200 micron vs 100 micron

Hi,

I've run into a curious problem. My Mk2 has been printing like a champ for weeks.

This evening, a buddy sent me an STL for to print. A simple little 10 minute print job.

For giggles I configured to print at 100 microns, PLA, no supports, pretty easy print. In fact, except for the 100 micron part, exact same settings and filament I was using two nights ago for some good prints.

My machine couldn't do the 100 microns. The skirt would fail or be stringy, in one case it picked up the piece and dragged it around the bed. I had been running in silent mode, which I hear can under power some of the steppers and cause issues, so switched back to high power, and still no luck.

I change the resolution to 200 micron (no other change, using Simplify3D BTW) and it prints like butter. totally flawless.

I suddenly remembered I had an issue with a sub 200 micron print awhile ago and eventually switched resolution to 200 but forgot to look further into the issue.

If you change resolution are there other settings that need to be changed? Any other thoughts what the problem might be to help me troubleshoot?

Cheers!

Kevin

Re: 200 micron vs 100 micron

If you change resolution are there other settings that need to be changed? Any other thoughts what the problem might be to help me troubleshoot?

➡ yes, that's why there are different "profiles" in the settings for slic3r and simplify3d*).

first: layer#1 always needs to be 200µm or more. another point is that you usually need to print with less infill as with lower resolution. you need more bottom and top layers. sometimes you have to reduce the extrusion width.... a good idea is to add a z-hop in case of retraction.

:geek: it's some real kind of science, to figure out the perfect settings for thinner layers. just reducing the layer height will fail in most cases.

*) the problem with simplify3d is, that you need to be careful when experimenting with different settings. you can easily mess them up by prompting that you want to store the changes (when you close s3d). so it's always a good idea to get back to the genuine fff-file for the settings. i prefer the original prusa i3 mk2 RC4 factory file, that josef posted here at the forum.

dem inscheniör is' nix zu schwör...

Re: 200 micron vs 100 micron

Actually your problem is a machine firmware setting.

The minimum first layer height this printer can manage is 0.15mm simply because the firmware will not allow the nozzle to go any lower so that it cannot melt the PEI sheet.

Set the first layer height in your slicer of choice to 0.15mm (or greater) and the remaining layers to 0.1mm.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: 200 micron vs 100 micron

Actually your problem is a machine firmware setting.

The minimum first layer height this printer can manage is 0.15mm simply because the firmware will not allow the nozzle to go any lower so that it cannot melt the PEI sheet.

Set the first layer height in your slicer of choice to 0.15mm (or greater) and the remaining layers to 0.1mm.

Peter

the limits are set inside the 1_75mm_MK2-RAMBo13a-E3Dv6full.h or let's better say the Configuration_prusa.h:

// Home position

#define MANUAL_X_HOME_POS 0

#define MANUAL_Y_HOME_POS -2.2

#define MANUAL_Z_HOME_POS 0.15

// Travel limits after homing

#define X_MAX_POS 250

#define X_MIN_POS 0

#define Y_MAX_POS 210

#define Y_MIN_POS -2.2

#define Z_MAX_POS 210

#define Z_MIN_POS 0.15

don't know what happens if you lower the Z_MIN_POS to 0.10 ? i guess you might get some issues if your printbed isn't very even. when you travel the extruder manually (lcd -> settings -> move axis ...), the meshbed leveling does not take effect.

dem inscheniör is' nix zu schwör...

Re: 200 micron vs 100 micron

Tried a quick test before I head out to work.

Used the FFF file @JeffJordan referred to and used the default High resolution setting. Still had the same issues printing.

I know I've printed high res in the past. At the very least some of the test models that ship with the printer are high res and they came out fine.

I haven't upgraded to the latest firmware yet (the one from last month). So I may as well take this opportunity to update the firmware, re-run calibration, reset my live-z and see if that sorts me out.

Thanks for the assist.

Re: 200 micron vs 100 micron

did you print abrasive filament in between the last weeks ? might be that your nozzle has worn out a little bit.

dem inscheniör is' nix zu schwör...

Re: 200 micron vs 100 micron

did you print abrasive filament in between the last weeks ? might be that your nozzle has worn out a little bit.

