PVA vs BVOH

Hello!

I did some prints with PVA and I found it very hard to print with. Needed slow printing, didn't stick well to the bed or itself.

Now I am running a print with BVOH support material and the difference is huge. It is a lot easier to print!

Just wanted to share my experience here. I know BVOH is a lot more expensive, but from what I see now I am glad to pay the difference when seeing the ease of printing with it. Guess my PVA won't see much use anymore.

Re: PVA vs BVOH

This link below caught my attention when it comes to "water soluble" support projects. I didn't realize the 3D printers were capable of this, but after seeing how it's created and how water soluble supports work I can see the endless potential.

We just have to get good at CAD.... By the way I'm not sharing the link to advertise the printer, just to show the content. Sorry Josef if this isn't allowed, just delete it.

Re: PVA vs BVOH

Joris, that's amazing, what settings are you using with your BVOH? i kept getting jams (from the BVOH residue inside the nozzle) and if not jams it would poorly adhere to the previous layer, im about to return my BVOH to Amazon but i'll give it another try... i ran mines a default setting, and maybe 5 degrees hotter. Thanks in advance.

Re: PVA vs BVOH

This is the Verbatim BVOH I got from the Prusa shop, and I just run it through slic3r Prusa Edition with all settings to default basically.

FYI I ran the same model with soluble support interface setting yesterday but there were still supports attached to the model.

