Random filament failures in the hot end

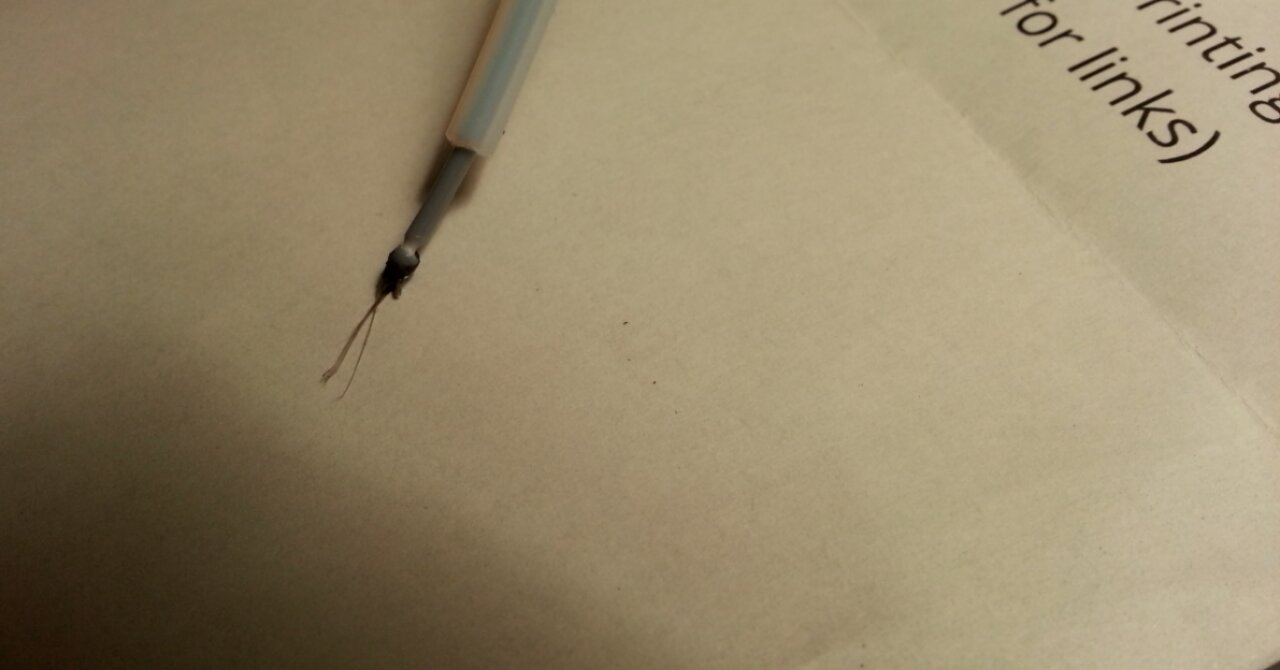

I've finally figured out with the help of the forum posts that I had installed the wrong PTFE tube in the hot end, I ended up with two and sure enough I managed to install the wrong, larger inner diameter tube. I'm still getting the occasional failure so I thought I would post this picture of my later jam. I've been clearing them by just preheating the hot end and feeding the bad blob through. I'm curious though any ideas of why I'm getting this filament blob?

1. Small (1.75 or so mm) ptfe tube in in the hot end

2. running inland PLA at 205C

3. Load, run, then oozes some but not as much as when the run will be successful

I've read about some hot ends needing to be taken apart, having the nozzle taken out, repacked with thermal paste, and then reassembled. Yesterday the printer ran great and has been finishing 14 and 6 hour print runs.

Jamie

Re: Random filament failures in the hot end

Hi Jamie. Does this happen when there are a lot of retracts?.

I had an issue of this nature. So i upped the temperature the blockages stopped nit o got awful stringing... then someone suggested reducing the retraction length and lowering the temperature... and the blockages stopped.

This was before linear advance. So the situation may be slightly different. Try something like 1.5mm retraction instead of the default 4mm.

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK