ABS Calibration cube tummy tuck

Hi all,

Been getting pretty good results printing PLA but I would like to start printing ABS/Nylon for stronger parts, (rc planes).

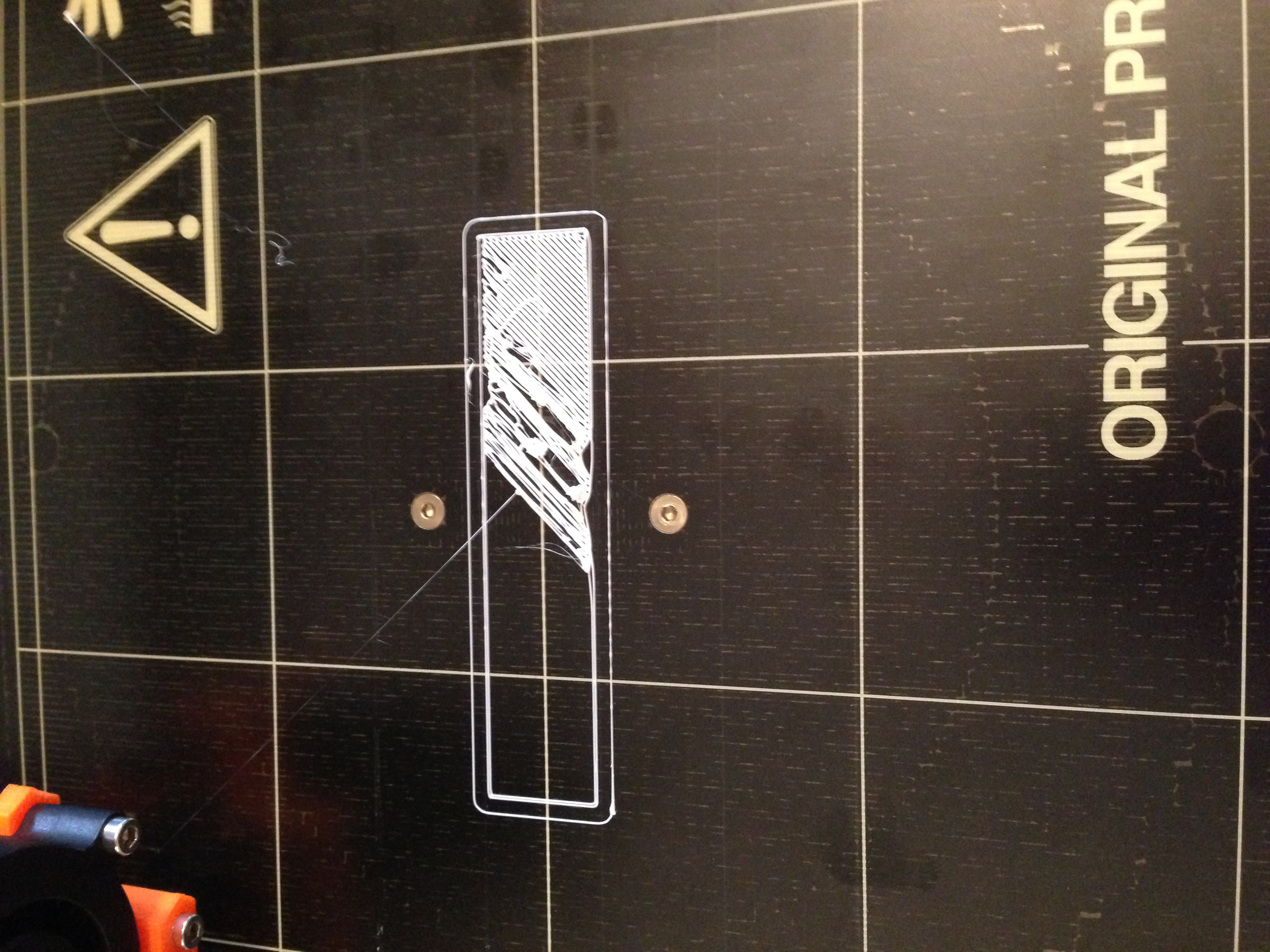

I have built an enclosure which came out great but ABS/Nylon are kicking my butt at the moment. I have been trying to print a calibration cube 20mm x 20mm x 20mm with 2mm walls. Hopefully I'll attach some pictures of the issue, with ABS anyway.

Firstly my settings:

Cali' cube #1:

Extruder - multiplier @ 1.00 manual at 0.40mm width.

First layer: 95% height. 100% width and 45% speed (print speed at 1500mm/min [25mm/sec])

Used a brim at 2 layers x 7 outlines - tried this as first prints just came straight of the bed.

Temps' - Hotend @255 and bed @ 100

Fan - Off

Temp inside the enclosure reached around 39 degrees C by end of print, around 40 minutes.

Hopefully you can see the walls of the cube bow in, the inside of the cube the walls are straight. There is warping of the base also.

Cube #2 settings are;

Extruder - Multiplier @ 0.95 Auto width @ 0.48 - Tried reducing extrusion as the first cube had walls around .150mm too thick.

First Layer: 95% height, 105% width (tried to squash the thing down, 45% speed (Print speed set to 1400mm/min [23mm/sec]) thought that might help with the deformation.

Temps' - Hotend @ 250 and bed @ 100

Fan - Off

Again temp within the enclosure got to around 39 degrees C.

I'd appreciate any advice on what is causing the "Tummy tuck". I'm thinking I went the wrong way with cube #2 and I should have increased the extrusion multiplyer beacuse as I sit here typing this I noticed the walls of both cubes a straight on the INSIDE and only bowed on the OUTSIDE.

I'd also appreciate advice on the warping. I've re-done the Z calibration and achieve very good sticking with PLA. I have even put some Kapton tape on the bed. I tried with glue stick and hair spray (how do women get that stuff out of there hair!) still get the warping.

Any advice greatly appreciated.