Firmware 3.0.10 just released!

Woot!

https://github.com/prusa3d/Prusa-Firmware/releases/tag/v3.0.10

3.0.10 firmware for Prusa i3 MK2

@PavelSindler PavelSindler released this 3 hours ago

3.0.10 firmware for Prusa i3 MK2

This is final version of 3.0.10 firmware. This version fixes issues in previous version 3.0.10-RC1. For detailed desription of all features see also https://github.com/prusa3d/Prusa-Firmware/releases/tag/v3.0.10-RC1

Summary:

Loose pulleys test added

Statistics fixed

PID tuning fixed and saving parameters to EEPROM enabled

Stop print function fixed

Load filament function improved

Stack guard added

Xyz calibration updated

Factory reset has new menu

Missing "Move Z" option fixed

Improved messages in Italian and Spanish languages

German language added

Description of changes with respect to 3.0.10-RC1:

Loose pulleys test:

Selftest was sometimes indicating that Y pulley is loose even in case that it was not true. This has been fixed. Auto home was added at the end of selftest procedure. This leads to predictable behavior when moving axis after selftest was run.

Statistics fixed:

Total print time were not displayed correctly in some cases and number of hours displayed could be higher than 24. It has been fixed. There is no need to reset statistics data to display total print time correctly.

Languages:

Spanish messages were improved and initial version of German language was added.

Live adjust limitation

Live adjust is now limited to range from -10 mm to 0 mm. This should prevent setting live adjust values to excessive values and decrease heatbed damage probability.

Gcodes checking added

Some invalid gcodes caused undesirable printer behavior (stopping imidiately, invalid serial response). This has been fixed.

The loose pulleys check looks pretty cool.

Re: Firmware 3.0.10 just released!

Updated 😀

Works perfect, no problem, test running good from scratch, no belt issues :geek:

Thomas

Re: Firmware 3.0.10 just released!

How does one update the firmware from Linux? avrdude? Are there instructions somewhere?

- Gab

Re: Firmware 3.0.10 just released!

How does one update the firmware from Linux? avrdude? Are there instructions somewhere?

I upgraded last night from my RPI3 running Linux (and octoprint)

$ avrdude -c stk500v2 -b 115200 -p atmega2560 -v -P /dev/ttyACM0 -D -U 1_75mm_MK2-RAMBo13a-E3Dv6full.hex

Worked fine (make sure your user have access to the serial port, or run avrdude as roo)

Re: Firmware 3.0.10 just released!

OctoPrint has a Firmware Updater plug-in ...

Re: Firmware 3.0.10 just released!

The new firmware is great! Love the new M500 feature (which can save your PID tuning settings). For reference, here's the command I used to upgrade it from a Raspberry Pi (Octopi):

avrdude -C /etc/avrdude.conf -v -p atmega2560 -c wiring -P /dev/ttyACM0 -b 115200 -D -U flash:w:1_75mm_MK2-RAMBo13a-E3Dv6full.hex:i

(The example posted previously wasn't working for me--needed those extra "flash:w:" and ":i" parameters)

Also, here's how to tune your PID settings so you get a nice consistent (flat) temperature when printing (seriously, do this! It's worth it!)... Run these commands from the "terminal" tab in Octoprint after upgrading your firmware:

PID Autotune (make sure your hot end is cold before running!):

M303 E0 S200 C8

That will heat up the extruder to 200°C ("S200") 8 times ("C8") and finally report the result like so:

Recv: bias: 57 d: 57 min: 198.42 max: 202.32

Recv: Ku: 37.21 Tu: 20.64

Recv: Classic PID

Recv: Kp: 22.33

Recv: Ki: 2.16

Recv: Kd: 57.62

Recv: PID Autotune finished! Put the last Kp, Ki and Kd constants from above into Configuration.h

Now use those settings to both apply the PID values and save them:

M301 P22.33 I2.16 D57.62

M500

Replace "P", "I", and "D" values with the "Kp", "Ki", and "Kd" values reported from the autotuning function. The "M500" above is the new feature in the 3.0.10 firmware that tells it to save the settings for subsequent prints/boots.

