help with print

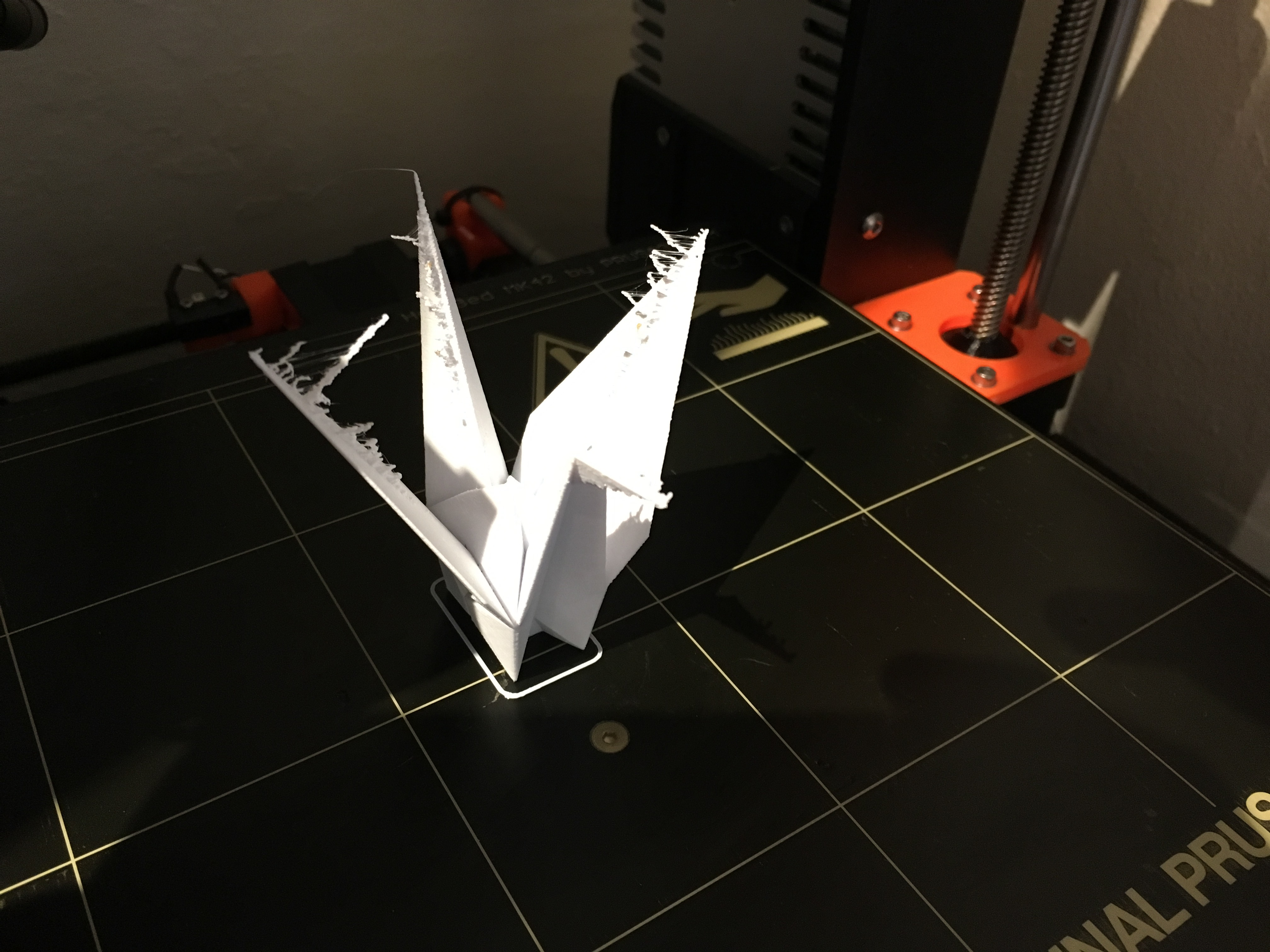

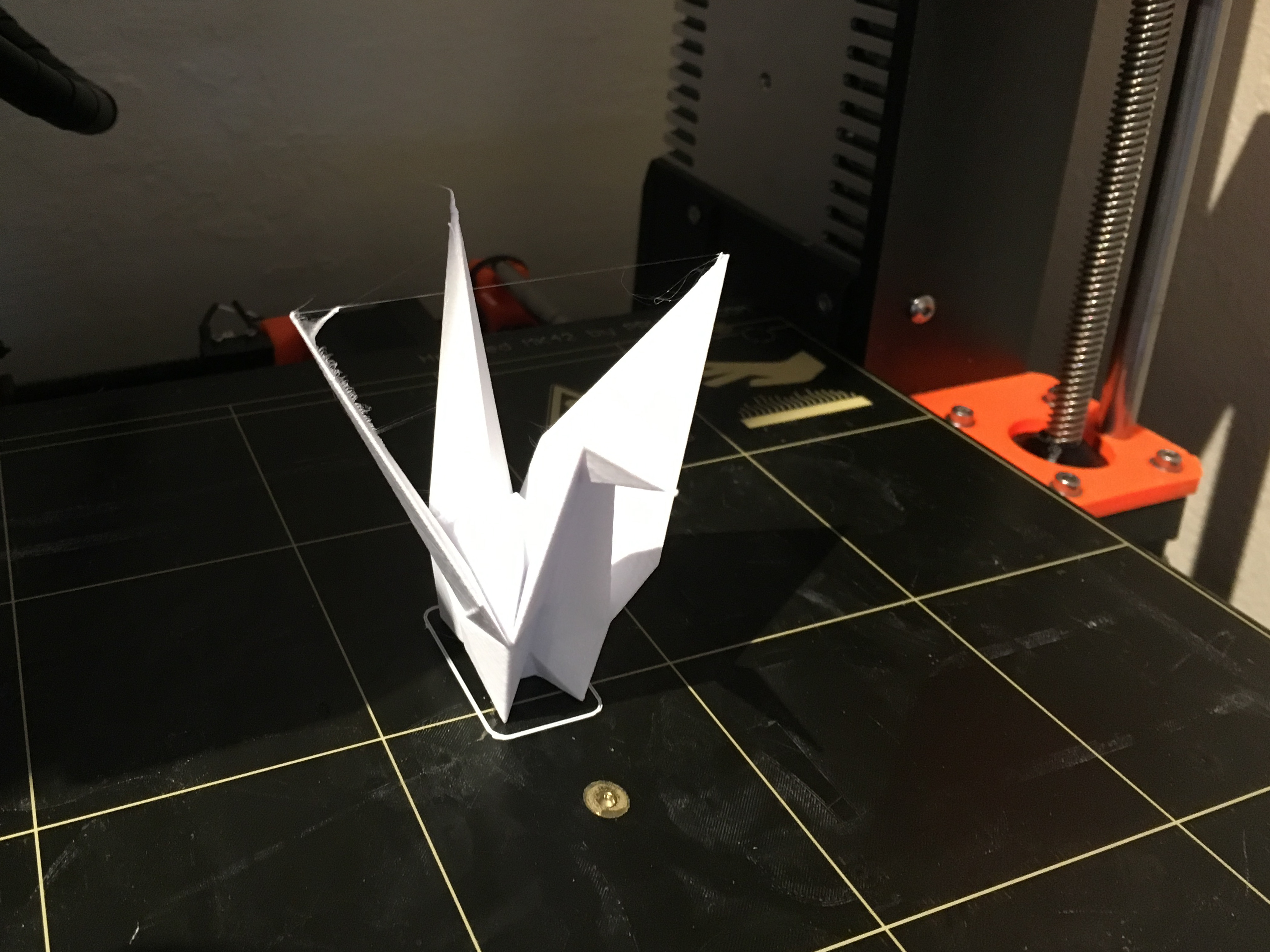

I printed this origami crane using Slic3r:

http://www.thingiverse.com/thing:541095

I have never had this happen before, and no real problems like this. What am I doing wrong for the slic3r options?

