Jamming in PTFE tube

Good Afternoon

If you have been ready any of my other posts you know I have been working on this project with my terminally ill son. Sadly we had to stop as his condition worsened and he had to be in the hospital. God has seen his way to help my son through that rough time and he is home and in high spirits. And now that he has the energy we are at again. So on with our questions.

So recently Prusa sent us a replacement PTFE tube for my hot end. After replacing it I tried to do a single extruder print. As soon as the extruder tried to prime we could hear the extruder slipping. So we ejected the filament and removed the multiplexer. We tried to hand feed the filament into the ptfe but it took a lot of force. We cut off the previously fed piece back to a fresh area and then tried to feed that fresh piece in and it went in with little effort. So after some discussion we assume one of two things is going on.

A. The extruder gears are causing the filament diameter to increase enough that it is too big for the hotend PTFE thus causing the need for more force. Is there a procedure to finding the Goldilocks setting for the extruder pressure?

B. The PTFE is constricted by the PTFE fitting, possibly by an error during assembly. When we assembled it I we left a couple of turns out on the hotend, inserted the PTFE to the bottom and then tightened the hotend so that the fitting was extended out fully so the tube could not slip. Do too many turns cause the fitting to compress the ptfe more than it needs to be?

TIA

Michael and Andrew

Re: Jamming in PTFE tube

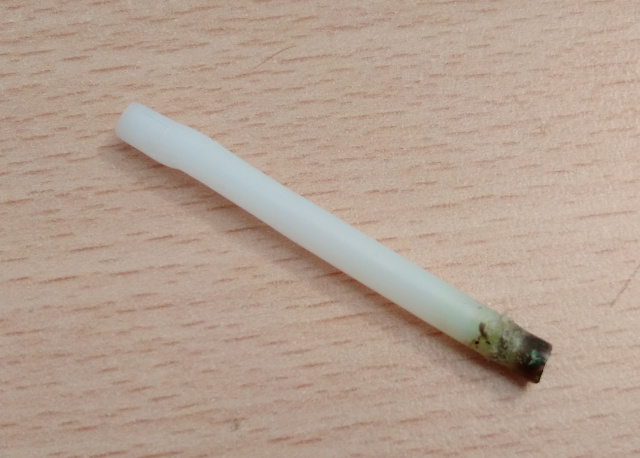

yes too many turns could deform the PTFE

PJR explains the process better than me...

I copied the enclosed image from this thread

http://shop.prusa3d.com/forum/original-prusa-i3-mk2-multimaterial-f26/blockage-troubleshooting--t4643.html#p34104

may I suggest you have a look through that set of posts!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Jamming in PTFE tube

Thank you. Luckily they sent us more than one tube so if we did deform it we can try again a bit more gingerly.

Re: Jamming in PTFE tube

So I finally found the time to rebuild the extruder.. It is working as I would expect except for one issue. I tried printing the 2MM calibration gcode file. During the print filament is extruded as expected. However there is a sound of it skipping. Like the feed rate is too high or the bondtech gears are not tight enough. The flow at the extruder looks to be proper. Any thoughts on this? I've been heading the right direction and hate to go backwards..

Re: Jamming in PTFE tube

Skipping = check your filament spools, tension and feed paths.

Make sure the spools are feeding smoothly.

When you unload the filament, does it show much damage from the drive gears?

Remove the MUX. Does filament pass through easily?

Heat the nozzle; can you manually extrude easily?

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Jamming in PTFE tube

If I raise the Z axis and manually feed filament from the controls it extrudes freely. this is what made me think the feed rate was too high since when actually printing there is resistance.. I will look at the possibility of resistance from the spool. Are there any tips for making the spool roll easier if this is the case?

Re: Jamming in PTFE tube

The V6 can handle over 10mm^/s melt; that's about 4.5mm/s or 270mm/min.

It's unlikely that any G-code requires a faster feed than this, unless your slicer parameters are very wrong.

I never found that the supplied spool holders worked particularly well; you will find a few pictures on here of my printer spool holders.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Jamming in PTFE tube

I didn't slice these files. They are the sample ones supplied by Prusa. Interestingly enough I have not been able to figure out why it is stuttering. But I did have an interesting outcome from an experiment. I used the silver PLA that came with the printer and I chose the 2MM calibration gcode that was sliced for ABS. It printed out perfectly. Not a stutter or a skip. Does this mean my PLA could be bad, maybe with some moisture in it?

Re: Jamming in PTFE tube

I didn't slice these files. They are the sample ones supplied by Prusa. Interestingly enough I have not been able to figure out why it is stuttering. But I did have an interesting outcome from an experiment. I used the silver PLA that came with the printer and I chose the 2MM calibration gcode that was sliced for ABS. It printed out perfectly. Not a stutter or a skip. Does this mean my PLA could be bad, maybe with some moisture in it?

This has happened to me before with PR Blue filament. During a print, I had to increase temp to 235 degrees to get it to feed properly.

Probably bad (or old) filament

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…