My method of clearing the filament stuck in heat break

I have had PLA jamming in the heat break for various reasons. I am using a simple method to clear the heat break. I am sharing the method with you all. I'd love to get some thoughts on the safety of this method, possible drawbacks, pitfalls, etc.

My objective is to clear the heat break with the least possible disassembly. I did not want to remove the heat sink, nozzle, hotend, etc.

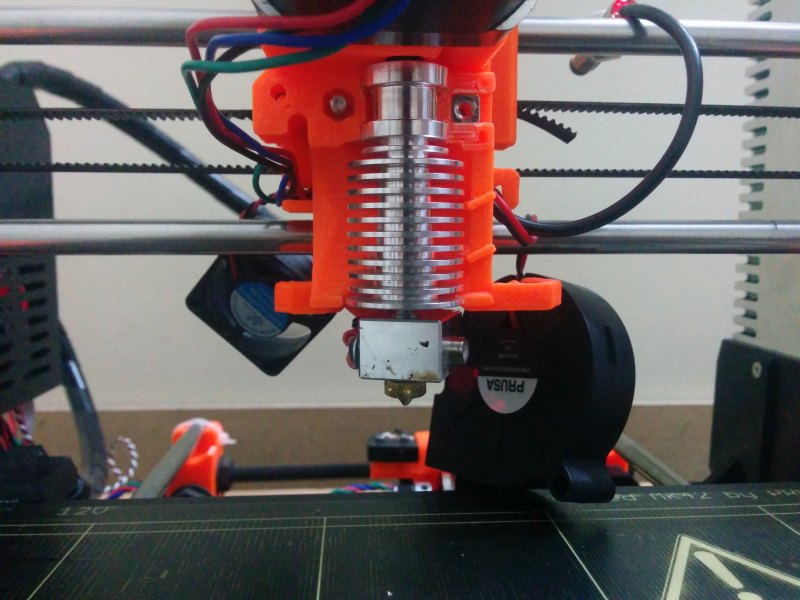

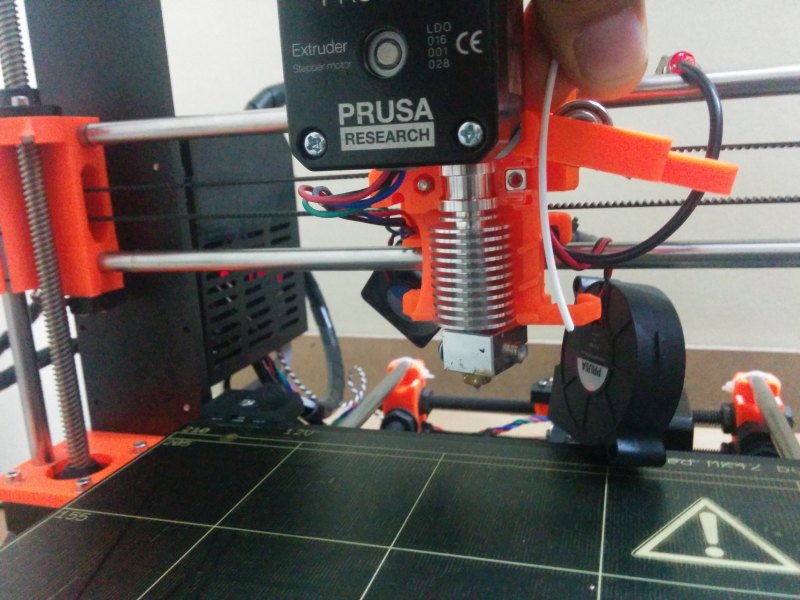

As a first step, I unscrew the heat sink fan and move it away. I also move away the cooling fan and the PINDA probe. Next, the extruder cover is removed. This completely exposes the heat sink portion. I move things away to make sure that all the sensitive items are as far away from the heat as possible. At this point, things look like this :

Remove the extruder idler screws. At this point I push a length of filament as far as possible through the PTFE tube, take it out, and reconfirm that the block is in the heat break.

By careful measurement, it should be possible to figure out exactly how much filament is stuck inside. Note that the E3D design is freely available - engineering drawings with dimensions are at http://wiki.e3d-online.com/wiki/E3D-v6_Documentation . I haven't done this exercise, however.

