MMU still just not ready for sale

have exacly the same experience. This MMU is just not good enough !!!!! Please make a FREE upgrade to a solution that works.

Am I the only one who have to speak out on this?

I don't understand why some many people are not making a case out of this. I have never paid for a system that are this much unreliable. This is just not good enough Prusa !

This is like our danish fairy tale from Hans Christian Andersen: "The Emperor's New Clothes". This is NOT a working printer solution !! - analogous to the fact that the Emperor from the fairytale was told that he had new dresses. ( https://en.wikipedia.org/wiki/The_Emperor%27s_New_Clothes )

PRUSA: We don't have a working MMU printer ❗

I look forward to see an upcoming solution for:

1) Thickenings of filament that comes out of the heat-break and blocks when they are tried to be pulled back through the metal pipes. The intention was to make sure it came back to 1.75 mm in diameter again. This doesn't work! It just blocks and stops and the extruders are not able to pull the filament back at all. "Clogging" is what this is called.

2) Stringing all over everything. With ugly strings of melted filaments everywhere. Primary due to the Bowden system I believe. The printer has even already been upgraded from i3 MK2 to i3 MK2/s which should take away som tolerances and make it more precise. Which means that I have already putted a lot of money in this - and hours - and now i'm in a much worse position as when it was "just" a MK2. At that time the uptime was MUCH higher - and It could print - you could leave it printing alone. Now nearly all jobs are either of low quality (stringing) or unreliable - especially when using multi material. PLA is nearly not working- better LUCK is present when printing with ABS. But still not what is expected for such a released product.

3) Blocking of the Y-splitter- (end near to hot-end) Here either fragments of filament or strings from an already retracted filemant causes the new filament not to being able to come through when expected for printing. This again blocks everything. And you can stop and through out what has been printed already.

4) Linear Advance for MMU doesn't simply not work correct!!

5) A new upgrade for MMU says it have "a better user experience" . After contacting Prusa they give no clues at all. If this upgrade are expected to give a better experience, I think they admit that this current MMU solution have some design flaws. But NOBODY admits this! - This design is so much NOT READY for sale yet- to my opinion.

6) some (including myselves) have had Hot-End, and Y-Splitter exchanged due to some initial QA problems. (in fact wrong hot-end was sent out). Why should every frustrated person, who have received this very bad kit, - search for such information by themselves. Why is this not informed to every customer to help them out of this frustration. What else has not been informed?. I still have a system not working! In fact the new Hot-End which can be recognized as it have Red/Orange Thread Locking glue which is visible on the heat-break. And this is like loctite. It locks the heat-break together with the heat-block. Am I advised to break the thread-lock to see if everything is fine in there - Or can I believe 😕 that this is not causing any of my troubles? How can I know?

7) The load and unload Menus don't have a possibility to just keep the filament in there. EVERYTIME when you have to stop/cancel the current print job - you need to decide how many extruders that you want to unload. You simply don't have the possibility of NOT TO unload anything. You are forced to UNLOAD and LOAD every time you stop the current job. And trust me; This happens nearly 90 percent of the times when something goes wrong - and therefore it is dull, that you have to take the whole filament all the way out and put in all the way in again. In the meantime, due to the necessary STOP of print - also the temperature for both heat-bed and extruder are being deactivated. Also in this very unreliable solution. There should be a possibility to select to keep the temperature there for both the extruder and the heatbed. Otherwise just can just add several minutes to each take on making it to print correctly. They should try to let 20 persons in the factory print using more than one filament - and then learn from the outcome from this. Why haven't this user interface been optimized so that you don't have to waste more time than is already needed with this MMU.

8) The metal tubes inside in the Y-splitter is not necessarily aligned with the fitting for the PFTE tubes and the inside of the Y-splitter. This causes troubles according to a lot of people. Why haven't this been solved yet. Then fix it and make sure that they are centered by design!

