hungry Festo couplers

Is there a way to extract a short length of PTFE Tube from inside a Festo coupler?

the continuous swinging of the PTFE tubes, seems to lead to a cutting effect within the festo's and I now have three which are unusable, the last one failed in the middle of a 6 hour print, spilling metres of filament onto the floor, and Air printing, until I noticed the problem

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: hungry Festo couplers

I haven't found a way to do this as yet. If you do, please let me know.

I am fortunate in that I have a good supply of Festos. At one point I went through 7 in one week, but since I ordered the spares, I haven't had to replace one.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: hungry Festo couplers

I've not found a way either - had to throw them away 🙁

Re: hungry Festo couplers

My MMU is still new (and working great), so I have not yet experienced this issue - but will get spare Festos in preparation.

Having watched the machine for a while, I am considering printing a small square with four holes in it to "strain relieve" the PFTE tubes above the Festos with each other. I am not sure this will reduce the motion at the Festo, but seems like an interesting idea...

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: hungry Festo couplers

My MMU is still new (and working great), so I have not yet experienced this issue - but will get spare Festos in preparation.

Having watched the machine for a while, I am considering printing a small square with four holes in it to "strain relieve" the PFTE tubes above the Festos with each other. I am not sure this will reduce the motion at the Festo, but seems like an interesting idea...

Aaron, it's the rotational movement of the tubes due to the X axis movement (especially at higher Z)which cause the metal leaves inside the festo to cut a groove into the tubing.

If you are constantly printing at high feed rates, these leaves can also just give up.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: hungry Festo couplers

My MMU is still new (and working great), so I have not yet experienced this issue - but will get spare Festos in preparation.

Having watched the machine for a while, I am considering printing a small square with four holes in it to "strain relieve" the PFTE tubes above the Festos with each other. I am not sure this will reduce the motion at the Festo, but seems like an interesting idea...

Aaron, it's the rotational movement of the tubes due to the X axis movement (especially at higher Z)which cause the metal leaves inside the festo to cut a groove into the tubing.

If you are constantly printing at high feed rates, these leaves can also just give up.

Peter

Thanks. That makes sense. I will get there quickly as I am printing lots of large things. Have we found a brand of replacement Festo that is particularly good or bad?

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: hungry Festo couplers

Festos originals are best: QSM-M5-4 153304

But they are available from China: http://www.ebay.co.uk/itm/3D-Printer-Pneumatic-Straight-Push-in-PTFE-Tube-Fitting-Connector-4mm-10mm-OD-/252851175727?var=&hash=item3adf1ac12f:m:mVwpYxPLkltgbVDJR5bczTg (PC4-M5)

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: hungry Festo couplers

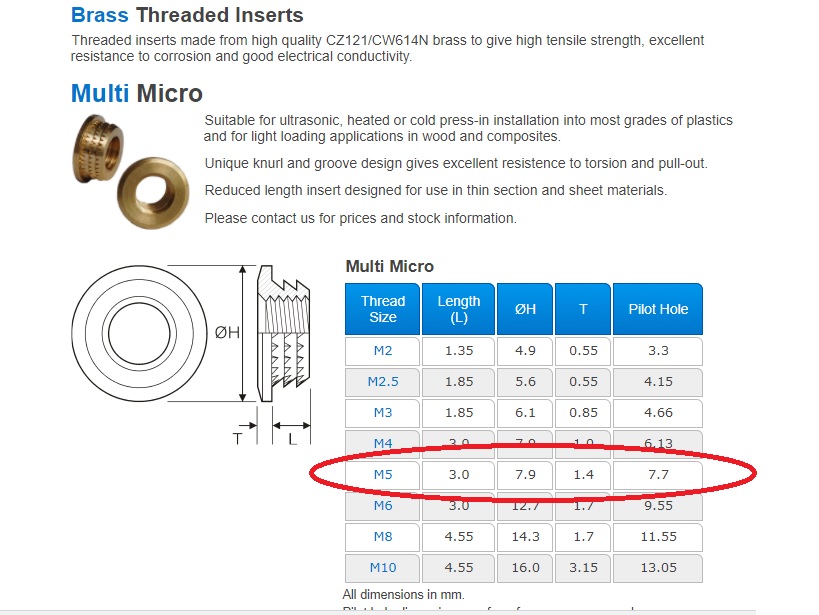

I'm currently reprinting most of my printers parts and I've wondered if anyone knows the partnumber of the metal threads that are inserted into the extruder and multiplexer parts for the festo couplers to be inserted?

