cause the PEI to transition and deform.

I guess the only way to remove the deformation would be with a localised heat gun and some pressure on the surface.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: PET filament and print bed film blistering

Yes, I mean 240/90.

I pried the print off by twisting it sideways, not upwards.

I'll try lowering the temps a bit and see if that helps. It seemed to ooze a bit much anyway. I'll also try raising the z axis a tad. Other than that I assume the PEI film is ruined in those blister spots. Not sure what a heat gun would do for yhe PEI, but I'll investigate.

Re: PET filament and print bed film blistering

Seems i've also managed to do this to the PEI bed when printing PETG...my auto-leveling seems to be disable when printing from USB so i had to live adjust z at the start of the print and after removing the object, my bed looks (and feels) blistered. I didn't think the nozzle was too low as i was still having issues getting some of the print to stick and also had warpage in the bottom right corner. Also waited until the bed was totally cool until removing the print and didn't need tons of force to remove it...

Re: PET filament and print bed film blistering

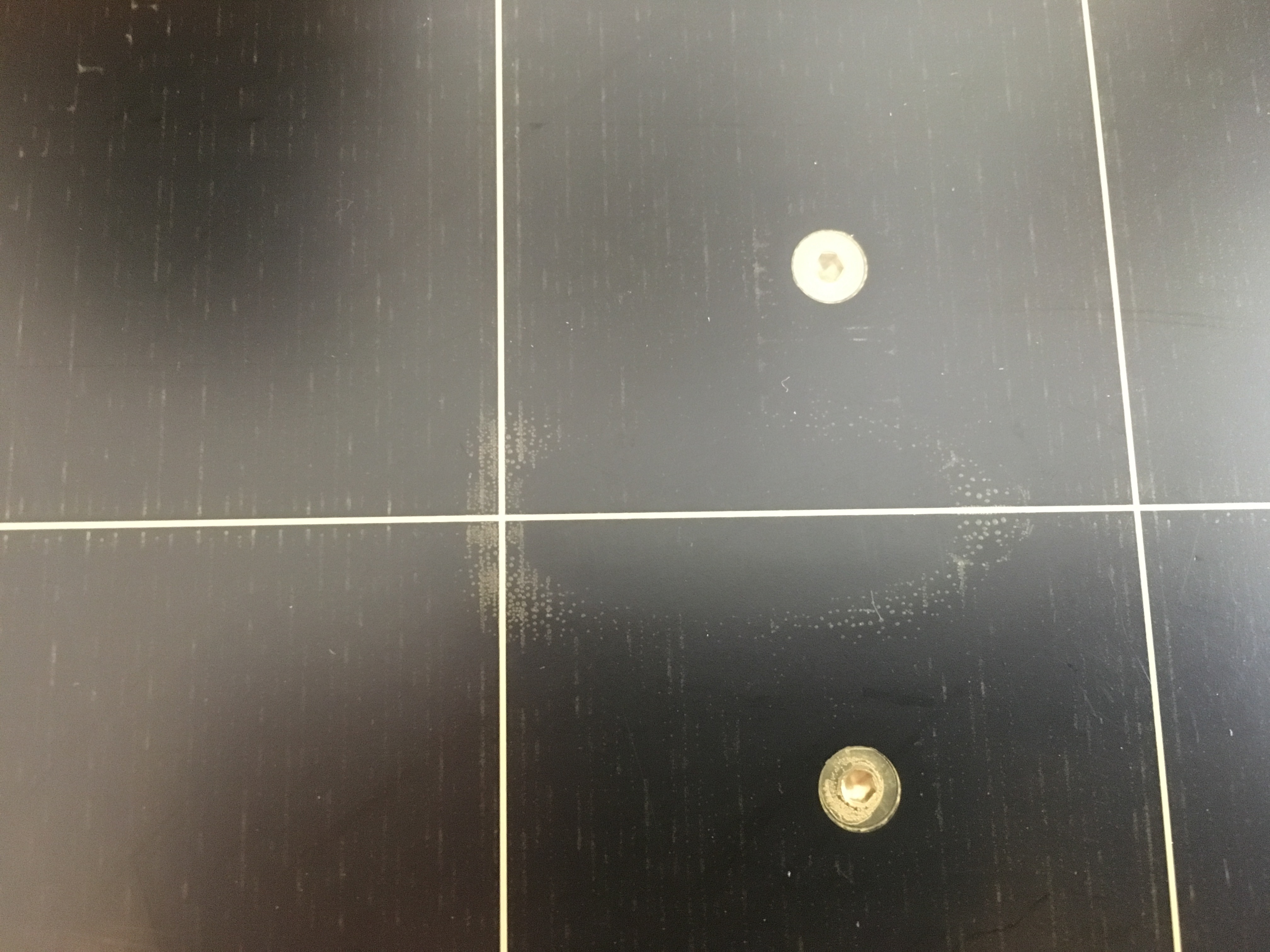

oh boy, it seems to be getting worse. Very curious as to what is causing this issue as i don't think it's the z-axis height since only the perimeters of the objects appears on the PEI bed. You can see the current state of the bed after 4 prints below (with a couple parts located below it).

I've been using a flexible metal spatula/knife to slide under the corner of the prints once they've cooled and they actually seem to pop off relatively easily. If i raise the z-height any further then the filament won't stick when dragging a finger slightly across it (during V2calibration) so i figure it's at a good height...Kinda scared to keep printing 😥

Re: PET filament and print bed film blistering

I am observing an identical problem. For me, it's after I printed a couple of 3DBenchy prints to test print quality.

It's incredibly concerning, and I would like to know if the problem is with the film being too thin or the adhesive not being temperature-resistant enough, or both.

The ease of use of the PEI print surface is great, but not if one has to constantly worry about the surface bubbling.

My surface also now has bubbling in the shape of the 3DBenchy's base, and it is also easy to feel with just the finger.

Re: PET filament and print bed film blistering

Hi all,

I have been printing exclusively with PETG at 240/90 since the MK2 Upgrade.

After my 3rd print, I ripped a small hole in the PEI trying to pry a print off.

