Difficulties to find the proper adjusments with a new PLA spool

Hi,

I have just finished my first spool of PLA with good results, the live Z was -310 microns and the extruded plastic was slightly squished,and with a good /reasonable adhesion to the bed. I am using JeffJordans calibration routine during the adjustment sequence.

The problem is that now with a new spool of PLA from a different manufacturer, I have difficulties to find the proper adjustment for live Z in a range such -500 / - 300 microns. The best results are around - 360 but the print sticking is not sufficient and isn't improved around -400 / - 450. Moreover the print is not uniform on the 70 X 70 mm test pattern in most of the tests.

Note that I have made a full re-calibration and still use IPA 90% for cleaning. I have noted too that the fan works from time to time during the printing.

Is that possible, for the same type of filament, to have such differences ? Could it be due to the selected temperatures ( I still use -215°-205°C / 55°C ) ?

Re: Difficulties to find the proper adjusments with a new PLA spool

Try increasing the temperature for the first layer.

I don't think that the Z adjustment is filament dependent. However the temperature certainly is, and things like actual filament diameter will affect adhesion as well (eg underextrusion).

- Gab

Re: Difficulties to find the proper adjusments with a new PLA spool

HI,

Thanks for reply.

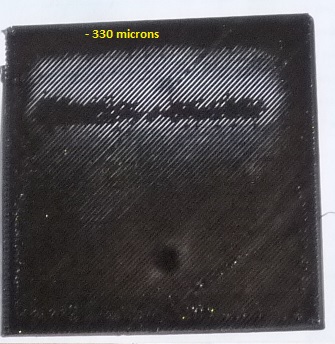

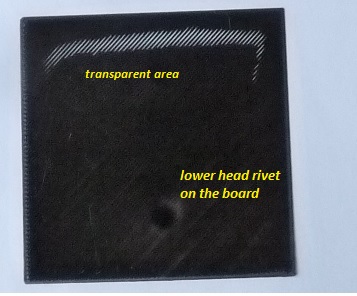

In the mean time I did some more tests ( same T° as previously) and as you say, the Z adjustment doesn't seem to improve the situation. The image is taken with z = -330 microns and shows a large transparent area and if I use -360 microns no basic change. I was hoping to do not see anymore that transparent area, the nozzle being closer to the be, but no effect.

I am going to test various temperatures. Do I have to keep the same bed temperature ?

Re: Difficulties to find the proper adjusments with a new PLA spool

- I made several tests at a fixed live Z = -320 microns ( close to the one for the first PLA spool ) . Temperatures variations : from 200°C up to 230 ° ( PLA data : 190° / 225°C ).

- Results : no major improvment. 220/224 ° seem a bit better but with quite the same transparent area shown previously. It's surface decreases around 224° and increases with higher or lower T°.

- Two remarks :

- That transparent area appears always at the same place ( upper part of the ~75x75 mm image ) with the same values for all parameters during the printing ( checked on the LCD display )

- It is in some way difficult to get the so called "Elephant foot" problem. I got it with my first spool ( too much squish onto the bed, with wider lines and then too much adhesion). Stephan.k proposed to raise a bit the nozzle and then no more problem !

Today on the contrary, poor adhesion and a transparent surface even if I the nozzle go closer to the bed at various different temperatures ....

Note : I don't know if it is of any importance or not but only the extruder fan works during the printing. The printing fan doen't work or from time to time. It's speed can be adjusted in the settings but having no information that parameter remains to 0. The automatic check test shows that it is OK.

Any need to adjust a value, is it controlled by the electronics ?

Re: Difficulties to find the proper adjusments with a new PLA spool

The part fan (ie. the one in the front) should not be on for the first layer.

You may try increasing the bed temperature as well, but I don't think that's the issue. Have you checked the filament diameter? It looks a lot like an extrusion problem to me, but, I may be wrong.

- Gab

Re: Difficulties to find the proper adjusments with a new PLA spool

- OK for the printing fan, the Z live tests are related only to the first layer !

- I have increased by 10 to 20% the bed T° but no changes.

- I confirm the 1,75 mm filament diameter... I have unloaded the filament and reloaded it but nothing new. The usage of the nozzle corresponds to only one spool ( 1Kg). To your knowledge could it be obstructed by very fine debris coming from that first spool ( Prusa filament ) ?

Re: Difficulties to find the proper adjusments with a new PLA spool

That seems unlikely, but since having spare nozzles around is a good idea anyway, if you're out of ideas you could try replacing the nozzle.

Is the filament flowing normally or do you notice anything weird wrt extruder motor and pulley? Maybe try to change the spring tension for the extruder idle as well?

I'm not sure what else to suggest, hopefully others have better ideas.