9) Extruders. Even though it's a new double wheel extruder (Bondtech extruder gear). It seems a little (read VERY) odd, that you many times hear the annoying noise from the gear teeth slipping in between the two wheels. The pressure to make sure that they get in touch to each other is done with the spring tension that you are making on the two screws. These screws needs to be nearly not making any pressure??? And if tightened too much (which is nearly nothing) then a lot more troubles occur!. The annoying noise/sound is very often heard, when starting a print job and it's making the prime stripe in the outer peripheral of the heat bed. I have mentioned this to Support. Also this is just "normal" according to them? Who will design a gear where the teeths are slipping ?? This is not the best starting point for the rest of the problems the MMU upgraded printer has. Ín fact I would expect this to be one of the most important parts when dealing with extruding and extracting which is hysterical critical in this design. Due to all the clogs in different parts of the printer, the noise from the extruder gears can't be a healthy condition for the mechanical parts!? The noise is the thing called "Slipping and Grinding" This is simply not good enough!. Tensions screws that are that sensitive !. There are nearly not screwed in - and a quarter of rotation makes a huge difference. Also here to hysteric by design. Every engineer would have designed this in a way, so that the screw/screws was screwed into the middle to begin with as a starting point. And from here, you could adjust either out or in from that to either tensioning or loosening the spring force.

10) Filament and types of. Prusa and others keeps telling (me an others)- Just use "original" filament. This is what I always do, when dealing with this MMU thing. Just look at my the order history - I have bought a lot (many) filaments from Prusa. But in this situation - I can't even use it for anything than just throwing failed prints out !! Fix it instead!?

11) Why not playing with open cards PRUSA and admit this sucks !!! And INFORM INFROM INFORM. That's the best way to help your customers to get back the believing on the brand name "Prusa" I have heard so much that nearly everyone gets different kind of "hidden" hints and exchanges that helps each person out individually ?????? Come out from your hiding - Solve it and INFORM. Look at these four items: https://www.livechatinc.com/blog/customer-service-problem-solving/ Someone have been there before!

4 Steps to Effective Customer Service Problem Solving:

(Problem solving is a mindset, not an ability)

To me it looks like you have failed on every each on these! That's thought-provoking!

12) And one last thing here. I have also pre-ordered the MK3. In the last past of days I have seen a lot of scary images from parts that people have already been received. Here it looks like that Prusa has lowered the print quality to make more parts in the same time (why else lovering the quality from the MK2). Prusa !!! This is not the way do handle big order backlogs and a still have a possibility to earn fast money!. This will stop your business in the end. Now stop up !! Fix the troubles that are there already - and don't mess with your quality - just a good advice for free!

Point: Fast and cheap --> low quality

Prusa - You are more than welcome here at my address in Denmark - You can learn from my printer if you don't have others like mine. You can for free get the experience that - will for sure help others. I will brew you a nice cup of coffee, if You happen to pass by. A will also arrange a piece of Danish 😉

HKOCH - Happy new year by the way ! (and a hope for a upgrade/exchange for my unreliable MMU upgrade) 🙁

Trust me, I'm an engineer 🙂 Always do your best. What you plant now, you will harvest later

Re: MMU still just not ready for sale

Unfortunately, I can't disagree with many of your points. I too, am disappointed in my MMU, I *really* like the promise of the upgrade, but after every jam, I curse and wonder why I don't just take it apart and go back to the original stock MK2s setup. Oh yeah, because than what did I pay $$$$ for?

I'm most disappointed with the apparent lack of support from PR on the MMU.

Re: MMU still just not ready for sale

me too.

I like soooo much my Prusa MK2, and trust in Prusa that i purchase the mmu and pre-ordered the mk3.

mmu has been a total failure, even after a replacement of hotend.

i think prusa must to honestly inform users and make something to fix the problem.

praying for mk3 will be different.

saludos,

antonio

Re: MMU still just not ready for sale

The MMU has been my biggest regret. I wouldn't mind experimental 4 color printing if it didn't also ruin my single color quality.

Re: MMU still just not ready for sale

Try this, it took care of many of the problems you're describing. It's still in testing stages but initial results are looking good. Check out my topic for more detail.