The beginning of the gcode contains:

; generated by Slic3r 1.30.0.25-prusa3d-release_candidate_1_3-win64 on 2016-06-22 at 19:27:28

; external perimeters extrusion width = 0.30mm

; perimeters extrusion width = 0.30mm

; infill extrusion width = 0.50mm

; solid infill extrusion width = 0.30mm

; top infill extrusion width = 0.30mm

M107

M83

M104 S210

M140 S55

M190 S55

M109 S210

G28

G92 E0.0

G1 X60.0 E9.0 F1000.0

G1 X100.0 E12.5 F1000.0

G92 E0.0

G21 ; set units to millimeters

G90 ; use absolute coordinates

M83 ; use relative distances for extrusion

G1 E-0.80000 F2100.00000

G1 Z0.200 F12000.000

G1 X115.724 Y98.334 F12000.000

G1 E0.80000 F2100.00000

G1 F2076.444

Re: help with print

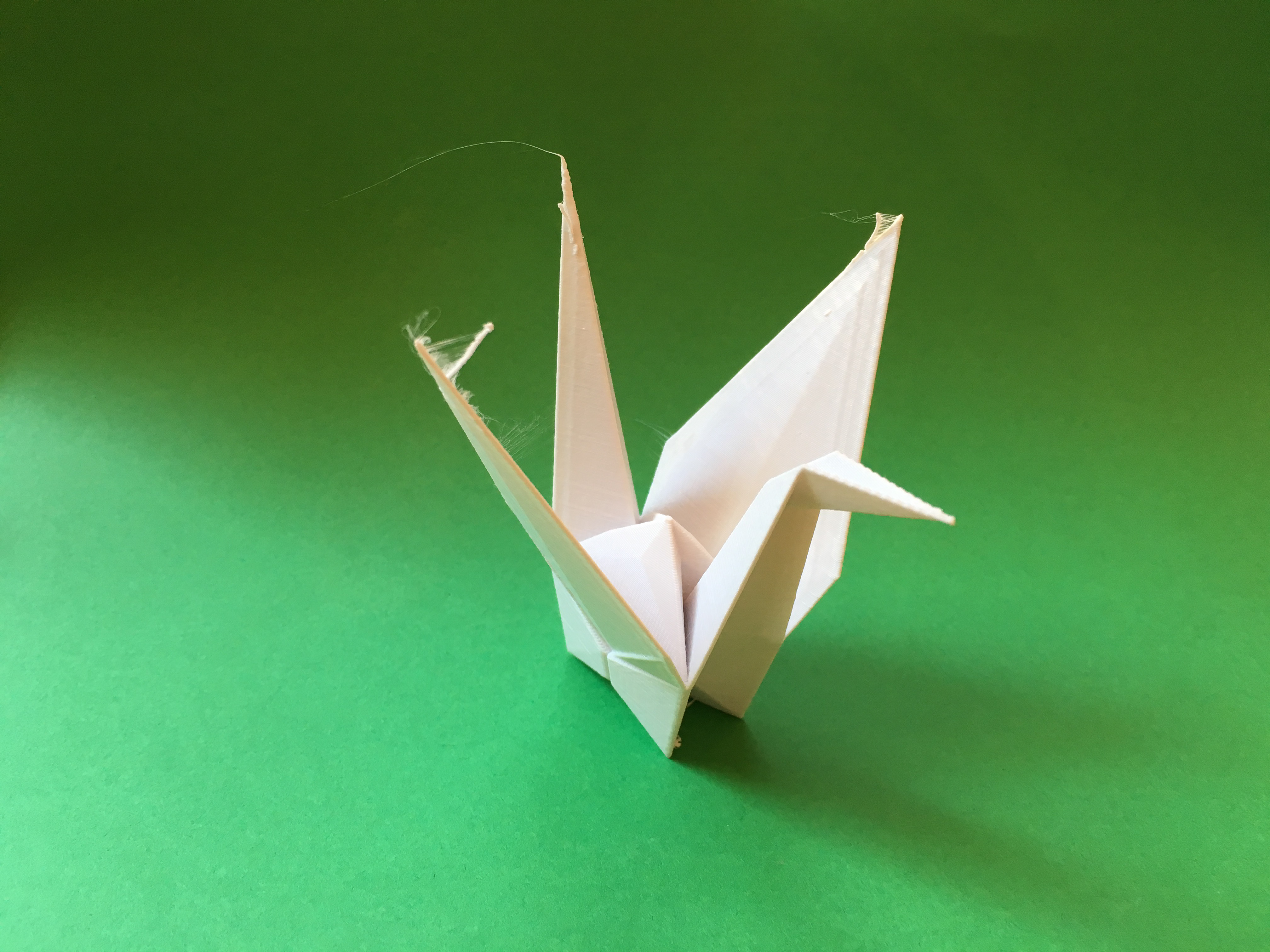

That's "just" stringing I think, what temperature do you have at your nozzle? And what does your retraction settings look like?

http://support.3dverkstan.se/article/23-a-visual-ultimaker-troubleshooting-guide#stringing

Me on MyMiniFactory!

Me on Instagram

3D Printing Live Feeds

Prusa MK2 Usergroup Slack Live Chat

Unofficial live chat by users for users.

Re: help with print

I think (but am not certain) that there may be a clue here:

; external perimeters extrusion width = 0.30mm

; perimeters extrusion width = 0.30mm

Is that the setting for a 0.25mm nozzle? Sorry, I don't use Slic3r; it just looks wrong. I extrude at nozzle width or up to 20% greater. Never less than nozzle width.