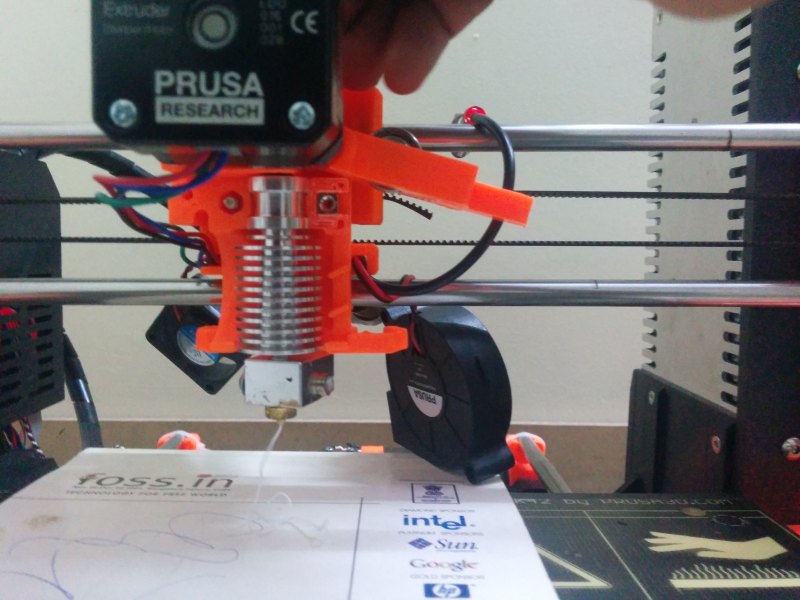

Next, heat the nozzle to 210 degrees. Place a little book or piece of cardboard over the heat bed. If anything hot falls down, this will ensure that the heat bed is not impacted.

Wait a couple of minutes. Regularly keep sensing the temperature of the heat sink. Exercise care to ensure I don't burn up any fingers. Once think the heat sink is hot enough, try pushing the filament in, through the PTFE tube. Note that the whole heatsink does not need to be hot - only the bottom portion closer to the heat break. That's where the filament is stuck.

In a few minutes (2-4 minutes maximum - I did not time it), I am able to push the filament down with minimal effort and do some manual extrusion.

I now pull out the filament in quick motion. I issue a "Preheat | Cool down" command. The heat sink is in contact with ABS all the while, so ensure that you don't keep it hot for any longer than absolutely required. You certainly don't want the ABS to melt !

After everything cools down, push a filament through the PTFE tube as far as possible, check that the length that you are able to push in is much more than earlier - and something that looks enough to reach the heater block.

If you reached here, congratulations! Your heat break is clear. Put back everything back as it was earlier. Move the Z axis as far up as possible. Issue a Z calibration & check everything is still in order.

When I first thought of this process, I was a bit worried that I might melt some ABS parts. I was even more scared of opening the E3D v6 assembly. That's why I tried it. The used this method a second time yesterday, and I could do everything very smoothly.

What do you guys think of this ? Note that I mostly use only PLA. Will this work with other materials ?

Re: My method of clearing the filament stuck in heat break

I've been successful with just halting the heatsink fan on the side for a while, keeping constant downward pressure with the filament rather than taking anything apart. It doesn't always work, but for me it's a good first step. If everything goes well the heatbreak gets to 50+ degrees and softens the plastic that's jamming it.

Re: My method of clearing the filament stuck in heat break

Remove the extruder idler screws. At this point I push a length of filament as far as possible through the PTFE tube, take it out, and reconfirm that the block is in the heat break.

By careful measurement, it should be possible to figure out exactly how much filament is stuck inside. Note that the E3D design is freely available - engineering drawings with dimensions are at http://wiki.e3d-online.com/wiki/E3D-v6_Documentation . I haven't done this exercise, however.

Next, heat the nozzle to 210 degrees. Place a little book or piece of cardboard over the heat bed. If anything hot falls down, this will ensure that the heat bed is not impacted.

Wait a couple of minutes. Regularly keep sensing the temperature of the heat sink. Exercise care to ensure I don't burn up any fingers. Once think the heat sink is hot enough, try pushing the filament in, through the PTFE tube. Note that the whole heatsink does not need to be hot - only the bottom portion closer to the heat break. That's where the filament is stuck.

In a few minutes (2-4 minutes maximum - I did not time it), I am able to push the filament down with minimal effort and do some manual extrusion.

I now pull out the filament in quick motion. I issue a "Preheat | Cool down" command. The heat sink is in contact with ABS all the while, so ensure that you don't keep it hot for any longer than absolutely required. You certainly don't want the ABS to melt !

After everything cools down, push a filament through the PTFE tube as far as possible, check that the length that you are able to push in is much more than earlier - and something that looks enough to reach the heater block.

If you reached here, congratulations! Your heat break is clear. Put back everything back as it was earlier. Move the Z axis as far up as possible. Issue a Z calibration & check everything is still in order.

When I first thought of this process, I was a bit worried that I might melt some ABS parts. I was even more scared of opening the E3D v6 assembly. That's why I tried it. The used this method a second time yesterday, and I could do everything very smoothly.

What do you guys think of this ? Note that I mostly use only PLA. Will this work with other materials ?

Just to check, you're pushing only ABS into the extruder to clear it out, but never actually extruding the ABS, right? This might be very useful for me as my extruder assembly is currently disassembled after a jam in the heat break.

Re: My method of clearing the filament stuck in heat break

Just to check, you're pushing only ABS into the extruder to clear it out, but never actually extruding the ABS, right? This might be very useful for me as my extruder assembly is currently disassembled after a jam in the heat break.

