Important miniRambo Head Bed connector information

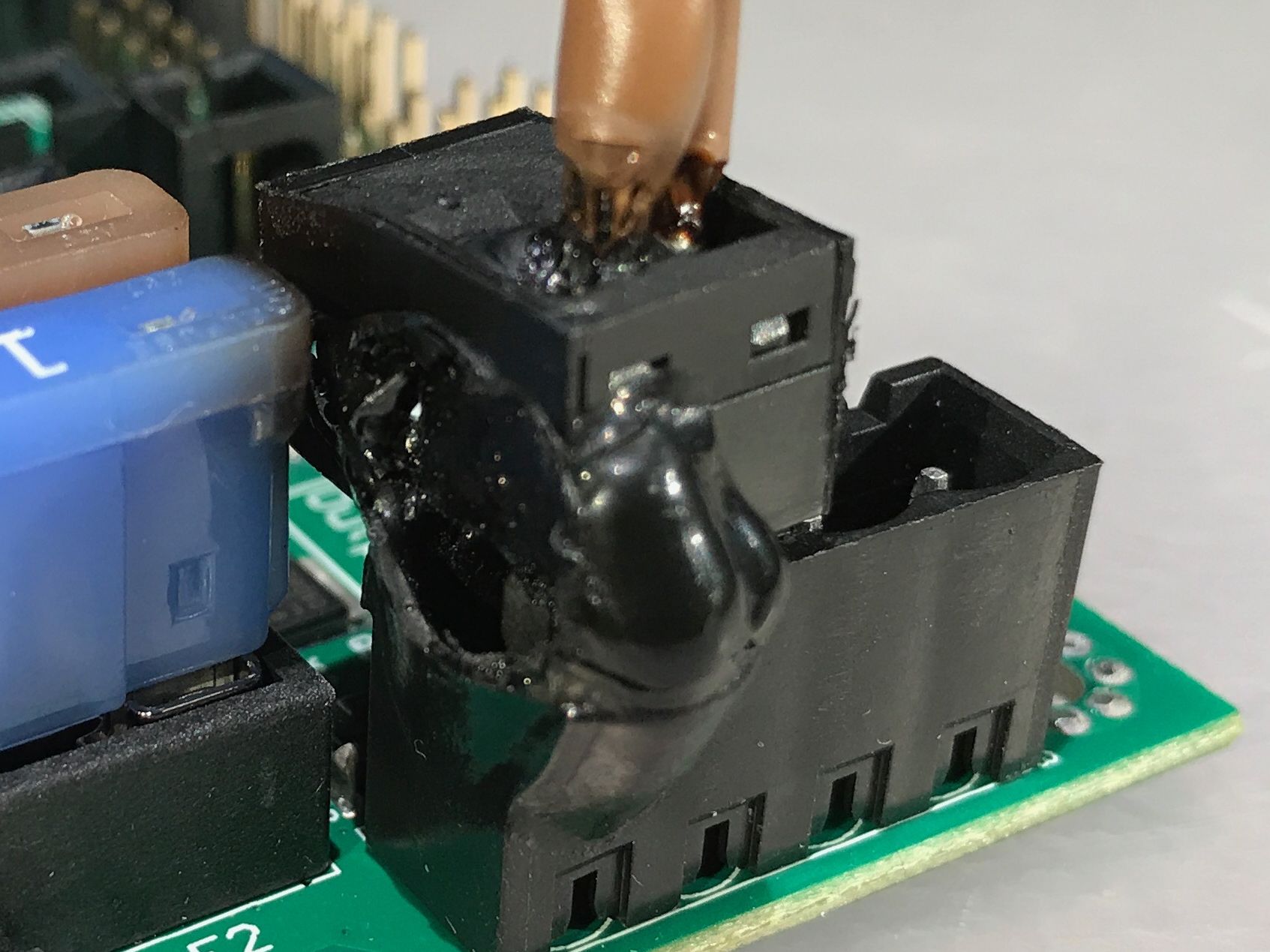

After my recent miniRambo Heat Bed connector meltdown. I contacted Ultimachine and asked what causes this problem and how to prevent it in the future. Hopefully, this helps someone in the future. Here is the answer they sent me.

Melted connectors are usually attributed to one of four assembly issues:

1. Insufficiently torquing the terminal screw is the most common cause. The 039530 series terminal blocks used on Rambo have a maximum torque rating of 5lb-ft. Depending on the wire used the recommended torque is around 24lb-in. These should basically be as tight as possible with a full-size screwdriver. The average human will not be able to over tighten them with a standard screwdriver. If insufficiently clamped the wires eventually loosen and arc, melting the connector.

2. A common issue is for the wires to not be properly constrained. The wires should be secured so that there is no movement where the wire enters the connector. If a wire is repeatedly bent it can work itself loose from the connector or break strands, increasing resistance and heat. This causes a chain reaction of more resistance and heat until the connector finally fails. Preferably there are at least two constrained points (wire ties?) between the connector and any potential movement in the wire.

3. Another less frequent mistake is constraining the wires in a way that applies force to the connector. This binds the connector and only allows it to make a partial connection. Again resulting in increased resistance and heat.

4. Wire selection is the other critical point. This is not likely a problem for you since I am assuming your kit came with the proper wire for the application. If there are more than a couple degrees of temperature rise in the wire it is likely undersized.

5. If you have had previous issues you should inspect the wire end. If there is carbon or discoloration it needs to be cut back to a clean section.

Re: Important miniRambo Head Bed connector information

I had this issue over the weekend. I decide to solder the wires to the back of the Rambo board, that seems to be the recommended fix of the issue.

The solder wasn't the best, but it seems to have worked. I'm testing over the next few days ramping up the heat the temp and checking the connection.

Everything seems OK so far.

Re: Important miniRambo Head Bed connector information

i would recommend screw-cage clamp principle terminal blocks from the PTR AK700 series. they are rated for a max. current of 24A (our MK42 heatbed draws 15A). of course, you need to reroute the cables then.

with every high current connector that you just "plug in", you'll risk a meltdown like documented in the picture.

the technical data for the heat bed connector used at our pre-assembled heatbed and the rambo is sometimes given with a rated current of 15A, but sometimes only with 12A as well. so even if the higher value is valid: here we are at the edge of the specification and the risk of failure is always given.

soldering the cables directly to the board is a solution as well. but if the soldering joint isn't perfect (which is very likely if you haven't got the right equipement and more important: well trained soldering skills), it won't last long and bears the risk of overheating as well (which might cause that the connection unsolders itself).

dem inscheniör is' nix zu schwör...