I think all the settings used are at the end of the GCode file.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: help with print

I think (but am not certain) that there may be a clue here:

; external perimeters extrusion width = 0.30mm

; perimeters extrusion width = 0.30mm

Is that the setting for a 0.25mm nozzle? Sorry, I don't use Slic3r; it just looks wrong. I extrude at nozzle width or up to 20% greater. Never less than nozzle width.

I think all the settings used are at the end of the GCode file.

I resliced it and you are right. Came out much better, thanks.

; generated by Slic3r 1.30.0.25-prusa3d-release_candidate_1_3-win64 on 2016-07-05 at 08:44:09

; external perimeters extrusion width = 0.45mm

; perimeters extrusion width = 0.45mm

; infill extrusion width = 0.45mm

; solid infill extrusion width = 0.45mm

; top infill extrusion width = 0.40mm

...

; filament used = 4100.4mm (9.9cm3)

; avoid_crossing_perimeters = 0

; bed_shape = 0x0,250x0,250x210,0x210

; bed_temperature = 55

; before_layer_gcode =

; bridge_acceleration = 1000

; bridge_fan_speed = 100

; brim_width = 0

; complete_objects = 0

; cooling = 1

; default_acceleration = 1000

; disable_fan_first_layers = 1

; duplicate_distance = 6

; end_gcode = M104 S0 ; turn off temperature\nM140 S0 ; turn off heatbed\nG1 X0 ; home X axis\nM84 ; disable motors