Re: MMU still just not ready for sale

I am very sorry to hear you are having issues. My MMU experience has been very different. It took me a bit to get it dialed in, but it has been very robust since. I have printed 100s of multi-color items and it has been very reliable. I routinely do prints longer than 30 hours, and a few over 50. I tend to do many prints on the platform to reduce the ratio of the purge tower to printed object. My printer has been running much of the time since I got it.

Judging by the number of photos of MMU parts on the web my case must not be that rare.

Clearly the frustrated cases (including you) are much more common than they should be, and these forum pages are full of hints to solve your issues (it did for me when I was getting it dialed in.) Some of these will result in design improvement for future versions. I do believe things will get much better in time - this is a new capability. Early adopters of all types often plow the path for the future users. One to watch is here:

https://shop.prusa3d.com/forum/original-prusa-i3-mk2-multi-material-f26/monoplexer-and-multiplexer-redesigns-no-metal-part-t12801.html

I upgraded to Linear Advance on my MMU, and it works flawlessly, and I am printing much faster than before. I don't understand your point #4.

I have done single color printing with PETG and PC since the upgrade. Works great. I do lament the loss of flexible filaments due to the bowden set up, but I knew that going in.

Again, I agree with you that the number of frustrated users of the MMU is higher than it should be, and improvements are needed. However, there are quite a number of us who have been using it very heavily and robustly (after we got it figured out - that was frustrating, but this forum helped me out a lot).

I do think the MMU is more sensitive to filament quality than the single extruder. I stick mostly with Hatchbox and it has been very reliable for me. A few excursions to other brands were mostly okay, but a couple were just more prone to clogging.

A few things that have helped me (your experience may be different).

1) Drop the extruder temps by 10deg from what you were doing before. This prevents the filament from being molten when it gets into the "cooling tubes". If it is molten in the tube, it will very likely solidify and clog. (I have not put my machine back in the enclosure since upgrading, and fear the added heat will make for clogs. Will likely put it back in in the next month or so - as current projects get finished and I have time.

2) Make sure the extruder tension springs are just barely engaged with no filament in it. Just barely touching the spring. If this is tighter, the filament deforms in the extruder, and will clog down stream (likely in the cooling tubes).

3) Make sure the spools can feed well. I don't like the included box. Built my own. Rolls hanging on a PVC tube.

4) Bevel/chamfer on the PFTE tube is important.

I am very sorry the number of frustrated cases is so high, and I hope there will be future improvements to eliminate that, but I am VERY happy with my MMU. Printing multi-color things has really changed the game for me.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: MMU still just not ready for sale

Aaron,

A couple months ago, I felt the same way you do in your post. Now, using my MK2s w/MMU is an exercise in frustration. With no clue what changed in the meantime.

Nearly every print ends up printing air as the filament jams in the chamfered PTFE tube. Even on GCODE I've used dozens of times in the past. I've rebuilt the hotend several times, replaced PTFE tubes, nozzles, heatbreak. Tried every filament brand I have (hatchbox, filamentum, taulman, etc). I've scoured the forums and tried all the tricks (tightening the heatbreak with the PTFE tube seated, etc). At this point, I'm considering taking the MMU off completely.

I'll paste from a previous post I've made:

I am getting super fed-up with this issue at this point.

I've tried every conceivable slicer and slicer setting.

I've tried inconceivable slicer settings.

I've rebuilt the entire hotend.

I've ordered replacement heatbreaks, ptfe tubes, steel tubes and paid the huge shipping costs.

Lately, I can't even get 50% of my single-filament models to print anymore. I almost wonder if this is essentially a heat-creep issue. I think my next step will be to break into the extruder design and super-cool the heatsink. But I'm not hopeful.

I really hope Prusa and Co. haven't responded because they've been busy fixing the issue and any day now they will swoop in with the solution. Or more likely, they're putting Mk3's in boxes... I would've ordered one myself, but this MMU has soured me lately.

Re: MMU still just not ready for sale

Aaron,

A couple months ago, I felt the same way you do in your post. Now, using my MK2s w/MMU is an exercise in frustration. With no clue what changed in the meantime.