Re: PVA vs BVOH

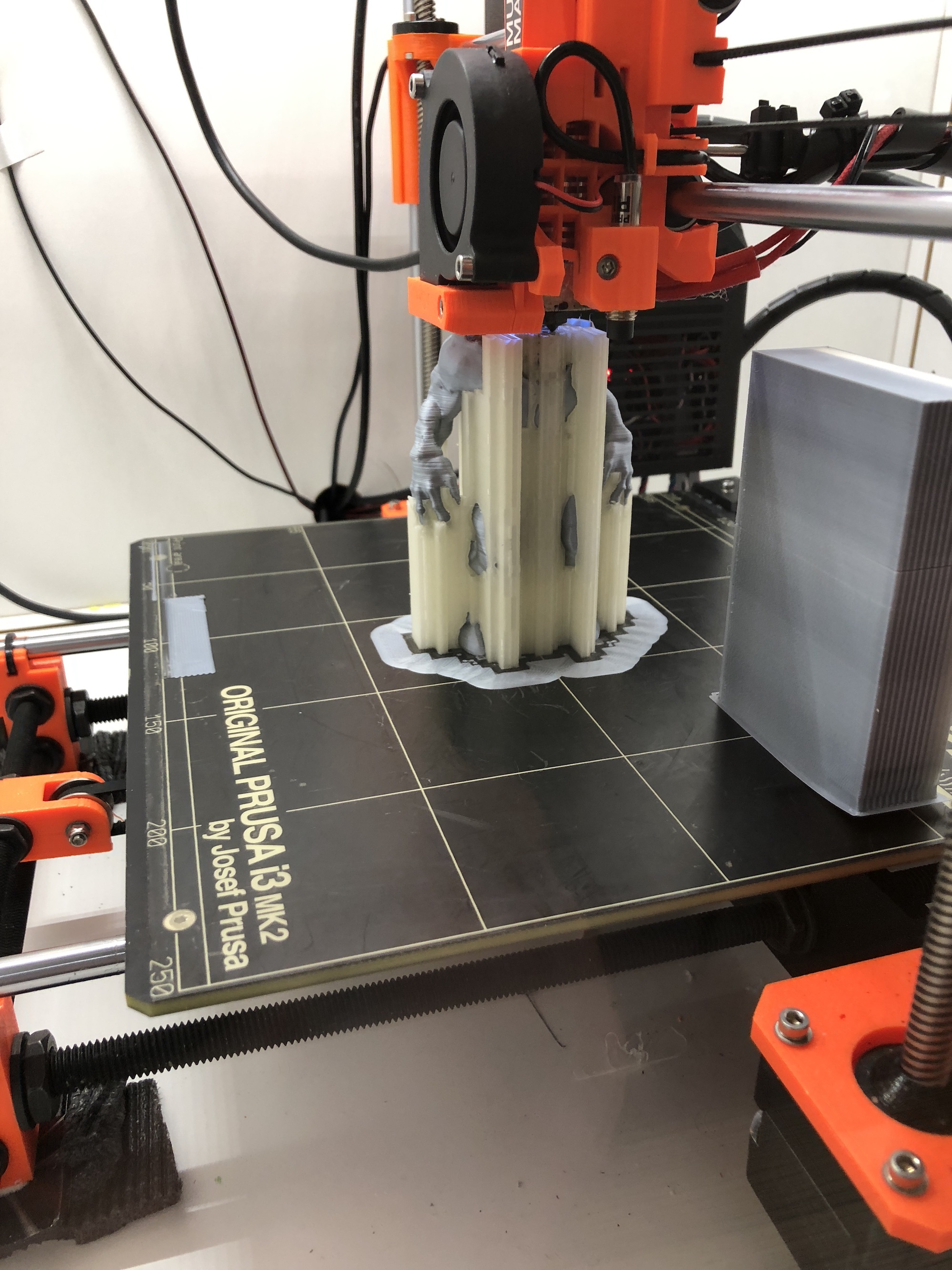

TBH the purge block is making me a bit sick though (figuratively speaking). There is more material in the purge block than in model + supports combined 😐

And I know the explanation always is "but if you print 10 models the purge block would be the same!". True that, but I am not running a factory here, so that argument is of no relevance for me.

Re: PVA vs BVOH

Joris, that's amazing, what settings are you using with your BVOH? i kept getting jams (from the BVOH residue inside the nozzle) and if not jams it would poorly adhere to the previous layer, im about to return my BVOH to Amazon but i'll give it another try... i ran mines a default setting, and maybe 5 degrees hotter. Thanks in advance.

Where are you from?

Re: PVA vs BVOH

I've been using BVOH and it simply just works (I've never tried PVA because of it). I've had a few problems with the purge tower splitting, which is odd, might just be a the other filament causing issues (hatchbox gold).

Make sure to use "SOLUBLE INTERFACE" in Slic3r, as you already know it's insanely expensive and this is a must.

Re: PVA vs BVOH

TBH the purge block is making me a bit sick though (figuratively speaking). There is more material in the purge block than in model + supports combined 😐

And I know the explanation always is "but if you print 10 models the purge block would be the same!". True that, but I am not running a factory here, so that argument is of no relevance for me.

I've been concerned for the wasted material also. At some point you could buy a printer that has two extruders with the product cost you throw away. Has anyone heard of the PRUSA team considering a dual extrusion setup? Using that with the MMU would be good.

In another post I came across a link from E3D about their "Kraken quad extruder". Is it possible to integrate into the PRUSA design for an upgrade?

Re: PVA vs BVOH

Let me just add that I know the waste is due to ANY SINGLE EXTRUDER system and I hope there to be an upgrade later, dual or quad.

Re: PVA vs BVOH

There are a few independent extruder printers on the market (the best one being the BCN Sigma), and they seem to do a good job of limiting the waste, but all other dual extruder single head systems depend on purge blocks/ wipe towers / ooze shields (Ultimaker for instance).

What's nice with a real dual extruder setup is that you can print 2 materials that have completely different printing temperatures, without issues.

But we are talking a very different price point here (check the price of the BCN Sigma and compare it to a Prusa 🙂 ).

Re: PVA vs BVOH

It’s nice to see your succes with BVOH. I have done some really excellent prints using 4 PLA colors but when I use my BVOH the parts come out really brittle and separate really easily. I’m not sure if the BVOH is hanging around in the nozzle or what. I’m not sure what to try. I bought the multimaterial mod mainly for soluble supports but have not had good luck. Would you mind sharing your gcode? Perhaps I could give it a try. I am also using verbatim BVOH I bought, its from amazon though so maybe it’s old or something. Was sealed really well.

Re: PVA vs BVOH

Here you go.

Config is:

PLA in extruder 3

BVOH in extruder 4

This one is generated with Soluble Interface settings.

Also, use gluestick for the purge tower. I had it loosen without it.

I have a filament dryer, but I guess an oven would do the job as well.

Re: PVA vs BVOH

I tried printing your GCODE and it just stopped about 6 hours into it. The issue was still there though that when I print using a soluble support, the part is really brittle. I wanted to try further testing but I cannot get my MMU printer to print anything anymore even in single material mode unfortunately.

Re: PVA vs BVOH

I guess it's a problem with your printer then.

Too bad, hope you can figure it out :/

Re: PVA vs BVOH

Make sure your filament isn't getting exposed to too much wet air. I found any filament exposed outside my dry box becomes very brittle both in feeding and printing. You can bake the filament on low temperatures to help, but I usually just cut the brittle material out and start over.

Re: PVA vs BVOH

Also I'm encouraged by your experience with BVOH -- I had ordered some eSun PVA before upgrading and oh boy is that material touchy. I've got it printing now with a lot of parameter tuning but my feed motor keeps jamming after 3-6 hours and I can't adjust the tension any more or it won't push the filament down or any less or it won't feed at all because the stuff is so soft. Might need to redesign the feeder plastic to not give the filament so much room to get jammed... Or I'll just pay 2.5x the price and use the BVOH I am ordering now based on your experience.