Order delay gave me time to build a well-functioning enclosure

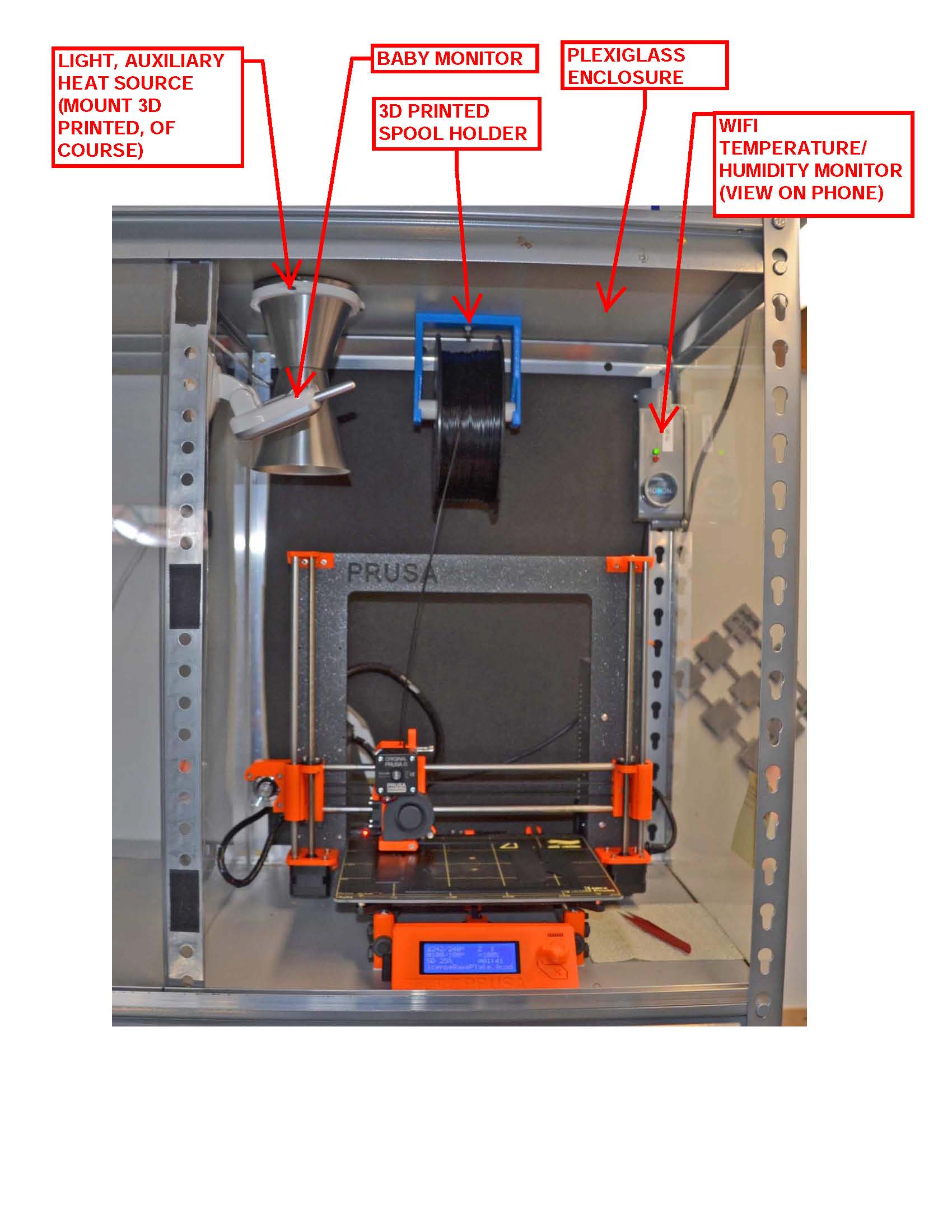

The 2-month delay in receiving my MK2 turned out to be a blessing. I had time to learn some of the necessary tools (123D Design, Slic3r) and time to build an enclosure. I had to make a few modifications to the enclosure after receiving the printer but at this point I have it pretty well nailed down.

The printer is in an unheated garage so an enclosure is important. While I've never seen the garage get below 60F (16C), I usually heat the enclosure up to a minimum of 75F (24C) before printing. I mounted an old table lamp to the top of the enclosure to help heat the enclosure. Luckily I had the ability to print a 3D mount for the lamp! I placed foam insulation at the back of the enclosure for insulation and to give the back some distance/flex so the printer cables don't hang up. The front has a simple sliding plexiglass door.