Nearly every print ends up printing air as the filament jams in the chamfered PTFE tube. Even on GCODE I've used dozens of times in the past. I've rebuilt the hotend several times, replaced PTFE tubes, nozzles, heatbreak. Tried every filament brand I have (hatchbox, filamentum, taulman, etc). I've scoured the forums and tried all the tricks (tightening the heatbreak with the PTFE tube seated, etc). At this point, I'm considering taking the MMU off completely.

I'll paste from a previous post I've made:

I am getting super fed-up with this issue at this point.

I've tried every conceivable slicer and slicer setting.

I've tried inconceivable slicer settings.

I've rebuilt the entire hotend.

I've ordered replacement heatbreaks, ptfe tubes, steel tubes and paid the huge shipping costs.

Lately, I can't even get 50% of my single-filament models to print anymore. I almost wonder if this is essentially a heat-creep issue. I think my next step will be to break into the extruder design and super-cool the heatsink. But I'm not hopeful.

I really hope Prusa and Co. haven't responded because they've been busy fixing the issue and any day now they will swoop in with the solution. Or more likely, they're putting Mk3's in boxes... I would've ordered one myself, but this MMU has soured me lately.

I absolutely agree!

Look in the forum about "Blockage troubleshooting". This has 277 answers (placed in 28 tabs) and 11732 have viewed it at the time being.

This is all about blockage on the MMU !!! This says it all. Where is Prusa. Why is this something that we have to discuss. Where are the designers and manufactures in this? Yes I know that it's open source. This should not take away the product liabilities for a company who sells kits or build printers.

This is simply not good enough. Prusa I think that you acts like an Ostrich that hides its head in the sand.

Prusa come on!! Put some effort in this and either stop producing this anymore or solve the problems. Fix it please!

Trust me, I'm an engineer 🙂 Always do your best. What you plant now, you will harvest later

Re: MMU still just not ready for sale

I'm running a Prusa mk2s MMU myself and I'll share my experiences.

In short: in the beginning, lots of issues, even with loading filament (I had it come out between the gears and on the side once while loading!). Then after a while I got used to how the loading works so that was ok now and is no longer an issue.

Spring tension: I agree. Completely ridiculous. You have a "finetuning" range of about 0.5 revolutions. Moreover, if you happen to loosen the thing completely the nuts can fall out.

Filament loading/unloading. There is room for improvement there but I don't know if they can without additional sensors. What annoys me the most is that I cannot unload filament that isn't even down in the hotend but just sits somewhere in the y splitter because the nozzle isn't heated up! I don't need to heat up the nozzle to remove that filament!

Extruder clicking. Same experience here. At the start of the purge on the front of the bed some very bad extruder clicking, but after that all runs perfectly fine. Every time. Why is the extruder clicking like that?

Purge block. Use gluestick! I had the block loosen once 19 hours into a 24 hour print.

Soluble support: PVA was a disaster for me. Very bad adhesion (fresh out of the bag). BVOH prints heaps better.

The real annoyance for me however is the stringing. I don't know why it is (no expert) but I had perfect prints before the upgrade, and now I always need to remove stringing.

MK3 is pre-ordered, but I'm going to keep that printer single material. MK2S was a joy to use and great quality prints.

Concerning clogs. I had a lot of issues with clogs related to my enclosure. PETG/PLA prints all failed because of heat creep.

Re: MMU still just not ready for sale

Prusa come on!! Put some effort in this and either stop producing this anymore or solve the problems. Fix it please!

You don't know what they are doing.

If, as someone stated here, they agree that mmu is not "production ready" and they pull it they'll have heaps of people claiming to get their money back.

If they think it's ok but there are still issues that need to be ironed out they will be working on it but I don't presume we will hear anything until they come up with something, as to be able to work on their own terms, and not being bombarded with "suggestions" from "internet people".

For me as it stands right now my only regret is the stringing. Besides that the system does what it's supposed to do.

Re: MMU still just not ready for sale

About the Bowden and stringing. The whole stringing problem started when adding the MMU to the MK2/MK2S.