After that experience, for me, the best option I have found is to let the bed cool to around 60C and then use dental floss slid under one corner of the print, (try not to get in between a layer) and work the dental floss under the print to the other side.

I wrap the dental floss around a wooden dowel at each end of the floss to stop it cutting into my fingers.

Normally it will pop right off.

Small prints just break away easily but prints that have a large surface area (boxes etc) can be very stubborn. For me, letting the bed go totally cool (around 15C) seem to exacerbate the problem.

I'm finding the new PEI film a joy compared to glass and glue stick.

To avoid excessive wear, i also move my prints around the bed in slicer so that the whole bed gets used. With the auto leveling, I can sit the print anywhere and it will print perfectly.

I also do a very squishy first layer. So much so that the finish is smooth and you can't see the lines in the first layer (when removed form the bed) as it has all squished together.

The dental floss trick is worth a try for those with stubborn prints.

Cheers

Re: PET filament and print bed film blistering

I'm also having trouble with PETG sticking far too well and leaving marks on the PEI bed. With the MK1, when prints stuck too well to the glass, I removed the glass bed and put it in the freezer. (Purple Elmer's glue sticks did an amazing job of sticking.) 10 minutes later, everything popped off with no trouble. Sometimes I even heard objects pop off inside the freezer. With the MK2, that's sadly no longer an option. Don't get me wrong, the auto-leveling of the MK2 is excellent and makes up for the loss, but I'd like to find a solution.

Maybe it would be best to print the first layer of PETG at a lower temperature. I've found that most of the print should be done at 250 C for strong adhesion between layers, but maybe the first layer should be around 220 or 230. I'll try it.

Re: PET filament and print bed film blistering

If I end up replacing the PEI surface, would the Lulzbot method work?

https://ohai.lulzbot.com/project/mini-replacing-pei/maintenance-repairs/

Also, does anyone know how thick the replacement sheet should be?

Re: PET filament and print bed film blistering

I’ve been printing with PETG for a couple of weeks with no blistering at all. After my printer arrived I printed for about a week with PLA, getting used to the printer and adjusting the Z height for good — but not extreme — bed adhesion. When I began printing with PETG I backed the Z setting down about 20 microns and found that the model still stuck to the bed, so that's where I’ve left it.

I’m using Simplify3D with Josef Prusa’s PETG settings: extruder 240°, bed 90°.

I’ve had no warping. Everything — even big prints — stays anchored to the bed. But after the bed cools the prints pop off with just a bit of encouragement from a putty knife.

