layers "move" away when changing rotation direction

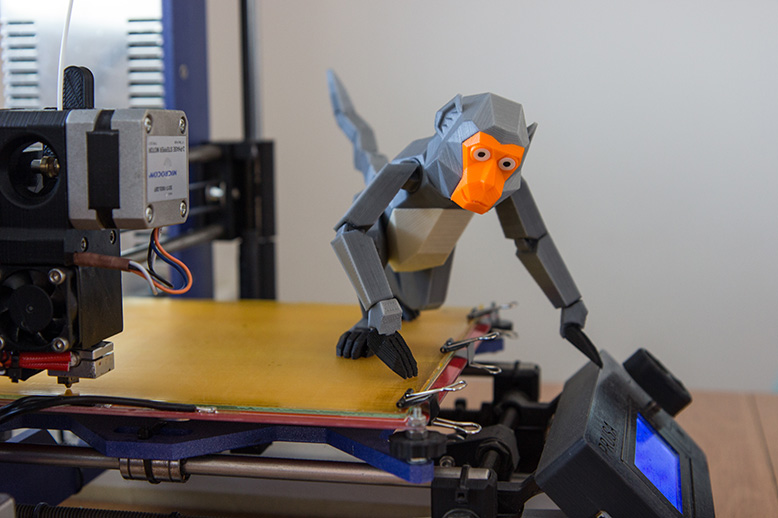

Hi guys. So I am printing some parts which is circular in center. Here is picture

as you can see in first half layer is everything fine and printhead is moving counterclockwise. Then You will notice layer slip and perfect finish afterwards. What happens here is printer starts to print not continuous circles but splitting them in half due to shape of part. By printing two regions separately print head moves in other direction when printing inside-part perimeters. I see that one corner of print slips inside and other moves further. Whole slipping pattern angles 45 degrees to my printbed and part. What can possibly cause this? I read that loosen belts, but mine are tight I bought it preassembled. Recalibrated but still the same issue. Some more pics.

http://shop.prusa3d.com/forum/download/file.php?mode=view&id=5246

http://shop.prusa3d.com/forum/download/file.php?mode=view&id=5247

http://shop.prusa3d.com/forum/download/file.php?mode=view&id=5248

Re: layers "move" away when changing rotation direction

forgot to mention, that what's strange that outer oval perimeter doesn't slip at all. It is uniform and good quality,

Re: layers "move" away when changing rotation direction

ok, today I rotated model 90 degrees on build plate. "slided" pattern changed position on model, remaining the same sliding position on build plate meaning that this is mechanical problem not slicer or file.

Any thoughts?