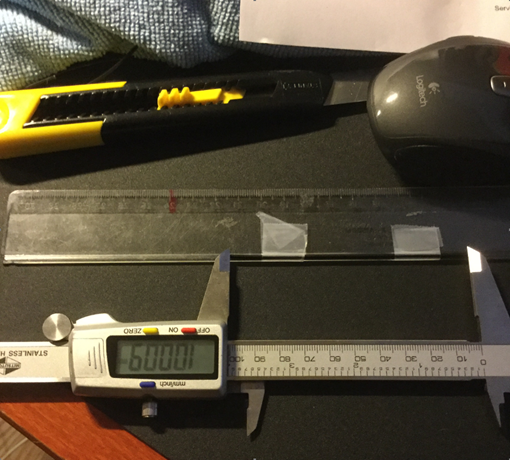

Both BCN3D, MAKERBOT, ULTIMAKER all uses the Bowden principle without these kind of Stringing problems. So it shouldn't be something to do with the use of Bowden itself, but something of how Prusa control's it in the firmware. I believe that it's something to do with Retraction, Over-Extruding, Extruder Mechanical design etc. or the tolerences of the Y-splitter, PFTE tube inside the Hot-End do to?. I have made tests with known length of filament (100 mm) and checked this against the gearing in the Prusa Bondtech design to look if some of the reasons is something to do with over-extruding . I had to adjust the EEPROM value given by the firmware from 140 til 138 steps/mm to have the correct feed asked for by the print job (GCODE).. That helps a little. But this is not removing all problems. Again. I would have expected these kind of observations had been done by Prusa before shipping them. And now after 6 months of frustrations this and all my other items listed in my previous comment are still not solved by Prusa?

Trust me, I'm an engineer 🙂 Always do your best. What you plant now, you will harvest later

Re: MMU still just not ready for sale

Prusa come on!! Put some effort in this and either stop producing this anymore or solve the problems. Fix it please!

You don't know what they are doing.

If, as someone stated here, they agree that mmu is not "production ready" and they pull it they'll have heaps of people claiming to get their money back.

If they think it's ok but there are still issues that need to be ironed out they will be working on it but I don't presume we will hear anything until they come up with something, as to be able to work on their own terms, and not being bombarded with "suggestions" from "internet people".

For me as it stands right now my only regret is the stringing. Besides that the system does what it's supposed to do.

No correct joris. I just don't know what they are doing - that's my whole point - also here many month (~6 month in my case) after with a printer nearly not working?? Why do most of us have to be hold in total uncertainty

Trust me, I'm an engineer 🙂 Always do your best. What you plant now, you will harvest later

Re: MMU still just not ready for sale

For me as it stands right now my only regret is the stringing. Besides that the system does what it's supposed to do.

It is very interesting. I get no stringing at all. Less than the original MK2 did.

I have seen the photos of the excessive stringing with the MMU, and I get NONE. I have no idea what to attribute that to, as I have the same retraction settings and temps as y'all.

I think a lot of the issues with the MMU are around the tolerances of the parts - maybe I got lucky - but I can't figure out any reason that a tolerance would change the stringing issue. Jams, sure. Load issues. Sure. Stringing. Baffling.

I live in a very dry climate, but I really doubt that is a factor.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: MMU still just not ready for sale

Aaron,

A couple months ago, I felt the same way you do in your post. Now, using my MK2s w/MMU is an exercise in frustration. With no clue what changed in the meantime.

Nearly every print ends up printing air as the filament jams in the chamfered PTFE tube. Even on GCODE I've used dozens of times in the past. I've rebuilt the hotend several times, replaced PTFE tubes, nozzles, heatbreak. Tried every filament brand I have (hatchbox, filamentum, taulman, etc). I've scoured the forums and tried all the tricks (tightening the heatbreak with the PTFE tube seated, etc). At this point, I'm considering taking the MMU off completely.

I really feel that frustration. I hope I don't follow in your footsteps. I have been printing with the MMU since Sept 4, 2017 (not that long) but the machine has been running nearly continuously during that time.