Nope. I've been printing with Colorfabb nGen a fair bit lately. I don't believe that is abrasive at all. When not using nGen then it has been PLA.

Re: 200 micron vs 100 micron

Actually your problem is a machine firmware setting.

The minimum first layer height this printer can manage is 0.15mm simply because the firmware will not allow the nozzle to go any lower so that it cannot melt the PEI sheet.

Oh, that's why i have to lower my "Live Z Adjust" when i want to print a 0.1mm first layer. I learn a thing, thanks.

Re: 200 micron vs 100 micron

Actually your problem is a machine firmware setting.

The minimum first layer height this printer can manage is 0.15mm simply because the firmware will not allow the nozzle to go any lower so that it cannot melt the PEI sheet.

Oh, that's why i have to lower my "Live Z Adjust" when i want to print a 0.1mm first layer. I learn a thing, thanks.

I had thought live-Z was a set-it-and-forget-it thing. Set after calibration and your done. So I need to re-adjust when I change resolution?

Re: 200 micron vs 100 micron

Actually your problem is a machine firmware setting.

The minimum first layer height this printer can manage is 0.15mm simply because the firmware will not allow the nozzle to go any lower so that it cannot melt the PEI sheet.

Oh, that's why i have to lower my "Live Z Adjust" when i want to print a 0.1mm first layer. I learn a thing, thanks.

I had thought live-Z was a set-it-and-forget-it thing. Set after calibration and your done. So I need to re-adjust when I change resolution?

No. Your first layer should never be lower than 0.15mm, otherwise you may damage the PEI sheet.

Set the first layer height in the slicer to at least 0.15mm (0.2mm for better adhesion) and the remaining layers to whatever you require.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: 200 micron vs 100 micron

So just a little update.

After what @PJR mentioned finally got through my thick skull, I tried using Slic3r to run a print instead of Simplify3d.

Slic3r has the option for setting first layer height, where as Simplify3d does not (you have to use multi-processes to have different config for different layers).

Even with Slic3r I could not get a successful print at 100 microns (with 200 micron first layer). I even re-ran my calibration and updated my live-Z and tried printing Marvin and the Prusa logo from the bundled models, and even those failed. So something is really wrong. Also, I foolishly played with the PINDA probe and have gotten myself into alignment hell with that.

The more I stare at my whole extruder block something looks a little off. I'm wondering now if something has loosened up. I do recall when I did initial assembly one of the screws that fit the back of the block to the front didn't grab threads properly but the rest were good and tight. Maybe it has finally shaken itself a bit loose.

Fortunately I have a back up printer (lulzbot mini), so I'm thinking about printing new pieces for the extruder block and re-assembling it.

Re: 200 micron vs 100 micron

Slic3r has the option for setting first layer height, where as Simplify3d does not (you have to use multi-processes to have different config for different layers).

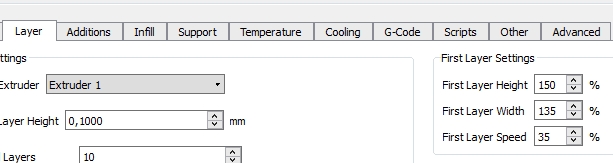

I think you are wrong with this. Inside the Tab 'Layer' you have three settings to change the behavior of the first layer.

Re: 200 micron vs 100 micron

Slic3r has the option for setting first layer height, where as Simplify3d does not (you have to use multi-processes to have different config for different layers).

I think you are wrong with this. Inside the Tab 'Layer' you have three settings to change the behavior of the first layer.

first layer settings.jpg

Oh yes, fair enough. I get the different terminology in the various slicers confused. I am certain that I had the first layer height set to 150% the entire time I ran into these problems. So even when I was trying to print at 100 microns, the first layer would be 150 microns which is should be within the limit suggested by the firmware.

In any case, I reached a point where I couldn't properly print even the Prusa logo from the SD card that ships with the printer, and that says it's at 200 microns. So I think giving the beastie a once over would be helpful because something is clearly out-of-whack.

Re: 200 micron vs 100 micron

Sounds like the bed my need a hard core cleaning!