Re: layers "move" away when changing rotation direction

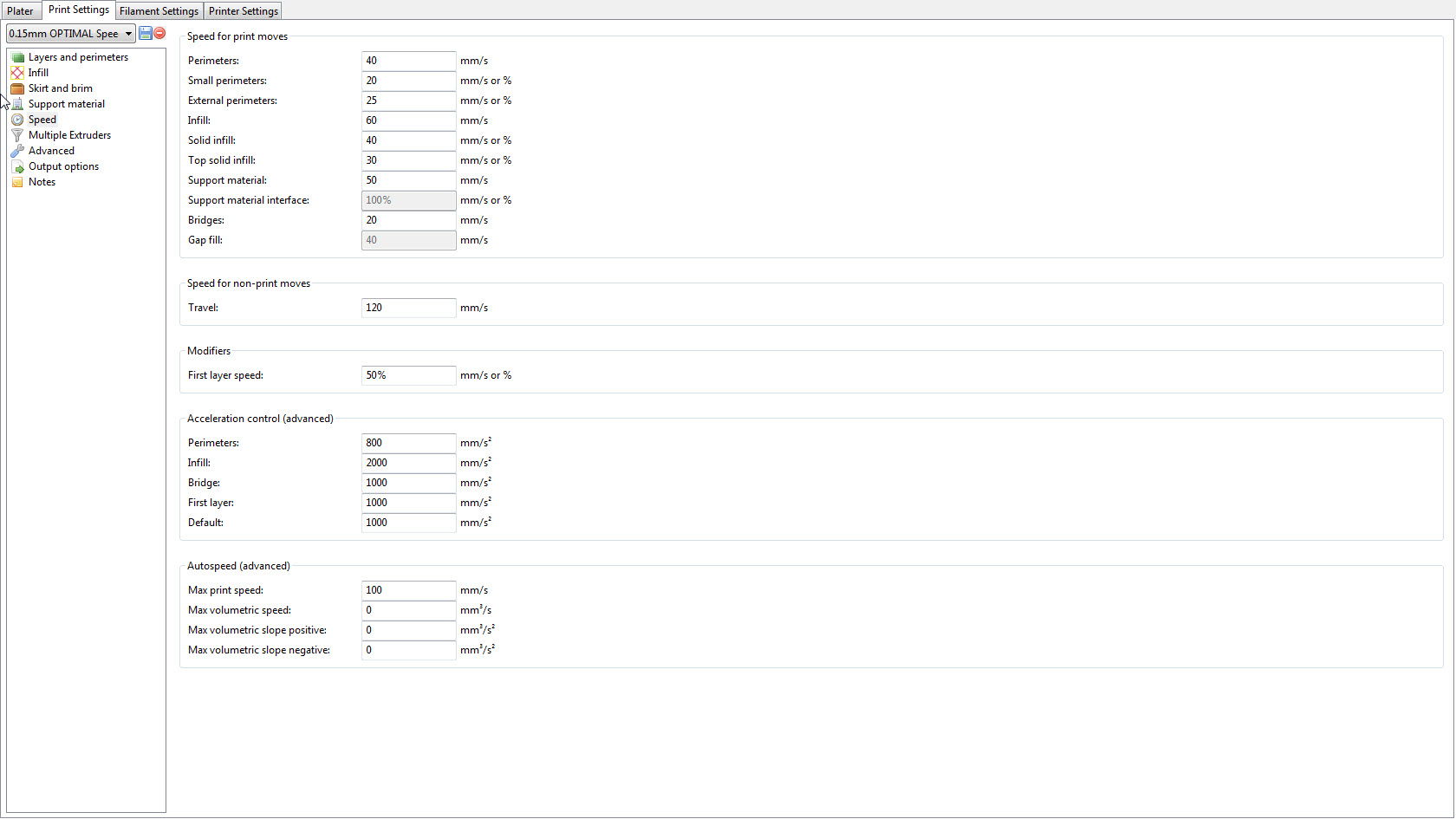

strange, tried Cura as slicer and sliding goes away. Overall print quality way worse than Slic3r but slipping stopped. Trying simplify 3d now.

Re: layers "move" away when changing rotation direction

None of your photos show up, maybe that's why no-one replied so far.

Re: layers "move" away when changing rotation direction

in my opinion it seems to be a slicer (not printer) problem.

have you checked the single layers in preview mode ?

dem inscheniör is' nix zu schwör...

Re: layers "move" away when changing rotation direction

yep it's definetly slicer. Simplify3d prints also good but with weird gaps between shell perimeters (3 perimeters). Althou problematik area seems to be when swiching from radial printing to C shape printing. I dont understand why this is problematic area actually.

Yes in slicer preview everything seems super duper. :/

Re: layers "move" away when changing rotation direction

ok have some news. Unfortunatelly it was not slicer. First results with Simplify 3D was much better than with Slic3r or with Cura, unfortunatelly problem not disapeared and printing thiner objects resulted in gaps between layers (not gaps in Z axis, but in X-Y). By carefull examination of printer mechanics I came up with following observations (need to mention that I am an engineer so I know something here):

First of all it's amazing product and I hope that my observation will make this printer even better after upgrades by Prusa.

1. drive puley and freewheel puley arent the same diameter resulting in belt being tensioned to triangular shape when bed near Y motor. This results in bed non linear movement, it accelerates.

2. Y axis freewheel holding bolt is not suitable because freewheel with ball bearing have a lot of axial play and bolt itself have too much thread resulting in ball bearing sitting partially on thread partially on solid bolt. This results in non perpendiculat position of freewheel.

3. Belt needs to have passive tensioner, existing system with belt holding itself by tooths gives too less or too much of tension.

4. Freewheel puley must be with tooths like drive puley. When given proper tension to the belt, belt's tooth starts to amortisate, also scewed freewheel position enhances problem.

5. X axis the same problems, plus extruder belt holder seems to be off belt movement axis too. It is by ~0.5mm further to display side.

6. Linear bearing to loose

7. just get rid of belts and put rods everywhere (like in Z axis) like high durability and precision CNC mashines are made.

8. extruder too heavy or holding rods too soft/poor construction resulting in non constant Z height and vibrations. In my oppinion spacing rods futher apart would solve problem a little, another suggestion thicker rods.

Overall it is very nice mashine with some mechanical issues that can be corrected.

After experiments with belt tension on different axis I finally get good results and no more oval instead of circle for me. It was problem of 0.5mm in 133mm circle. I now have pretty good results but for how long. I bet that belts will soon worn off and problems reappear.

p.s. this was not hate related post, I hope that my observations will give much to think for others finding their problems or ideas of upgrading this product. Meanwhile I will start looking for more precise mashine with more rigid frame and axis management.