UNTRIED ADVICE FOLLOWS - I HAVE NOT TRIED THIS

The interior surface of the PTFE tube seems to be a big deal in this application. And specifically the inner tolerances. Prusa has talked about these tubes being special made for them. If that is where your jams have been, it might be worth trying a "Capricorn" tube.

https://www.captubes.com/shop/

https://www.captubes.com/specs.html

The XS series is ultra low friction, and is sized to the smaller size the tube in our extruder is supposed to be set to. I recall reading that some of the original beta team used this PTFE tube with some success. If that is where you are having your jams, trying one of these (cutting it correctly, chamfer and bevel correctly) might be worth a try.

If I start having issues in my PFTE tube, I would try that.

--- EMPHASIS I have not tried this, but think it is worth a go ---

That said, I did buy a bunch of the XS series from Capricorn, with the intent of using it in my Bowden setup. My thinking here was the lower friction can't be bad, and the smaller diameter might prevent the bunching up that seems to prevent flexible filaments from working. I have not installed it yet, but my intent was to replace the Bowden tubes, and try flexible filament. I also bought some, in case my PTFE tube in the extruder when bad, I would make a new one out of this stuff.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: MMU still just not ready for sale

Aaron,

A couple months ago, I felt the same way you do in your post. Now, using my MK2s w/MMU is an exercise in frustration. With no clue what changed in the meantime.

Nearly every print ends up printing air as the filament jams in the chamfered PTFE tube. Even on GCODE I've used dozens of times in the past. I've rebuilt the hotend several times, replaced PTFE tubes, nozzles, heatbreak. Tried every filament brand I have (hatchbox, filamentum, taulman, etc). I've scoured the forums and tried all the tricks (tightening the heatbreak with the PTFE tube seated, etc). At this point, I'm considering taking the MMU off completely.

I really feel that frustration. I hope I don't follow in your footsteps. I have been printing with the MMU since Sept 4, 2017 (not that long) but the machine has been running nearly continuously during that time.

UNTRIED ADVICE FOLLOWS - I HAVE NOT TRIED THIS

The interior surface of the PTFE tube seems to be a big deal in this application. And specifically the inner tolerances. Prusa has talked about these tubes being special made for them. If that is where your jams have been, it might be worth trying a "Capricorn" tube.

https://www.captubes.com/shop/

https://www.captubes.com/specs.html

The XS series is ultra low friction, and is sized to the smaller size the tube in our extruder is supposed to be set to. I recall reading that some of the original beta team used this PTFE tube with some success. If that is where you are having your jams, trying one of these (cutting it correctly, chamfer and bevel correctly) might be worth a try.

If I start having issues in my PFTE tube, I would try that.

--- EMPHASIS I have not tried this, but think it is worth a go ---

That said, I did buy a bunch of the XS series from Capricorn, with the intent of using it in my Bowden setup. My thinking here was the lower friction can't be bad, and the smaller diameter might prevent the bunching up that seems to prevent flexible filaments from working. I have not installed it yet, but my intent was to replace the Bowden tubes, and try flexible filament. I also bought some, in case my PTFE tube in the extruder when bad, I would make a new one out of this stuff.

PTFE is kind of a self lubricating plastic, so jams here are less likely due to that, and more likely because of printed parts. So far I've seen a lot more people with jams in the extruder bodies and multiplexer, which is where I personally had troubles due tolerances of the printed part. Check my topic on redesigns for the multiplexer for why this happens if you are interested, I had problems from the start with my original multiplexer and have been going for about a week with no issues now.

Re: MMU still just not ready for sale

UNTRIED ADVICE FOLLOWS - I HAVE NOT TRIED THIS

The interior surface of the PTFE tube seems to be a big deal in this application. And specifically the inner tolerances. Prusa has talked about these tubes being special made for them. If that is where your jams have been, it might be worth trying a "Capricorn" tube.

https://www.captubes.com/shop/

https://www.captubes.com/specs.html

I tried that... not a solution for me

Re: MMU still just not ready for sale

Hi Forum,

My experience was that it just not works with the standard settings out of the box. I worked hard during a month and got it working in single mode, but not very reliable. The forum and the chat helped me a lot..... but I decided to go back to my always proper working MK2s.