- Gab

Re: Difficulties to find the proper adjusments with a new PLA spool

Nothing special concerning the flow of the filament ! I have some mechanical parts and I don't see a big change although the "JeffLordan" test shows always a transparency in the upper part ( like in the image of the first post) . I suppose that even if the bed is a bit inclined the Z calibration takes care of it ?

By the way how do you determine the correct "position" of the spring tension ( plastic support / head of the screw # 13 mm ) no indication in the Prusa doc, may be not so important ?

I have no spare nozzle for the moment and try first to find the bug ! It happened when I change the spool to another one so it seems due to this operation ?

Thanks anyway...

Re: Difficulties to find the proper adjusments with a new PLA spool

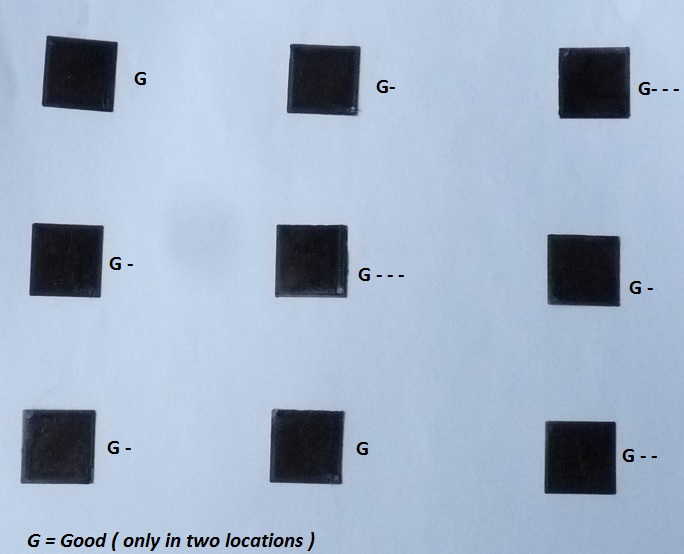

The mesh bed leveling is not perfect, so maybe the bed is lower at that spot. Try moving that square around or print an array of squares.

It's very hard to get the first layer perfect across the whole bed, usually one stops at "good enough".

- Gab

Re: Difficulties to find the proper adjusments with a new PLA spool

Slice and print the attached.

Get the centre square correct using Live Z and then set the outside squares using the level adjust.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Difficulties to find the proper adjusments with a new PLA spool

Hi,

Thanks Gab and Peter,

- Tests results of the cal-squares pattern: not so bad in the corners but worse in the center ( see image1 ). I say worse in terms of aspect ( not regular )

- I did at the same time a test in the center with the JeffJordan pattern : always a transparent area. ( image 2 )

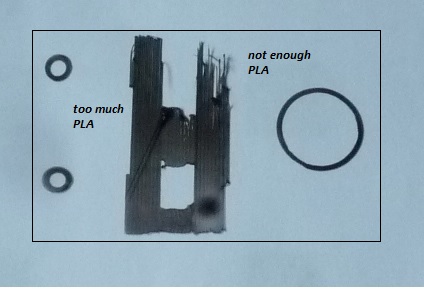

- If I start printing a mechanical part, problems occur at the very beginning ( image 3 ): it seems that the nozzle when arriving at the end of a scan leaves either not enough PLA or too much PLA and then when it comes back at the same place, the nozzle heurts the material and create localy an excess thickness etc.

Please see the following post I have difficulties with next attachments...

Re: Difficulties to find the proper adjusments with a new PLA spool

Hi again,

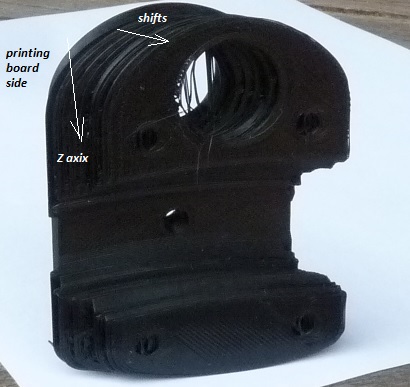

- I succeded ( in some way ) to have a not so bad start of the print but another problem occured : a severe shift of layers after a while, the gcode looks good ???

Concerning the first layer problem, I feel that the central area of the board creates now problems, could the central surface be deteriorate ?

Re: Difficulties to find the proper adjusments with a new PLA spool

I just ran into the shifting issue (along the Y-axis, towards the rear of the printer) myself, and was able to resolve it by disassembling, cleaning and re-installing the bed, rods and bearings, and then adjusting the belt.

It seems that my Y-axis rods dried out and the bearings collected some dirt, which caused them to roll unevenly. Clean the rods, add a light coat of oil and reassemble. Make sure all your zipties are nice and tight.

Unfortunately, you'll need to re-calibrate the XYZ and Z offsets once you've done this.