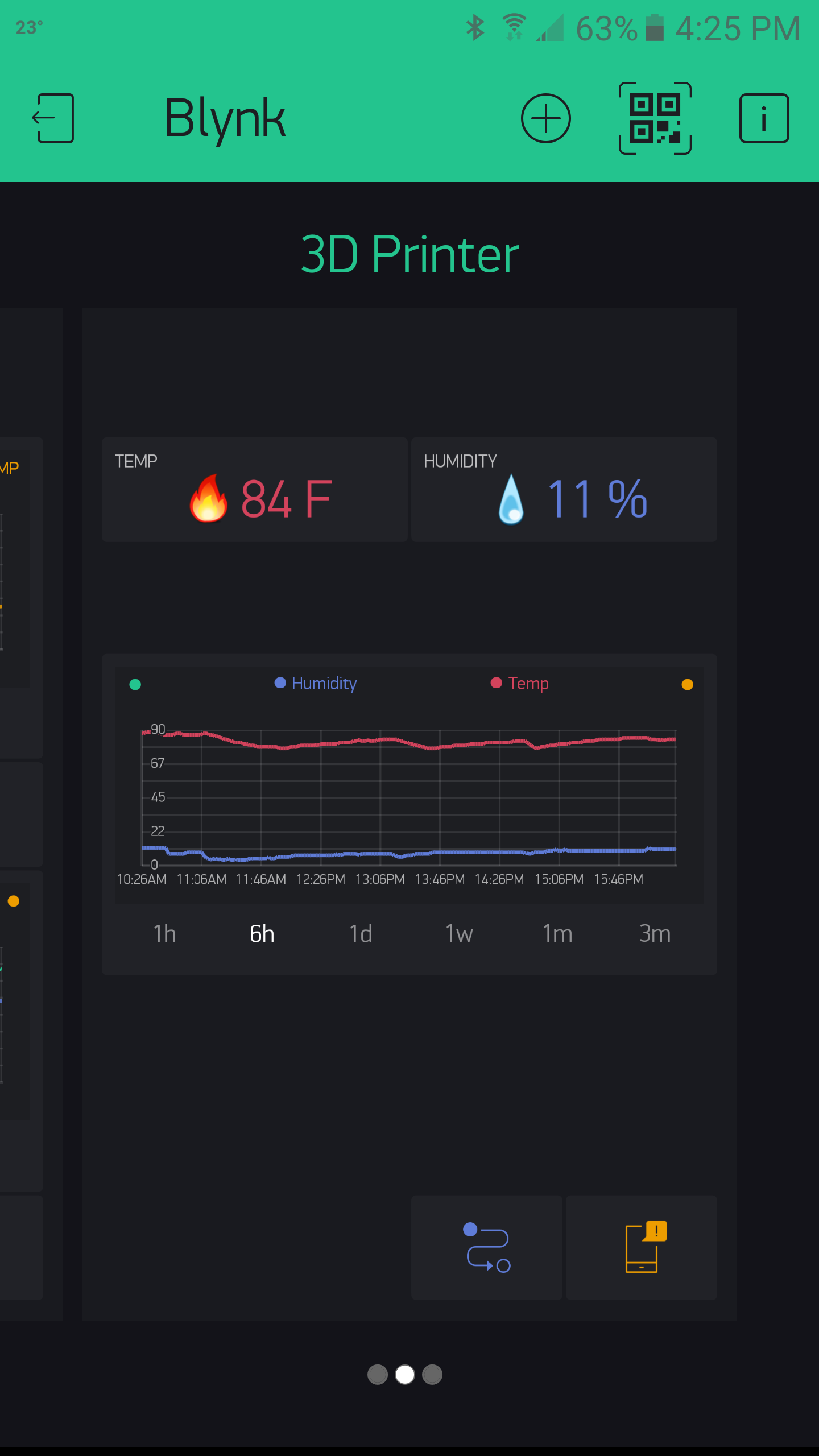

Next up was a way to monitor the temperature inside the enclosure. Placing a thermometer inside the enclosure would be way too simple so I opted to use a Particle Photon which sends the temperature and humidity to my phone or tablet via Blynk. I added a couple LED lights inside the enclosure so I could see visually if I was within my target temperature range. Plus, LED lights always look cool.

As an added bonus, I can set a notification within Blynk to trigger a notification if the temperature falls too low or goes too high.

I replaced the stock filament spool holder with a new one, 3D printed of course. The spools spin on a piece of PVC and it's very easy to switch out spools; the spool just slides out toward the front. I made the holder wide enough to handle different size spools although I might reprint it a tad taller as it's a little tight with one of the spools I received from eSun. I actually think an inverted version of this, mounted to the printer frame, would be a big improvement to the stock spool holder and would add very little cost to the build.

Finally, I added a baby monitor to keep an eye on the progress, especially when color printing. This has worked out really well as I can just set the volume on the monitor so I can hear the "beep" when it's time to change colors. Plus, you can tell when the print finishes which is nice when printing with ABS so I can remove the print before the bed cools.

I am incredibly happy with the MK2. I've been printing pretty much non-stop since I received it and have had essentially no problems after I learned how to properly set the Z and how to prepare the bed for different materials. What a great machine!

Re: Order delay gave me time to build a well-functioning enclosure

Nice! I just may have to use some of those ideas in my enclosure as well.

Have you made any tweaks to it at all or is it still working great?

Re: Order delay gave me time to build a well-functioning enclosure

Nice 🙂 I was looking for a way to integrate sensors and be able to monitor things remotely. That blynk app is really cool.

I'm also planning on building my enclosure with those metal profiles. They're cheap, sturdy and the corners, connectors and accessories are always available on DIY and construction stores.

Re: Order delay gave me time to build a well-functioning enclosure

No tweaks yet. I'm happy with the way it's working. The handiest part is the baby monitor. It's a real time saver as I can go about my day without worrying about constantly stepping into the garage to see how things are progressing.

I do think about going a little further with the sensors. My thought is to monitor the temperatures both inside and outside the enclosure and then use the temperature difference to 1) notify me when printing is complete, and 2) trigger a relay to shut everything down after the print is complete. With the Blynk app I could also trigger a relay to warm up the enclosure so it's ready for printing on a cold day. It's pretty easy to get carried away with this stuff so, for now, I'm focusing on printing. It seems like I run the printer most of the day, every day. It's a great machine.