Filament jam deep in multiplexer

So basically since I got the MMU upgrade a couple weeks ago it has been finicky with the 2nd extruder feed path. I did all the troubleshooting I could and all the other feed paths have worked fine. It would work fine on e2 for awhile and then suddenly after the wipe of a different color it would just get blocked in e2 and no longer print only that color. I would have to take it apart to get the filament out of the multiplexer until this last print where it completely jammed both directions in the e2 feed path of the multiplexer.

Before you ask:

-Yes, I always cut the filament at an angle

-No, none of the PTFE tubes are burred

-No, none of the other feed paths have any resistance in the MMU

-Yes, I have tried removing the multiplexer, and pushing a piece of filament through to unjam whatever blockage there may be , the filament just bends because there is too much resistance

-Yes, I removed the PTFE fittings and steel tubes and tried again.

As near as I can tell, this is as far apart as I can take the multiplexer and the jam is still impossible to take out. Since it has been giving me problems from the start, I'm going to guess that this is a factory defect. Is there any way to get a new multiplexer comped and sent to me? Spent over $1000 on it between the printer (6 months old) and the upgrade and it should work for more than a week or two.

Re: Filament jam deep in multiplexer

get used to it. i have gone through the same issues. The entire splitter/ multiplexer needs a redo. i am testing a few hardware changes, if all goes well i will post it.

Re: Filament jam deep in multiplexer

Don't get me wrong, I love the MMU. I wouldn't even mind printing a new part for it, if I could do that without extra hardware. It just sucks that this happened and I'm down to 3 colors already.

Re: Filament jam deep in multiplexer

Is there a physical spec limitation for design considerations like where the feedpaths combine for proper filament retraction between colors? I could probably whip up something in the next couple days if I could get a current file of the multiplexer

Re: Filament jam deep in multiplexer

I had some success in removing a multiplexer blockage with a Knitting needle and sheer force.

(You can also try to soften the pla a bit by baking it at 70°c for 30 min under aluminium sheet, but do it at your own risk, and it didn't work for me)

I eliminate my problem by not using a certain plastic brand on my big mmu prints.

Re: Filament jam deep in multiplexer

Just an update:

Finished modeling a single filament replacement version for the multiplexer. I will upload pictures and the stl once I have tested it works.

I know it sounds weird going back to a single filament after purchasing the MMU, but I have a thought process behind it and I still plan to model a better MM multiplexer.

The multiplexer only needs a single screw and PTFE tube removal in order to replace it so it should be practically speaking, the easiest part to replace. If a jam occurs in the right place, it makes it to where not just a single extruders feed path is messed up, the whole thing will be out of commission. So if I print this single part then I'm not dead in the water if my multiplexer goes down and I can print another multiplexer with the single feedpath replacement. I'm even making it to where the brass PTFE connection piece threads directly into the plastic of this piece so that it should be easier to replace in an emergency (no steel tubes or press in brass fittings).

If all goes well I will post it and give out the STL.

Re: Filament jam deep in multiplexer

Wow ! Neat idea ! Please do keep us up to date !

Re: Filament jam deep in multiplexer

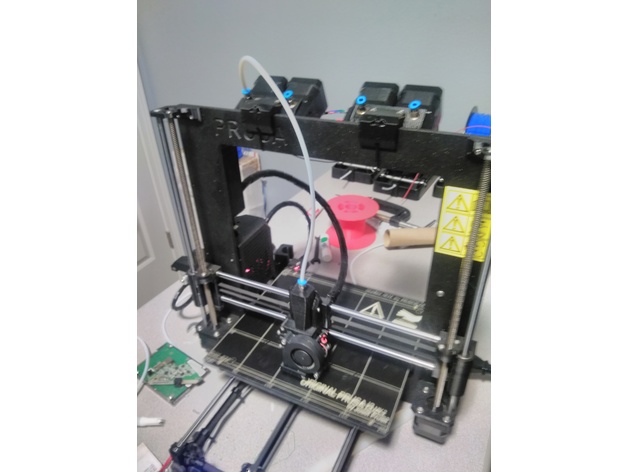

This is what I came up with. I essentially used the Prusa Multiplexer STL and modified it for a straight shot (no curves in the filament path). There are no steel tubes, and the top end diameter allows for the brass PTFE connectors to be easily threaded with needle nose pliers (mostly to keep it straight while threading).