I am pushing only PLA filament, David. ABS may require higher temperatures, so I am not sure how safe that would be. I would advise you to be extremely careful & watchful if you are trying this.

The ABS reference above is for the 3D printed printer (orange) components. I did not want them to melt due to the heat.

I've been successful with just halting the heatsink fan on the side for a while, keeping constant downward pressure with the filament rather than taking anything apart. It doesn't always work, but for me it's a good first step. If everything goes well the heatbreak gets to 50+ degrees and softens the plastic that's jamming it.

I used this yesterday ! Works well too. I disconnected the heatsink fan, quickly cleared off everything. And put back the fan 😀

Re: My method of clearing the filament stuck in heat break

What is causing the blockage. Keep my finger crossed I have never had one, YET.

Re: My method of clearing the filament stuck in heat break

I had the same issue on another printer with an E3DV6 hotend with a jam in the nozzle and heatbreak. I took my hotend apart and heated up the nozzle on my gas hob to clear it, with a drill bit approx same size as filament. Also a fine tool I have bought to clear the 0.4 mm nozzle hole. I also heated up the heatbreak in the gas flame and used the same drill bit. Blockage cleared in seconds. The thing is not to over cook things.

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: My method of clearing the filament stuck in heat break

What is causing the blockage. Keep my finger crossed I have never had one, YET.

Hopefully you won't encounter this. This is linked most often to retraction settings. The E3D does not like large retractions. The recommended (and default) value seems to be 0.8 mm. I have had jamming when I used the incorrect printer preset ("default") as well as when I increased the retraction manually - I got jamming at even 1.5 mm.

Re: My method of clearing the filament stuck in heat break

In simplify3d would this be the setting under extruder /Ooze control/retraction/retraction distance If so mine is set at 1.9mm Not sure if that is a carry over from settings on the Erectorbot or from PRUSA recommendation.

Still never had the problem

Re: My method of clearing the filament stuck in heat break

The people from E3D suggest a retraction setting for PLA no higher than 0.8 mm. For ABS they say 0.5mm is good. They encourage not to set the retraction too high, as they are a commom cause for jamming.

Re: My method of clearing the filament stuck in heat break

My method for what it's worth. Follow the directions for a clogged nozzle. Once front fan is removed, shroud is off and nozzle is removed move the bed all the way to the back. I then carefully push a 2.5 hex tool (my nice rc one with handle) from the bottom upwards through the ptfe tube being careful to keep it centered and not gouging the tube. This pushes the blockage up and out through the top. Works like a charm. Sometimes I have to push the clog back and forth to get it freed up...use a piece of filament to push it down and hex tool to push it up etc etc.. Don't push filament up through the bottom when hot obviously.

This next tool part could probably be done best with the unit cooled down but it's quick enough to keep things flowing and not wait...for me anyway.

Hope this helps. Only clogged twice but it's extremely annoying and frustrating when it happens. Color print seems to be the culprit when it unloads the filament at high temps and seems faster then usual?? Or I'm just imagining. Anyway the process works to remove the clog

Re: My method of clearing the filament stuck in heat break

Here's my 2 cents on this....

I bought some cheap filament on amazon that prints great but would jam on filament change everytime i would switch them. It would lodge a glob in the bottom of the heatbreak and wouldn't let the new filament load, my extruder motor would start skipping.

So i did like everyone else and let it cool down and start disassembly. After the third time i got frustrated. I came up with a shortcut. Let the printer cool down then flip it on its side. Remove just the nozzle and you will see the clog. I then take a straightened paper clip and heat the end till hot with a lighter. Then just poke out the clog clearing the hole and pulling it toward you. Replace the nozzle and do the loading routine (preheat and load as usual). Thats it 5-10 minutes max and your back to printing...

Also updating the fw to 3.0.7 helped alot and the unload feature is way faster which has completly eliminated my jamming problems.

Hope this helps.

Re: My method of clearing the filament stuck in heat break

Thank you, that really helped. Cheers.

Re: My method of clearing the filament stuck in heat break

I've always used eSun cleaning filament when switching out different filaments. I have had a clog once, and this cleaning filament cleared it.

and an 8 inch (200mm) or greater caliper is recommended.

Re: My method of clearing the filament stuck in heat break

so the whole idea is it because you take off 2 fan and preform the preheat, so even the heat break area will not enough to melt the stucked filament too right? with the fan attached we will not able to do the same as you do ( preheat and use another filament to push it out)?

Re: My method of clearing the filament stuck in heat break

Your method will not address the problem.

Let's say you print with ABS or PETG.

You can clear the jam with your method, but once you print with PLA you will get a jam.

The issue is you have a higher temp filament artifacts left in the nozzle which will cause the clog when going to a lower temp. filament.

What is causing the jam?

- Do you change filament types with out doing the atomic method / cord pull method?

- Do you pre-heat and leave the printer idle at printing temps before starting the print?

I have two printers. The MK2 has not jammed so far after using about 6 spools of PLA.

The other printer has jammed once, and that was due to switching from PETG to PLA without doing enough cord pulls.