Filament stuck in cold end all the way up to top of heatsinks

Hey all,

So I managed to get my hot end jammed to the point where there is filament all the way up to the top of the heat sinks and after trying a few things, I am at a loss as to how to get the filament out of there.

Here is as quick a rundown as I can give, without leaving out anything important, of the comedy of errors that led up to this. I was printing with formfutura easywood coconut filament and the nozzle clogged during a print. The easywood is very runny at temperature and previously when this had happened I had just taken some PLA and fed it through to force the clog out. This time that did not work. The easywood is very brittle, so I figured it might have broken off in the heat break when I removed it right after it clogged and that there might not be anything clogging the actual nozzle like the last two times it had jammed. Thus I then followed the procedure in the link below, which had worked for me twice before, to try and clear the heat break (this was with hindsight an exquisitely stupid thing to do at this point since I had not yet inserted a metal wire into the nozzle to dislodge the clog).

When that inevitably didn’t work, instead of trying to remove the filament at temperature like I should have done, I decided to try a cold pull. Unfortunately all the sources I found via google at the time said to do the cold pull at 90 degrees. This was along the lines of what I remembered doing with my other printer a couple years ago that had a much different hot end design so it seemed reasonable to me. I did not see the trouble shooting guide on the Prusa website that said to do it at 160 until about 10 minutes ago. Thus the cold pull went about as disastrously as it could have with the filament snapping off right at the top of the set of heat sinks where the Teflon tube emerges from the cold end. At this point I finally stuck a wire up the nozzle which did indeed dislodge the initial clog. I then tried to feed filament through but with no success. I realized that by trying to dislodge the filament from the heat break first, I had caused what filament was there to expand and stick to the Teflon tube. I then after more research on the e3d v6 hot end tried following the above procedure again at 225 degrees for an extended time (about an hour) to try and see if there was a point where the heat would creep far enough up the heat sinks to dislodge the blockage and let me ram the rest through. It did not work. But by the time I called it quits the filament I was ramming in there at the top of the heat breaks was getting soft which means, if I understand PLA’s thermal properties, there is bloated filament stuck in there all the way up.

From what I can tell, the only thing left to do at least on paper is disassemble the e3d v6. But from what I understand, it must be heated to around 280 degrees during disassembly as well as the last steps of assembly and I have no work bench or clamps to hold it that would allow me to do this safely. I also have no heat gun or torch to try to burn the filament out, and I have no thermal paste to be able to put it back together correctly afterward.

So all that having been said, what are my options? Would it be safe to try the procedure in the link at a higher temperature for longer or would I likely melt the abs extruder assembly? Is there anything else to try that might work or am I going to have to buy another hot end?

Re: Filament stuck in cold end all the way up to top of heatsinks

Had the same problem (different causes) - see here http://shop.prusa3d.com/forum/original-prusa-i3-mk2-f23/nothing-is-extruded-t4807.html .

Basically raise the assembly on the Z axis and heat the thing and disassemble it BUT leave the cables on. Take care to not touch the hot-end (the bottom part).

Read also this one http://shop.prusa3d.com/forum/original-prusa-i3-mk2-f23/filament-completely-stuck-in-hotend-t1873.html and contact support.

Good luck!

Re: Filament stuck in cold end all the way up to top of heatsinks

if the parts are still in the extruder housing and it's a mk2 or mk2s, remove the part cooling fan duct,

heat the hot end for ABS, when hot, hold the heatsink still with a 17mm spanner, taking care not to damage the heater of thermistor wiring,

then use a 7mm spanner to remove the nozzle.

at this point, while the heater is still hot, you could try pushing the filament out again from the top.. if the nozzle was blocked with foreign matterr, you may find that it clears now

if not.

let everything cool down

dissassemble the extruder housing to expose the heatsink.

remove the cable ties and undo the wrapping on the cable bundle, at the back of the x carriage, loosen all of the cables,ease the heatsink and hot end out of the housing and whilst holding the heat blocks till with a 17mm spanner, unscrew the cooling fins, this should expose the PTFE Liner and remaining filament...

the PTFE Should pull off the remaining filament, leaving a stub of filament in the heat break assemble in the hot end...

make sure that the cold end fan is safe, the blades are very fragile.

now you can either replace the heatbreak, or try to melt the filament out by heating the hot end and pulling on the filament,

or take the heat break out and try to melt the filament out with a hot air blower / electric paint stripper, cigarette lighter, gas cooker...