; extruder_clearance_height = 20

; extruder_clearance_radius = 20

; extruder_offset = 0x0

; extrusion_axis = E

; extrusion_multiplier = 1

; fan_always_on = 1

; fan_below_layer_time = 100

; filament_colour = #FF14E2

; filament_diameter = 1.75

; first_layer_acceleration = 1000

; first_layer_bed_temperature = 60

; first_layer_extrusion_width = 0.42

; first_layer_speed = 60%

; first_layer_temperature = 210

; gcode_arcs = 0

; gcode_comments = 0

; gcode_flavor = reprap

; infill_acceleration = 2000

; infill_first = 0

; layer_gcode =

; max_fan_speed = 100

; max_print_speed = 100

; max_volumetric_speed = 0

; min_fan_speed = 85

; min_print_speed = 15

; min_skirt_length = 4

; notes =

; nozzle_diameter = 0.4

; only_retract_when_crossing_perimeters = 0

; ooze_prevention = 0

; output_filename_format = [input_filename_base].gcode

; perimeter_acceleration = 800

; post_process =

; pressure_advance = 0

; resolution = 0

; retract_before_travel = 1

; retract_layer_change = 1

; retract_length = 0.8

; retract_length_toolchange = 3

; retract_lift = 0

; retract_lift_above = 1

; retract_lift_below = 199

; retract_restart_extra = 0

; retract_restart_extra_toolchange = 0

; retract_speed = 35

; skirt_distance = 2

; skirt_height = 1

; skirts = 1

; slowdown_below_layer_time = 25

; spiral_vase = 0

; standby_temperature_delta = -5

; start_gcode = M83\nM104 S[first_layer_temperature]\nM140 S[first_layer_bed_temperature]\nM190 S[first_layer_bed_temperature]\nM109 S[first_layer_temperature]\nG28\nG92 E0.0\nG1 X60.0 E9.0 F1000.0\nG1 X100.0 E12.5 F1000.0\nG92 E0.0

; temperature = 210

; threads = 4

; toolchange_gcode =

; travel_speed = 120

; use_firmware_retraction = 0

; use_relative_e_distances = 1

; use_volumetric_e = 0

; vibration_limit = 0

; wipe = 1

; z_offset = 0

; dont_support_bridges = 1

; extrusion_width = 0.45

; first_layer_height = 0.15

; infill_only_where_needed = 0

; interface_shells = 0

; layer_height = 0.2

; raft_layers = 0

; seam_position = nearest

; support_material = 0

; support_material_angle = 0

; support_material_contact_distance = 0.05

; support_material_enforce_layers = 0

; support_material_extruder = 1

; support_material_extrusion_width = 0.35

; support_material_interface_extruder = 1

; support_material_interface_layers = 2

; support_material_interface_spacing = 0

; support_material_interface_speed = 100%

; support_material_pattern = rectilinear

; support_material_spacing = 1.5

; support_material_speed = 50

; support_material_threshold = 40

; xy_size_compensation = 0

; bottom_solid_layers = 3

; bridge_flow_ratio = 0.95

; bridge_speed = 20

; external_fill_pattern = rectilinear

; external_perimeter_extrusion_width = 0.45

; external_perimeter_speed = 30

; external_perimeters_first = 0

; extra_perimeters = 0

; fill_angle = 45

; fill_density = 10%

; fill_pattern = grid

; gap_fill_speed = 40

; infill_every_layers = 1

; infill_extruder = 1

; infill_extrusion_width = 0.45

; infill_overlap = 0.05

; infill_speed = 60

; overhangs = 0

; perimeter_extruder = 1

; perimeter_extrusion_width = 0.45

; perimeter_speed = 40

; perimeters = 2

; small_perimeter_speed = 20

; solid_infill_below_area = 0

; solid_infill_every_layers = 0

; solid_infill_extruder = 1

; solid_infill_extrusion_width = 0.45

; solid_infill_speed = 40

; thin_walls = 0

; top_infill_extrusion_width = 0.4

; top_solid_infill_speed = 20

; top_solid_layers = 4

Re: help with print

Sorry, again I don't know Slic3r, but is this another clue:

; ooze_prevention = 0

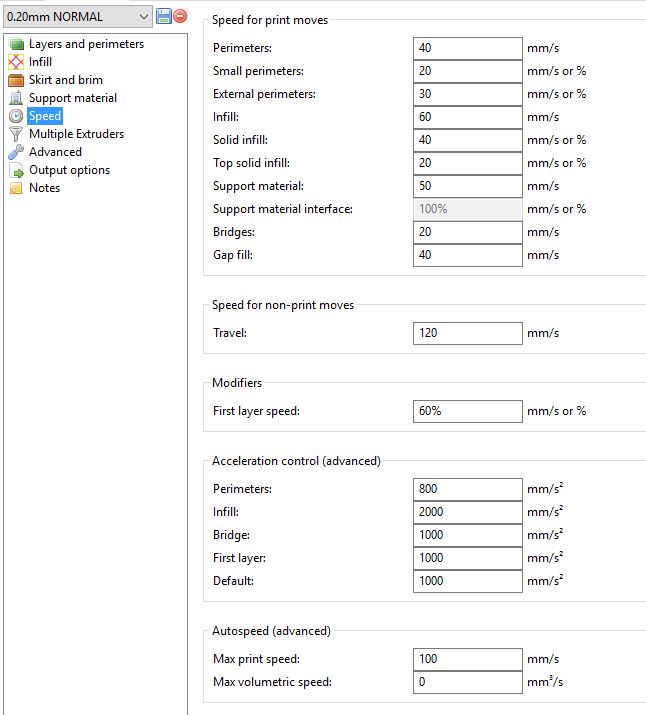

Also are you using Z-Hop? You could reduce retraction. Increase travel speed. Slow down print speed. Is wipe turned on?