I learned a lot about the principles Prusa used. And that is a good thing.

I really tried everything, the capcorn tube from USA, camfering, gearsspringsettings, other load/unload strategie (I think that is the major part of te issue) you name it, I tried.

So now I have some spare parts 😀 Must say , meanwhile I did a lot of thinking about making 4 color prints..... nah that's not what I will do. So my goal was set wrong.

So I told myself, stop with it, go back to your MK2s, print nice stuff and enjoy. Maybe in the future the MM back, you never know.

I still believe in Prusa, and yes the MM is maybe not the best choice for now, but heeeee if you want to go forward you have to take challenges and cross boundaries. If not, there was not a flourishing company called PRUSA

Yesterday I bought a used MK2s for my son, it is a second hand, almost not used. You know why it is sold? XYZ calibration failed and the guy will take no action to solve it. So every one has his limits.

That's my contribution about the MM,

Still a happy with my PRUSA

Frans

Frans Krau

Europe, Holland, Apeldoorn

Re: MMU still just not ready for sale

I have had the MMU upgrade for 5 Weeks now and its very hit and miss as to whether the print will complete without issue.

Tech support suggest Increase/decrease temps what filament etc etc.. Stringing was bad after the upgrade (Never an issue before the upgrade)

Prusa suggested increasing the retraction to 6mm (and that worked no stringing)

The jamming is the main issue for me...one print will be fine and you think your issues are fixed and then something else

I use the same mixture of filament I did before and again never had an issue.

I have asked Prusa to take the upgrade back (I know they won't) I guess the extra parts might come in handy (Will revert to the single setup as before)

I asked Support what filament I should use with the MMU upgrade. I use Prusa filament and its no different in my experience

Me

16:13

Are you telling me the MMU upgrade will only use certain filament makes ?

Michele

16:19

our PLA of course 🙂

Michele

16:19

the reason indeed is we provide optimal fine tuned pre-settings basing on our filament of course

Michele

16:20

the printer with of without MM will just work fine with any 1.75 filament but you really need to tune the best the filament settings especially on a sensible setup as the MM one

Re: MMU still just not ready for sale

Not trying to beat a dead horse, but download the redesigned multiplexer. It takes 5 mins to set up to print, and then you have a new part to see if it takes care of your problem.

This took care of ALL of my issues and there are other people who have had good luck with it.

Go to the topic!

Re: MMU still just not ready for sale

All,

I'm not sure that this adds a whole lot to the sad story. I have spent endless number of hours and nights as well to get the MM to work and only with very limited success (or rather unpredictable success). So, I won't re-iterate on this again. But for now (last 3 months) my printer has been put off line and is not used anymore. Basically I could not find more energy and time to keep trouble shooting.

What I would like to add is my disappointment about how poor service you get when trying to get things fixed:

As 90% of the reported issues have to do with the chamfered PTFE I decided to buy 5 new tubes from Prusa specifically made for MM version in order not to add my own skills (or lack of skills) in chamfering and cutting into the equation. I specifically told Prusa that I was using the MM version and that the tubes should be the ones made for them.

And guess what was sent? 5 tubes in the incorrect length and without chamfering.... Now it became my problem AGAIN to get it to work.

Back to Henrik Koch's point: When the shit hits the fan the best thing you can do as a company is to give great service, great support, honest suggestions for fixes etc. All we have is an extensive list of unstructured feedback from a lot of frustrated users. The lack of clear guidance from Prusa put my 3D printer to sleep and I can't see myself ever buying another Prusa printer again. My 12-year-old kid played for 5 full days with Ultimaker 2MM printer without any issues, without needing detailed trimming - it just worked out of the box.

I also spent a couple of hundred $ on Simplify3D which worked GREAT with MkII. Best slicer interface ever that my son could even use. Given all the issues with MM version I can certainly understand why Simplify3D does not want to support the MM version. So, yet another few hundred $ wasted.

Anyhow: My next 3D experience will be with another brand. If we start sharing suggestions for best alternatives in this forum it may wake up Prusa's communication skills?

Over and out from another engineer that felt in love and ended up being so disappointed