(be very careful, it will all get hot... )

you can also replace the nozzle or try and melt the blockage out to re use the existing nozzle.

assuming you have now cleaned everything, you can re assemble everything leaving the heatsink half a turn loose. I suggest you replace the PTFE tubing with a new piece which has been chamfered a little with a pencil sharpener at the bottom, make sure the PTFE is fully inserted and the little black retaining ring is lifted away from the heatsink, to seat the PTFE Properly in the heatbreak, and then screw the heatbreak into the cold end heatsink, to slightly compress the PTFE tube.

screw the nozzle fully into the heat block and back it off 1/4 turn, screw the heatbreak into the heat block until it is tight against the nozzle, and then heat the hot ens to 255 degrees, and when hot use two spanners to tighten the nozzle into the heatsink so that it's tight against the end of the heatbreak...

reassemble your printer making sure that the cables are:

1, in a slightly different place to the original installation, to try and utilise a different portion of cable, immediately behind the X carriage, where all of the bending takes place, This may save you having to repair a broken cable in the near future, make sure that the cables are all snug in the slots in the X carriage and cable tied / wrapped properly. so that they don't interfere with movement of the x carriage,

and then try out the printer again.

best of luck...

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Filament stuck in cold end all the way up to top of heatsinks

Hi all... I think I have the same problem.

I am new to this site and to 3d printing, I just got my printer Prusa i3 Mk2 about two weeks ago, thing are going good, I have had some good results so far.

I have been using slic3r Prusa edition that came recommend with the printer using mostly default settings, using only PLA.

However, I have been having a reoccurring problem. I first noticed it when some of my prints were failing due to the filament getting chewed up and the extruder stops extruding and was due to a blockage. The extruder motor will just skip and skip and not push any PLA through and I also cannot push any through manually.

I cleared the first blockage by heating the printer to the ABS setting (255) and kept hitting load filament setting (Without actually trying to load any filament) and poked a needle up the extruder tip. The needle easily went up the tip about an inch before it met resistance, then I just poked around a bit until the PLA started flowing again, and once it did a “Lot” of filament came out, much more then would be expected if it was just a nozzle jam. Which lead me to realize that PLA was getting jammed a good ways up inside the heating block.

So I done a lot of research online and played with different settings in Slic3r for temperature and printing speeds:

• I measured and re-entered the PLA to 1.71mm on average, calibrated the extrusion a little and uped it to a multiplier of 1.02 as it extruded about 2mm short during testing.

• I slowed the print speeds down

• I increased the temperature 218

• And I told it to only retract when crossing parameters. (this made the biggest difference).

This worked a little, but I still run into the problem and my heating block is clogged again, and now I cannot get it clear the way I did last time. However, I am going to give the methods a go which were talked about in these two threads:

So, I am going to try and unclog the heating block today trying these methods.