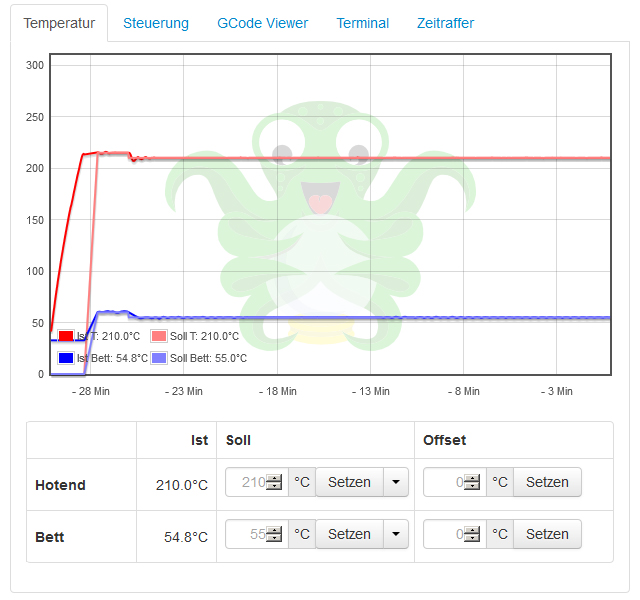

You should now have consistent (flat) temperatures during your prints. No more 3-4° temperature swings!

Re: Firmware 3.0.10 just released!

If final release 3.0.10 Firmware, why is it not on front page under http://www.prusa3d.com/drivers/ ?

Last update/release was back in November 2016 and a 3.09 build.

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: Firmware 3.0.10 just released!

No more 3-4° temperature swings!

Was 6-7 degrees for me. Now it's nice and steady. But only the hot end PID saved to EEPROM. The bed heater PID didn't persist through a reboot.

Re: Firmware 3.0.10 just released!

❓ should the pid tuning process be started with or without filament in the nozzle ?

➡ i mean: a loaded hotend will probably deliver different values than an empty one, due to the thermal capacity of the filament (which adds to the heated mass).

so i guess it should be done with filament.

so i guess it should be done with filament.

has anyone tested if the differences in the thermal capacity of the filaments lead to different Kp, Ki & Kd values ?

dem inscheniör is' nix zu schwör...

Re: Firmware 3.0.10 just released!

But are PID tuning values temperature specific?

What happens if you tune and store PID settings to ROM for PLA, then decide to print ABS?

Re: Firmware 3.0.10 just released!

💡

pid tuning is a way to determine the specific parameters for a feedback control system or lets better say: a closed loop system.

the three key parameters describe the behaviour of the system when you deal with it and try to control its reactions.

➡ so if there is a perceptible influence of the filament to the parameters, then you are right and you need "in theory" different values for different materials.

btw.: the influence is not particular the temperature itself, it's the thermal capacity that the filament adds to the closed loop system with it's mass and capability of cooling down the nozzle.

:geek: i don't know if this influence is really measurably, but from the theoretical point of view it has to be taken in account.

dem inscheniör is' nix zu schwör...

Re: Firmware 3.0.10 just released!

If final release 3.0.10 Firmware, why is it not on front page under http://www.prusa3d.com/drivers/ ?

Last update/release was back in November 2016 and a 3.09 build.

My guess is that they are waiting for the final release of Slic3r as well...

- Gab

Re: Firmware 3.0.10 just released!

If final release 3.0.10 Firmware, why is it not on front page under http://www.prusa3d.com/drivers/ ?

Last update/release was back in November 2016 and a 3.09 build.

My guess is that they are waiting for the final release of Slic3r as well...

well that just released too

https://github.com/prusa3d/Slic3r/releases/tag/version_1.33.4

Re: Firmware 3.0.10 just released!

I do the PID Autotune.

Now temperature is about +/- 2 degrees. Is this OK ? ❓

Thomas

Re: Firmware 3.0.10 just released!

Oh my. What brought that on. Posted new firmware on driver page!

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: Firmware 3.0.10 just released!

😛 wow, this pid tuning worked pretty well !!!

😕 in the past i used to have a temperature deviation of approximately +/- 3°C... which didn't bother me that much, because my prints weren't visibly degraded by temperature swings.

🙄 in octoprint i always saw a nice oscillation around the temperature set.

now i checked out the new pid tuning inside the 3.0.10 firmware.

after the 8 tuning cycles, i got the following result at the terminal:Recv: bias: 98 d: 98 min: 196.84 max: 203.57

Recv: Ku: 37.08 Tu: 24.58

Recv: Classic PID

Recv: Kp: 22.25

Recv: Ki: 1.81

Recv: Kd: 68.35

Recv: PID Autotune finished! Put the last Kp, Ki and Kd constants from above into Configuration.h

Recv: ok

then i stored the values with: M301 P22.25 I1.81 D68.35

M500

inside the eeprom.

now the nozzle of my mk2 holds the temperature dead straight :mrgreen:.

only during the settling time, i encounter a very tiny swing in (with a deviation below +/- 1°C)... and then: straight line.