I'm doing a test print of a 'Retropi handheld case' as I'm typing this, but the initial first layer or two and the loading of the filament went flawlessly, in fact, it seems there is less resistance than in the 'Extruder 1' path of the multiplexer that I used to print this part in the first place.

Since everything went so smoothly, I'm feeling pretty confident in uploading the STL. This file doesn't require supports. I printed it with 4 perimeter layers (minimum). I did print it 90 degrees off from the way that Prusa printed it (their layers go along the feedpath, while mine is perpendicular to it, meaning my layers have "ridges" that go along the feed path), which I thought might be a problem, but I think it worked out well in the end, as there doesn't appear to be any resistance.

I am currently working on the 4 feed path upgrade to replace the current multiplexer, possibly without steel tubing or the brass press fitted threads. If all goes well I will post it here.

Here is a link to the STL:

https://www.thingiverse.com/thing:2736405

If this picks up enough interest, I will start a separate thread.

Re: Filament jam deep in multiplexer

Okay, I finished modelling the multiplexer, it is currently printing to be tested. I will wait til I test it until I give you guys results, but here are some preliminary things I found while doing my redesign.

I don't think it is the angle of the feed paths that caused my problem. Upon close inspection of my broken multiplexer and close inspection of the stl of said multiplexer provided by Prusa, I found what seems to be the problem.

The diameter of the feed paths is roughly just under 2mm, so that the filament doesn't get bound but still is guided along the feedpath accurately. However, in the printed part, that path is widened substantially for the steel tubing to be inserted (I assume for feed path resistance reasons). It is not a snug fit for the steel tubes (they still move around quite a bit in there), so the path there is substantially wider than the feed path that you actually need to feed filament through. This on it's own wouldn't be so bad, but since at the bottom of the steel tubes, the feed path goes back to very small where all four paths combine, it causes a large sharp chunk of plastic to exist that can easily be broken off and cause the exact problem I'm having.

So my solution:

I modeled the part similar to how I did the monoplexer I just posted. That is to say that there are no supports, it has a flat top, and there are no steel tubes or brass fittings necessary for assembly. By not having the extra width in the feed paths from the steel tubing, it should make it to where that bulbous piece that can break easily doesn't exist. I notice that when you print with a .2 mm layer height, it seems to leave slightly rough edges vertically so I'm printing this particular multiplexer with .1 mm layer heights to reduce feed path resistance. As with my last file, I am enforcing 4 minimum perimeter layers and hoping for the best.

Here are some pictures:

If you look closely you can see where the larger diameter paths (where the steel tubes go) actually end up leaving holes between the feedpaths, which makes it weaker and adds the possibility of breakage.

My revised feedpaths just come to a point, which should be fine without the holes caused by larger feed paths.

Re: Filament jam deep in multiplexer

This looks like really good work! It's making me feel a lot better about the MMU I have on order to go with my MK3. Thank you for the very clear explanation of the findings and design philosophy behind the part(s).

Re: Filament jam deep in multiplexer

Another update:

I made a mistake while making the multiplexer.

Essentially I didn't account for the layers stacking making the feed paths slightly smaller than what they are actually modeled as, which made it to where my filament didn't fit through the feed paths. If you imagine two rings stacked on top of each other and then move the top ring even slightly from the bottom, it would make a smaller hole. This is essentially what happened with my layers.

I finished my remodel and made the paths slightly wider to account for it. It should be done printing soon. It should be close now, I hope to get the STL out by tomorrow!

Re: Filament jam deep in multiplexer

I finished the multiplexer and am printing my first test print as we speak. Here is the link to my first attempt at a revised multiplexer.

https://www.thingiverse.com/thing:2740929

I'm going to post a new topic that goes into more detail about the monoplexer and multiplexer that I have redesigned, so I'll spare the long post here.