Re: hungry Festo couplers

https://shop.prusa3d.com/forum/original-prusa-i3-mk2-multi-material-f26/festo-components-t6069.html

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: hungry Festo couplers

Could this be the part?

http://www.theinsertcompany.com/brass_multi_micro_inserts_for_plastic.php

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: hungry Festo couplers

Perfect thanks

Re: hungry Festo couplers

This may be a solution?

https://www.mcmaster.com/#94180a361/=19yi34o

Re: hungry Festo couplers

The best solution/fit appears to be joan's which references thebrassinsertcompany.com (link below)

They responded quickly and kindly with pricing information, minimum order of 50 with shipping would total roughly USD$ 128.40.

The heat insert solution requires altering .stl file but is only $12.

Doable but... Still looking.

http://www.theinsertcompany.com/brass_multi_micro_inserts_for_plastic.php

Removing PTFE from hungry Festo couplers -- A Solution

Here is a removal technique that has worked for me:

Insert a 3/32" pin punch in through the threaded end of the Festo. Tap it with a hammer. The PTFE tube comes out and the Festo seems to be undamaged.

(The actual diameter of the 3/32" pin punch is 2.25 mm. It is small enough to fit into the hole at the end of the Festo, but large enough not to fit into the PTFE tubing. Any rod about that diameter should work.)

Re: hungry Festo couplers

I hit this issue tonight. I was hoping it wouldn't happen, but it seems like an eventuality =/

I found a different way to remove the small bit of Bowden tube from the Festo coupler. I have a small pick tool that can be seen here: https://imgur.com/a/UDrto

My approach was to place the Festo coupler upside down on a table. Then while pushing downwards on the Festo coupler to disengage the internal leaves, I used the pick tool above to scrap inside the Festo coupler from the bottom of the Festo coupler. It took a bit of time, but I was eventually able to pull out the small ring of Bowden tube that can be seen in the picture above.

Re: hungry Festo couplers

I just wanted to add myself to this list and say that I've experienced this problem this week too. One of the Festo coupler ate through the tip of a Bowden tube.

Re: hungry Festo couplers

If anyone else hits this, please do leave a comment. It would be good to know whether this is a common issue or if we're somehow exceptional cases.

Re: hungry Festo couplers

I suspect that 3D printing results in more rotational motion on the Festo's than other uses do... for instance the CO2 pipe on my MIG welder just gets plugged in, pressurised, de pressurised and unplugged... never had a prublem with it.

the water pipes on my water filter never move, no problem

where as the printer is permanently bobbing from side to side, and the festo's eat their way through the pipes... like a pipe cutter...

the wider your model on the X axis, , the more viscious the cutting motion...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: hungry Festo couplers

My MK3 and MMU are on order, delivery at end of January, so I'm lurking and learning here.

I can well visualize the problem here described with the Festo's. Does it occur at both ends of the Bowden, or predominantly at one?

Though obviously longer than the Festo, might this fitting from McMaster Carr be a solution?:

Rotating Push-to-Connect Tube Fitting for Air Adapter, for 4 mm Tube OD, M5 x 0.8 mm Male Pipe, found at

https://www.mcmaster.com/#52115k221/=1ali5yv

I believe I have gathered that there is some way to adjust for the length of the specific path from the feed to the extruder nozzle but I don't know the details. It just occurred to me that I suppose I could look at the current MMU manual...

Re: hungry Festo couplers

I believe I have gathered that there is some way to adjust for the length of the specific path from the feed to the extruder nozzle but I don't know the details. It just occurred to me that I suppose I could look at the current MMU manual...

I took a quick look and didn't find it, so perhaps I dreamt it.