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: help with print

Sorry, again I don't know Slic3r, but is this another clue:

; ooze_prevention = 0

According to popup help that is for use with multiple extruders.

Also are you using Z-Hop?

No.

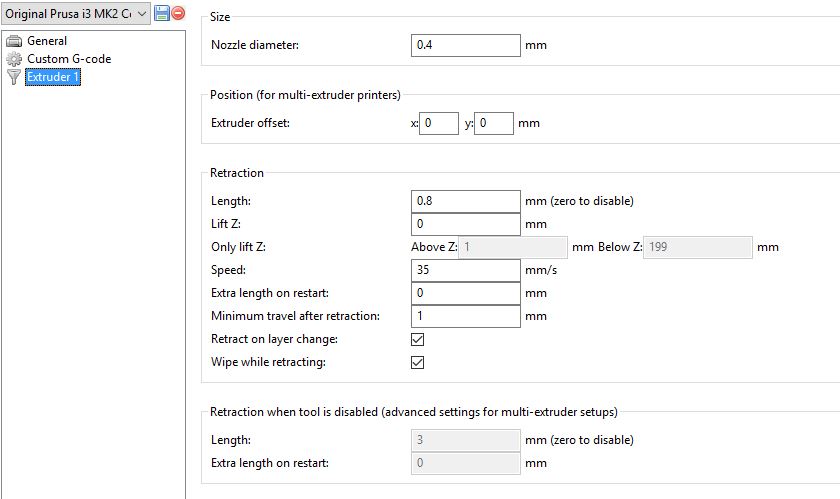

You could reduce retraction.

I don't see that option in Slic3r settings.

Increase travel speed. Slow down print speed.

There are so many speed option I wouldn't know where to start. See below.

Is wipe turned on?

I don't see that option either.

Re: help with print

You can find those options in the Printer Settings tab and then select Extruder 1

Re: help with print

Reduce retraction length to 0.5mm, increase retraction speed to 40mm/s.

This may help; it may not. Trial and error...

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: help with print

Now reduce the temperature try 195 to 200 degrees.

Basically, you have oozing on a move. We need to prevent that so wipe and move as quickly as possible (the retraction is now quicker so less ooze).

Most PLA materials can easily be printed at 180 degrees (or lower). The higher the temp, the runnier it becomes and therefore more potential for ooze.

You could also try reducing the extrusion width to the same as the nozzle width (0.4mm). That will leave less pressure in the nozzle and again less ooze.

Peter

EDIT: is that glue on the bed? Or is the bed just not very clean? If it's glue, then FWIW, I prefer to use a brim for extra adhesion as removing hte glue from this bes is messy...

And you could try increasing your travel speed to 150mm/sec

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: help with print

I guess you're the 3D printing whisperer.

No, not at all. I often get it all very wrong. There are many forum members here who know a lot more than I do.

The thing is, I started 3D printing by buying a Chinese clone. I had no support, no knowledge and no profiles. I was given a link to Pronterface and Slic3r (an early version).

I didn't like them and then I stumbled across Cura. That was a lot more simple and I learned a lot from it, but the quality was not great. I found KISS and found that the prints were significantly better quality, but I still had to learn to use it and to set up my own profiles, finding out and understanding what each one did.

I don't like to wait for my prints, so I do try to push the printers hard and fast, but there are many models which need to be printed very slowly. I have 2 printer profiles in the slicer; one regular and one for fast printing.

Most of the time it is possible to tell what settings to use just by looking at the model in the slicer and it is usually quite easy to see what settings need tweaking by looking at a photo of a model, mainly because I have had similar results at some point in time...

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…