The bed is unscarred. No blisters, no gouges, no scratches.

Re: PET filament and print bed film blistering

Lucky you. 🙂 I also started with Josef's default PETG settings in Cura, but I found that parts printed at 240C are much weaker than parts printed at 250C. Even so, I did all of the following and the parts still had excessive adhesion to the bed and left a mark:

- Printed at 240C / 55C

- Adjusted Z to about 100 microns too high (leaving gaps between every line)

- Waited until the bed was cool (19C)

- Used an electronics duster to chill the bed

- Put ice in bags on the bed to cool it more (didn't really work, only got down to 18C, and attracted condensation leading to water on the bed, oops)

For now I'm using PLA only until I can find a solution. PLA always pops off. Printing the first layer of PETG at a low temperature could be promising, although it won't extrude if I go too low.

Re: PET filament and print bed film blistering

It would seem that this is also a serious problem that more than a small handful of people are having.

Would the problem be alleviated if we used a thicker PEI sheet? A different adhesive?

Re: PET filament and print bed film blistering

What about applying a diluted PVA coating to the top of the bed? Maybe try 1:8 (PVA:water) This will ensure a good adhesion, but the PVA will be able to be dissolved in water to remove the object, but may provide a thermal barrier that is enough to prevent the PEI from passing it's glass transition point?

I am surmising that the problem is stemming from the fact that the PEI has a glass transition point of 217°C and normally this would not be a problem, but when the plastic used is heated to higher than this, it is exceeding this point, the PEI becomes soft and malleable and is blistering on contact. So what is needed is something to provide a heat barrier between the hot plastic being extruded and the PEI, hence my suggestion of the PVA... This should allow the bed temp to be lowered as well which will help reduce the temps.

Re: PET filament and print bed film blistering

Has anyone tried printing PET onto blue tape? That seems to be an old favourite that has gone out of fashion...

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: PET filament and print bed film blistering

The PVA and blue tape suggestions sound interesting. Maybe we could bring back Kapton too. 😉

There's good news from my house: the marks on the PEI surface seem to be fading. With each print they seem to become less visible. Is it possible that sustaining 55C over several hours with lots of movement causes PEI to settle? That would be amazing if it's true.

Re: PET filament and print bed film blistering

Printing near the glass transition temperature is why PEI is interesting, as I suspect that's what gives it the "stick" when it's heated up. The newly extruded filament will transfer some of its heat into the PEI and briefly, locally change its properties to stick to the print.

But this means care needs to be taken when printing with this surface since you are literally changing it when you print on it.

My opinion is don't overdo it with the heat and the first layer offset. I heat the bed as little as possible. In fact, with TPU, I leave the bed unpowered and slightly chill it before printing so it actually counteracts some of thermal effects.

I haven't used PETG yet on this printer, but I have printed it successfully on an another unheated bed with just glue stick and kapton. Since the trick with PETG is mostly to get it to stick and not mechanical shrinkage issues, I find it hard to believe that 90C bed temp is really necessary.

I also set a very conservative first layer -- I don't overextrude the first layer and make sure that lines are visible to control contact area (and reduce first-layer deformation). To compensate for loss of contact area, I just drop the first layer speeds to ~70-80%, or at worst add "corner adhesion discs" to my model. (I'd rather snip off small adhesion discs in a few key areas than have to clean up an entire deformed 1st layer.) I might have the crappiest *looking* first layer, but as long as it sticks, is dimensionally accurate, and doesn't destroy my printer, that's all I care about.

All of this combined gives me the perfect amount of stick.

There is also a layer of adhesive between the PEI and print bed which might also be affected by all of this. And certainly any trapped air bubbles in that layer as well. Your print should stick well enough to print, but stick less than the adhesive under the surface. That's the game here.

My PEI sheet, from factory, had a similar blister on it from the sample logo print because, again, whoever assembled and tested my printer overdid it. It's not cool to damage my printer to prove that it was working if you ask me.

PEI is an interesting build surface to print with, but I wish they would turn down the marketing hyperbole a few notches because it's not trouble free, and it's not that durable.

Prusa's PEI replacement instructions are here:

http://manual.prusa3d.com/Guide/Replacing+the+PEI+sheet/133

Bottom line: be gentle, precise, and deliberate.