❗ that's awesome, i'm pretty impressed ❗

the guys that developed that feature really know how to control a closed loop system.

by the way: does this work for the heated bed as well ?

M303 E-1 S100 C8

I do the PID Autotune.

Now temperature is about +/- 2 degrees. Is this OK ? ❓

Thomas

seems that it can get better ....

dem inscheniör is' nix zu schwör...

Re: Firmware 3.0.10 just released!

Knickohr wrote:

I do the PID Autotune.

Now temperature is about +/- 2 degrees. Is this OK ? ❓

Thomas

seems that it can get better ....

dem inscheniör is' nix zu schwör...

How ?

Thomas

Re: Firmware 3.0.10 just released!

...

How ?

Thomas

maybe the values haven't been stored correctly ?

octoprint sometimes looses the connection (due to timeout) to the printer.

just repeat the whole process a 2nd time.

btw. just started the whole pid tuning process for the heated bed. but i guess it'll take a lot more time than tuning the hotend.

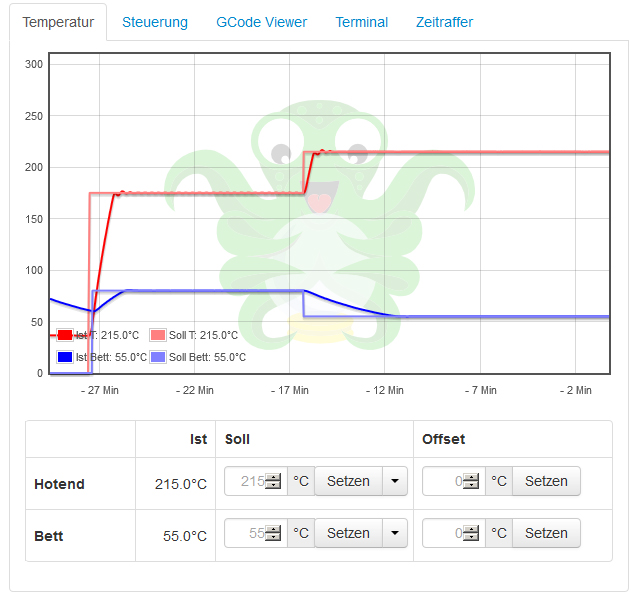

update: yeah, pid tuning for the bed works too:

M303 E-1 S100 C8

delivered after a while the following output (the last one, don't use the generated output while the tuning process is still running):

[...]

Recv: bias: 193 d: 61 min: 99.59 max: 100.43

Recv: Ku: 183.73 Tu: 40.80

Recv: Classic PID

Recv: Kp: 110.24

Recv: Ki: 5.40

Recv: Kd: 562.17

Recv: PID Autotune finished! Put the last Kp, Ki and Kd constants from above into Configuration.h

Recv: ok

[...]

now i stored the values afterwards with:

M304 P110.24 I5.40 D562.17

M500

to test the new pids, i set the nozzle temperature to 175°C and the bed temperature to 80°C. in this combination i encountered a small oscillation of the hotend temperature of +/- 0.2°C. i bet that's because the additional current required to get the heatbed up to the 80°C lets the voltage of the power supply drop by some milli-volt, which affects the pid's for the closed loop of the hotend (but that's some kind of pettifoggery now).

after i've set the temperature to the pla default settings, bed and nozzle temperature got dead straight:

dem inscheniör is' nix zu schwör...

Re: Firmware 3.0.10 just released!

I didn't use Octoprint, I use Proterface 😕

Thomas

Re: Firmware 3.0.10 just released!

Just to echo another post. If I run the calibration for 200c PLA save and then run it for 230c PETG. Will one overwrite the other or are they both saved as individual values in the eeprom. I tend to switch from PETG to PLA to composites PLAs like SainSmart Wood, Bronze. I clean my nozzle with eSun Cleaner Filament between filament changes. I have people I print for and they tend to like different materials. I want to venture into using NinjaFlex and want everything to function as best it can. Seems like this PID tune could help. My temp vary -/+ 3-4. But sometimes when having the temp change from 210(First layer) to 200 (All other layers) It will drop as low as 194c before it goes back up to 200c.