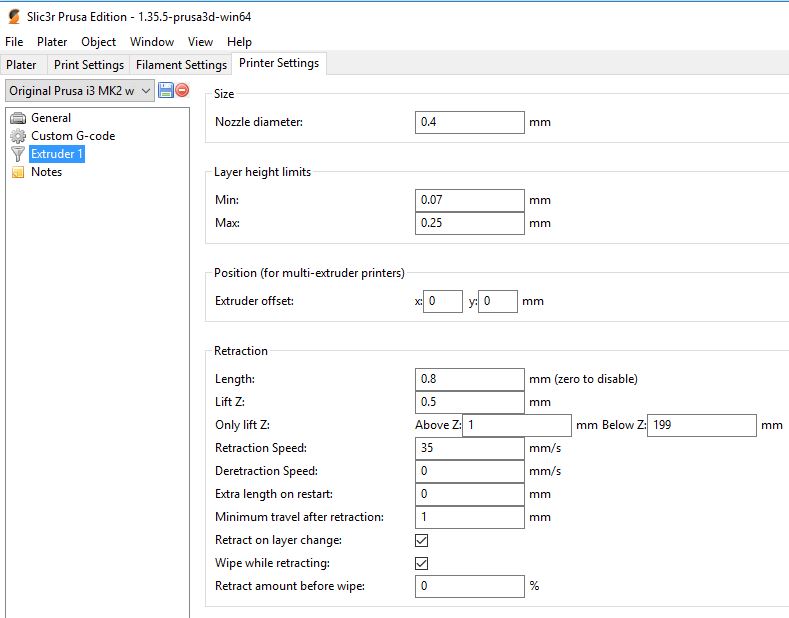

Finally, I believe that I am having this problem due to the retraction settings, I feel like retraction is happening to aggressively, especially during infill stage, despite slowing down the print speed. I have been trying to find where is Slic3r Prusa edition to change these setting and how to make it less aggressive, but I cannot find a clear answer to this question… “Where do I change the retraction setting, it slic3r, and how do I lower it so that it is not as aggressive. (i.e is 0.6 lower then 0.8, or vis versa, and where do I enter these numbers?)

Re: Filament stuck in cold end all the way up to top of heatsinks

So, I started to pull the heatblock apart and as I took off the cooling fins I noticed that a piece of filament was stuck into the Nylon tube. This was a long piece of filament and I had a very hard time pulling it out. Finally, I had to heat up a needle and melt it into the filament wait for it to cool and pull hard on It with plyers to get it out.

Now, I am not sure what would cause this, but what I think is going on is that the aggressive retraction setting are acting like a plunger and pulling melted PLA up into the nylon tube where it is cooling and getting to thick to push back down into the extruder nozzle and heating block (which was very clean). Do you guys think that this is what is going on… or do I have another problem causing this. I really need to find out how to change the recreation settings.

Re: Filament stuck in cold end all the way up to top of heatsinks

This could be retraction based issue. Are you usilg slic3r prussa edition?

If so. I would expect the retract settings to be correct... regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Filament stuck in cold end all the way up to top of heatsinks

Yes, I am using the Prusa Slic3r edition which I downloaded and installed about two weeks ago. The prints that I have been having problems with are the ones which have a lot of quick retractions, all of my print falls have been due to filament jams. I think that I need to slow these retractions down, but can seem to located where in Slic3r I do this and what to slow it down too at the moment.

Re: Filament stuck in cold end all the way up to top of heatsinks

try this page

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Filament stuck in cold end all the way up to top of heatsinks

Thank you for the screen shot, I am going to give it a go tonight and see how it works out!

Re: Filament stuck in cold end all the way up to top of heatsinks

Looks like i have the set up for the multi extruder model. I am showing 4 extruders each with a retraction of 4mm at a speed of 50mm/s

Re: Filament stuck in cold end all the way up to top of heatsinks

Not good. Try resetting.

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Filament stuck in cold end all the way up to top of heatsinks

Thanks for the help! I updated Slic3r and then deleted the 3 extra exruders listed and set the retraction to your settings and have been running off prints every since, even the ones that were failing.

Re: Filament stuck in cold end all the way up to top of heatsinks

Progress!

best wishes Troy,

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Filament stuck in cold end all the way up to top of heatsinks

Thank you guys so much for your answers!!! Glad that it looks like I'll be able to fix it with the tools I have! Studying for my calc exam has consumed my life for the last few days so I hadn't had a chance to check the forum and I won't have time to try your suggestions until after my exam, but I am going to go ahead and order some tubing, thermal paste, and a heat break just in case I need to replace both. Do you have any additional advice for when I go to put the nozzle back on? I absolutely love how little this hot end oozes and I want to ensure that when I put it together again that it works just as fantastically as it did before all this happened.

Thanks,

Matt